Concrete post-cast strip air mold

A post-casting strip and concrete technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve problems such as difficult handling, easy to break, increase labor intensity of construction workers, etc., to achieve Reduce working intensity and facilitate disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

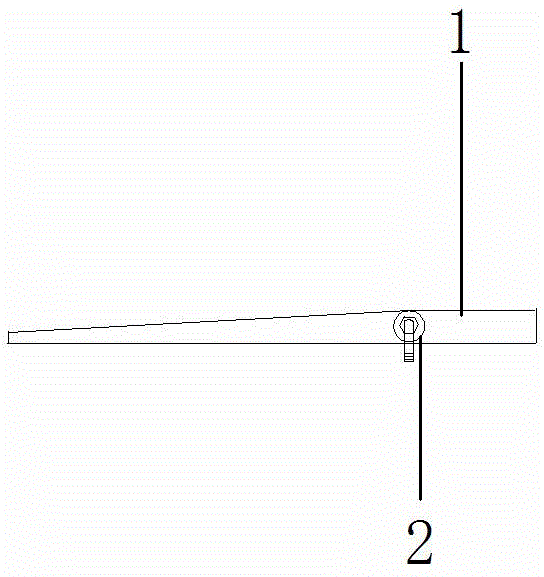

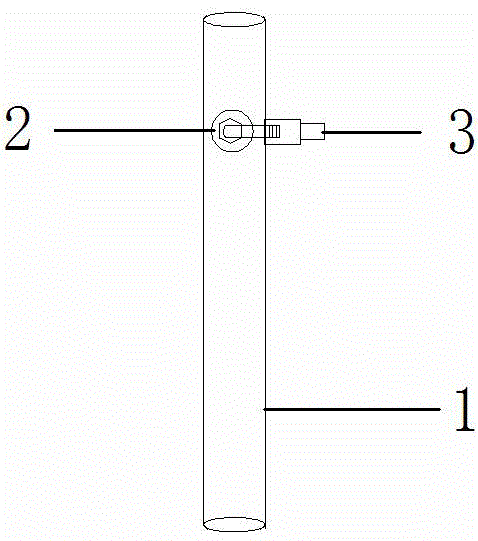

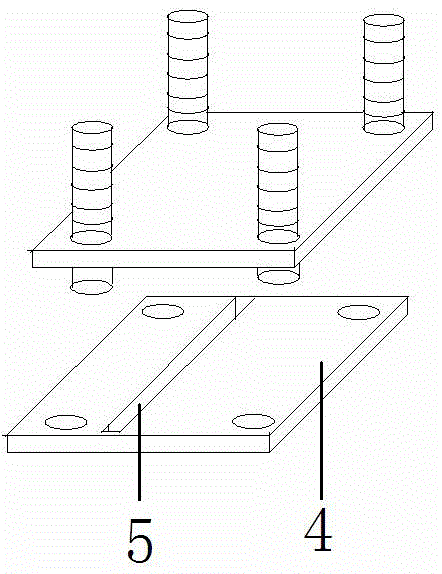

[0019] The present invention will be further described below in conjunction with accompanying drawings and examples of implementation. This embodiment includes an air mold 1, and the material of the air mold 1 is thermoplastic soft plastic or rubber. The material of the air mold 1 is preferably CPVC, PVC, neoprene, PP, PE, polypropylene plastic, polybutene plastic, and the air mold 1 is formed by sealing the side of a thermoplastic soft plastic or a rubber sheet through structural glue. Both ends of the air mold 1 are sealed, and the air mold 1 is provided with an air valve 2 for charging and deflated in the air mold 1 . After inflation, the air mold 1 is a cylindrical structure. The bottom of the air mold 1 is circular or oval. The air valve 2 is connected with a quick connector 3, which is convenient for inflation and deflation. The concrete post-casting belt air mold forms a mold with certain strength, toughness and rigidity after inflating. After deflation, the volume b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com