Preparation method and application of modified natural bamboo fiber materials

A technology of raw bamboo fibers and raw fibers, which is applied in the field of preparation of modified bamboo raw fiber materials, can solve the problems that the modified properties of bamboo raw fibers have not been reported, and achieve the effects of rich raw materials, environmental friendliness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

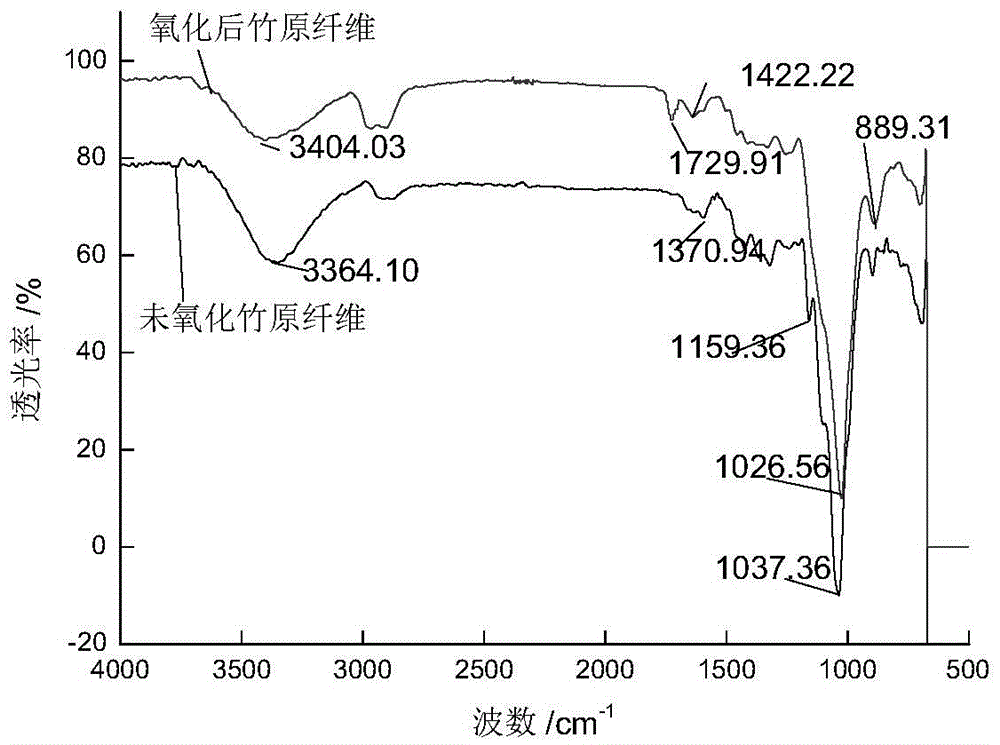

[0029] Embodiment 1 bamboo fiber pretreatment

[0030] Take 4g bamboo fiber and place it in 100g mass fraction of 15% sodium hydroxide solution, ultrasonically treat it for 30min, wash to neutral and dry to constant weight in a 50°C oven, when the concentration of sodium periodate is 20g / L, The reaction temperature was 40° C., and the reaction was carried out at pH 3 for 4 hours, and the content of aldehyde group was determined to be 1.67 mmol / g.

Embodiment 2

[0031] Embodiment 2 bamboo fiber pretreatment.

[0032] This example is basically the same as Example 1, except that the mass fraction of sodium hydroxide solution is 20%, the ultrasonic time is 40min, the oxidation reaction conditions are the same, and the measured aldehyde content is 1.90mmol / g.

Embodiment 3

[0033] Embodiment 3 bamboo fiber pretreatment.

[0034] This example is basically the same as Example 1, except that the mass fraction of sodium hydroxide solution is 25%, the oxidation reaction conditions are the same, and the measured aldehyde content is 2.10 mmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com