Special energy saving and emission reduction device for gasoline engine

A gasoline engine, energy-saving and emission-reduction technology, applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as car engine damage, insufficient utilization, reduced engine combustion efficiency, and carbon deposits, so as to save fuel consumption and reduce Pollutants, the effect of reducing waste emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

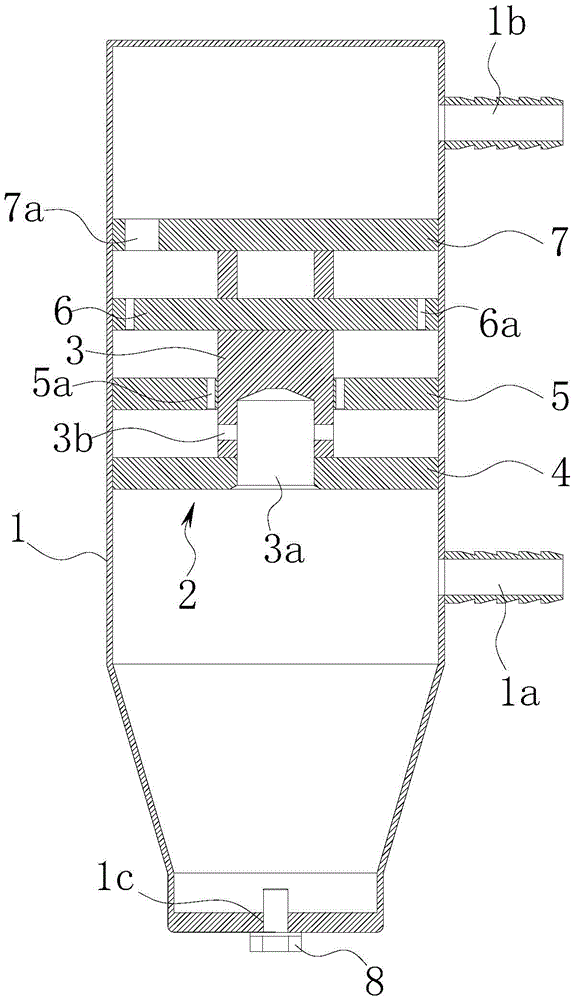

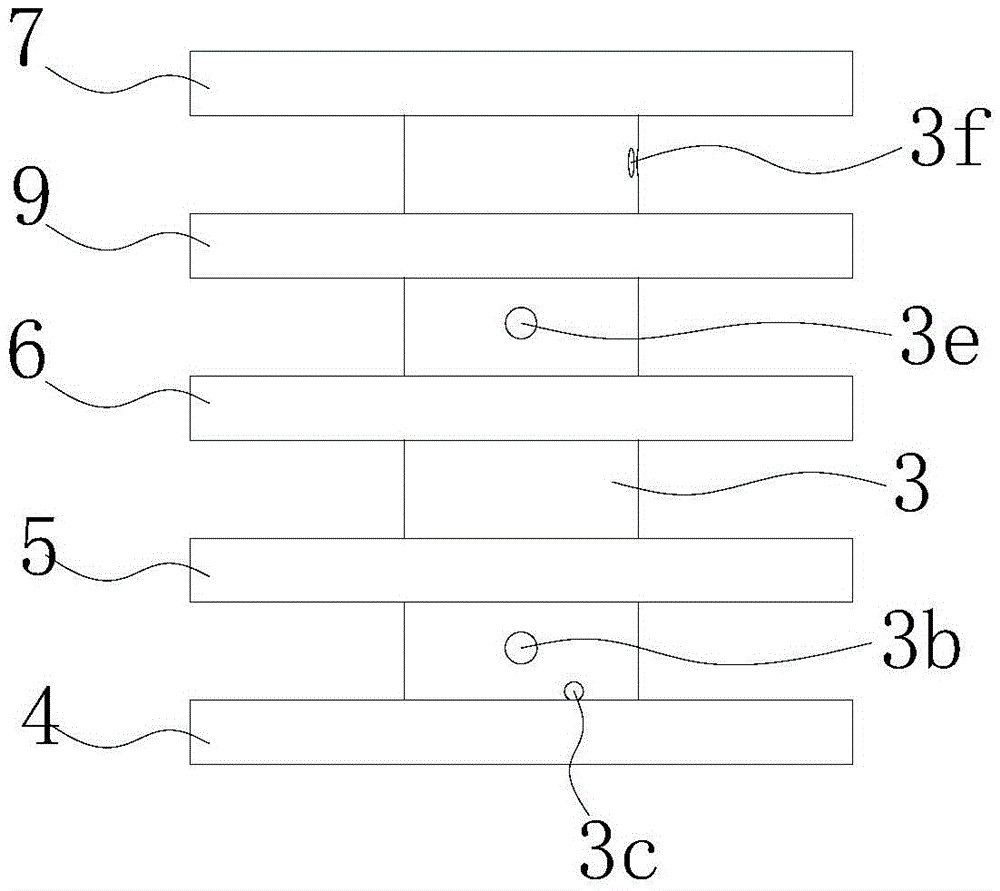

[0022] refer to figure 1 with figure 2 As shown, a special energy-saving and emission-reducing device for a gasoline engine of the present invention includes a sealed tank body 1, and an air inlet joint 1a and an air outlet joint 1a communicating with the inner cavity of the tank body 1 are arranged on the tank body 1 at intervals along the axial direction. Joint 1b, a filter element 2 is provided in the tank body 1 between the air inlet joint 1a and the air outlet joint 1b, and the filter element 2 includes a pillar 3 and a first partition 4 and a second diaphragm arranged on the outer wall of the pillar 3 along the circumferential direction. The partition 5, the third partition 6 and the fourth partition 7, the first, second, third and fourth partitions 4, 5, 6, 7 are