Balsam pear seed oil, extraction method therefor and application thereof

An extraction method and a technology of bitter melon seeds, which are applied in the field of bitter melon seed oil and its extraction, can solve the problems of increasing production process equipment, personnel, and time requirements, low utilization rate of active ingredients of bitter melon seeds, cumbersome extraction process, etc., to achieve beneficial The maximum efficiency of ingredients, the extraction method is simple and easy, and the effect of increasing the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

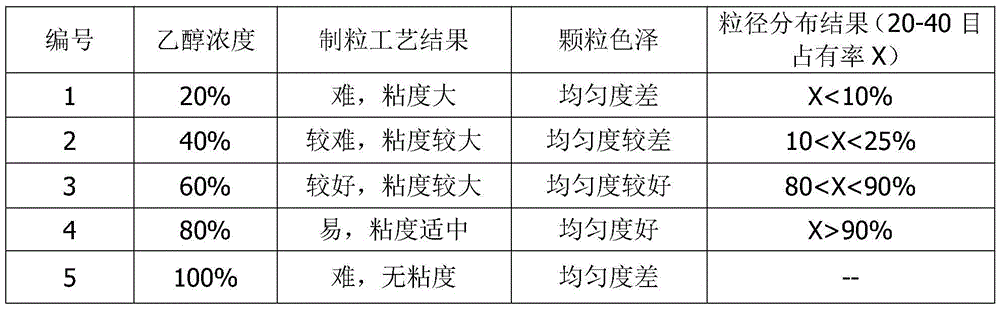

[0034] Weigh the dried bitter melon seeds, crush them through a 100-mesh sieve, granulate them with 60% ethanol aqueous solution, pass through a 20-mesh sieve and put them into an extraction kettle. The extraction conditions are: 22MPa, 35°C, static extraction for 10 minutes, dynamic extraction for 80 minutes, CO 2 The flow rate is 1.0L / min, and the mass volume ratio of material to entrainer is 1:0.5 (w / v). The two-stage separation process is: the first-stage separation pressure is 26MPa, the separation temperature is 20°C, the second-stage separation pressure is 9MPa, and the separation temperature is 30°C. The bitter gourd seed oil separated from the separation tank is collected, which is the target product.

Embodiment 2

[0036] Weigh the dried bitter gourd seeds, crush them through a 90-mesh sieve, granulate them with 75% ethanol aqueous solution, pass through a 40-mesh sieve and put them into the extraction kettle. The extraction conditions are: 26MPa, 33°C, static extraction for 30 minutes, dynamic extraction for 60 minutes, CO2 flow The mass volume ratio of material to entrainer is 1:0.6 (w / v). The two-stage separation process is: the first-stage separation pressure is 28MPa, the separation temperature is 25°C, the second-stage separation pressure is 12MPa, and the separation temperature is 35°C. The bitter gourd seed oil separated from the separation tank is collected, which is the target product.

Embodiment 3

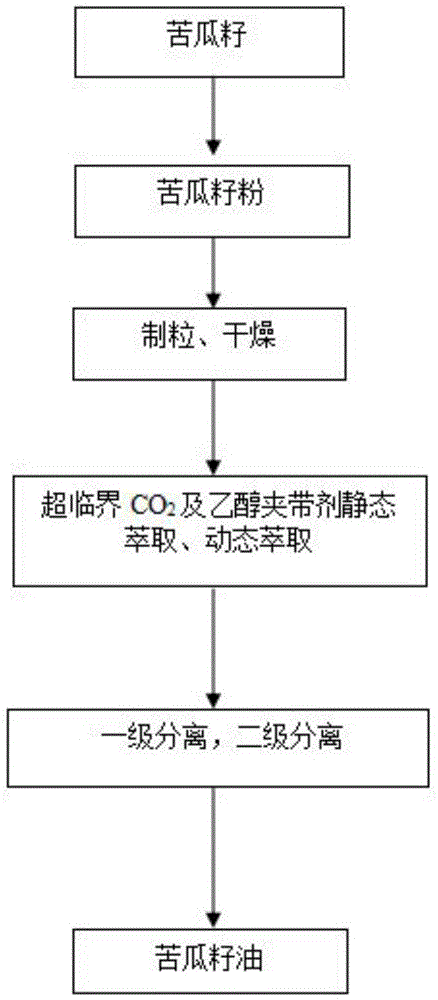

[0038] like figure 1 As shown, the dried bitter melon seeds were weighed, crushed through a 100-mesh sieve, granulated with 80% ethanol aqueous solution, passed through a 40-mesh sieve, and put into the extraction kettle. The extraction conditions were: 30MPa, 32°C, static extraction for 30min, dynamic extraction for 80min, CO2 The flow rate is 1.5 / min, and the mass volume ratio of material to entrainer is 1:0.8 (w / v). The two-stage separation process is: the first-stage separation pressure is 30MPa, the separation temperature is 30°C, the second-stage separation pressure is 14MPa, and the separation temperature is 35°C. The bitter gourd seed oil separated from the separation tank is collected, which is the target product.

[0039] The balsam pear seed oil obtained by the invention is not only easy to be absorbed by human body, but also has higher and wider application value because it is rich in various active ingredients except volatile oil. A kind of production method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com