arranged at intervals along the axial direction of the tank body 1 and divide the tank body 1 into several independent Each chamber has the same height along the axial direction of the tank body 1, and the he...

Embodiment 2

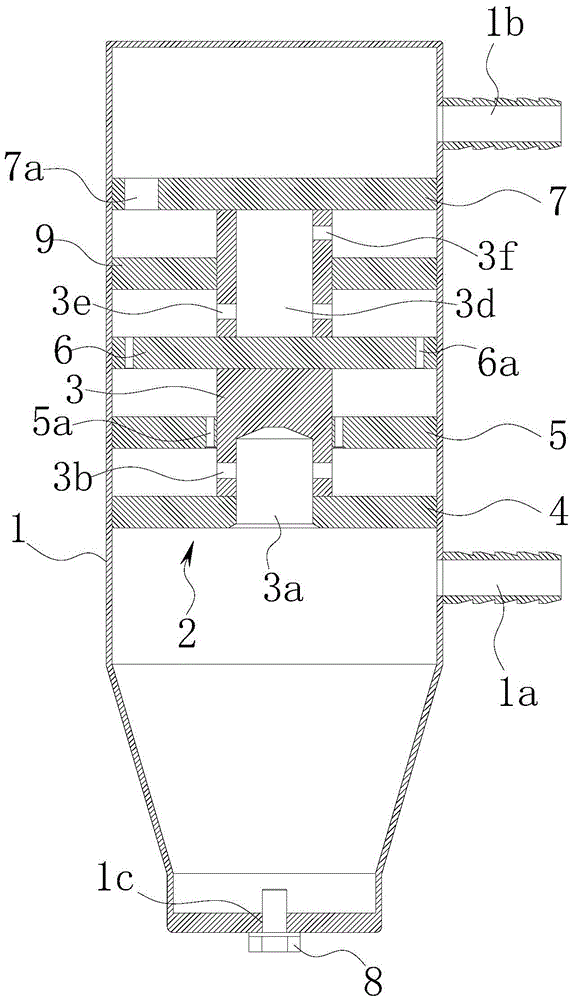

[0027] refer to image 3 As shown, a special energy-saving and emission-reducing device for a gasoline engine of the present invention has basically the same structure as that of Embodiment 1, except that a fifth partition is also provided between the third partition 6 and the fourth partition 7. plate 9, an air chamber 3d is provided in the pillar 3 between the third partition plate 6 and the fourth partition plate 7, and a gas chamber 3d is distributed along the circumferential direction on the pillar 3 between the third partition plate 6 and the fifth partition plate 9 A plurality of fourth through holes 3e, a plurality of fifth through holes 3f are provided on the outer wall of the column 3 between the fourth partition 7 and the fifth partition 9, and the fifth through holes 3f are located on the side away from the air outlet 7a. Preferably, the fifth through holes 3f are arranged radially. Meanwhile, the diameter of the fourth through hole 3e is 2.5-6mm, and the diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com