Chemical explosive loading low-temperature impact initiation experimental device and method

A low-temperature shock and experimental device technology, which is applied in the field of low-temperature shock initiation experiments loaded with chemical explosions and low-temperature shock initiation experimental devices loaded with chemical explosions, can solve the problems of sample temperature overshoot, prone to temperature gradients, and low temperature control accuracy, and achieve The effect of uniform temperature inside and outside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

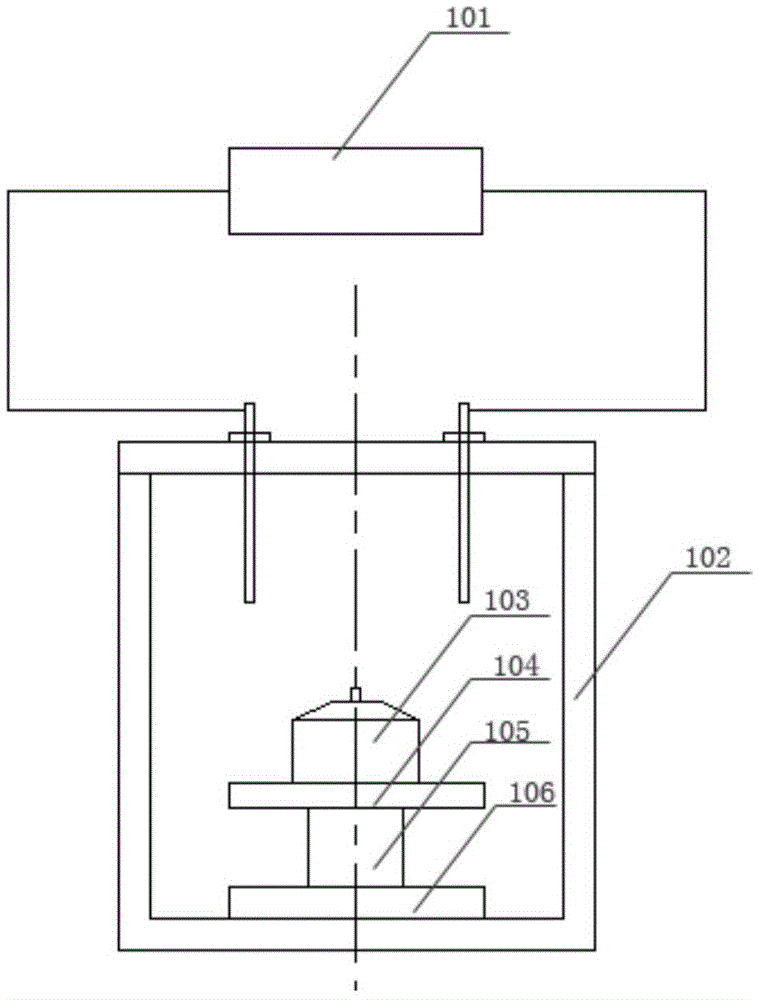

Image

Examples

Embodiment 1

[0038] This experiment needs to determine the impact initiation performance of B explosive under 3-4GPa pressure loading.

[0039]According to the purpose of the experiment, TNT explosive with a lower explosion pressure (about 20 GPa) was first selected as the booster. Then determine the material and thickness of the heat insulation layer and the attenuation layer. The heat insulation layer is a 10mm thick polytetrafluoroethylene layer, and the attenuation layer is a 18mm thick metal aluminum layer. After the shock wave is attenuated by the heat insulation layer and the attenuation layer, the pressure acting on the tested sample is 3-4GPa.

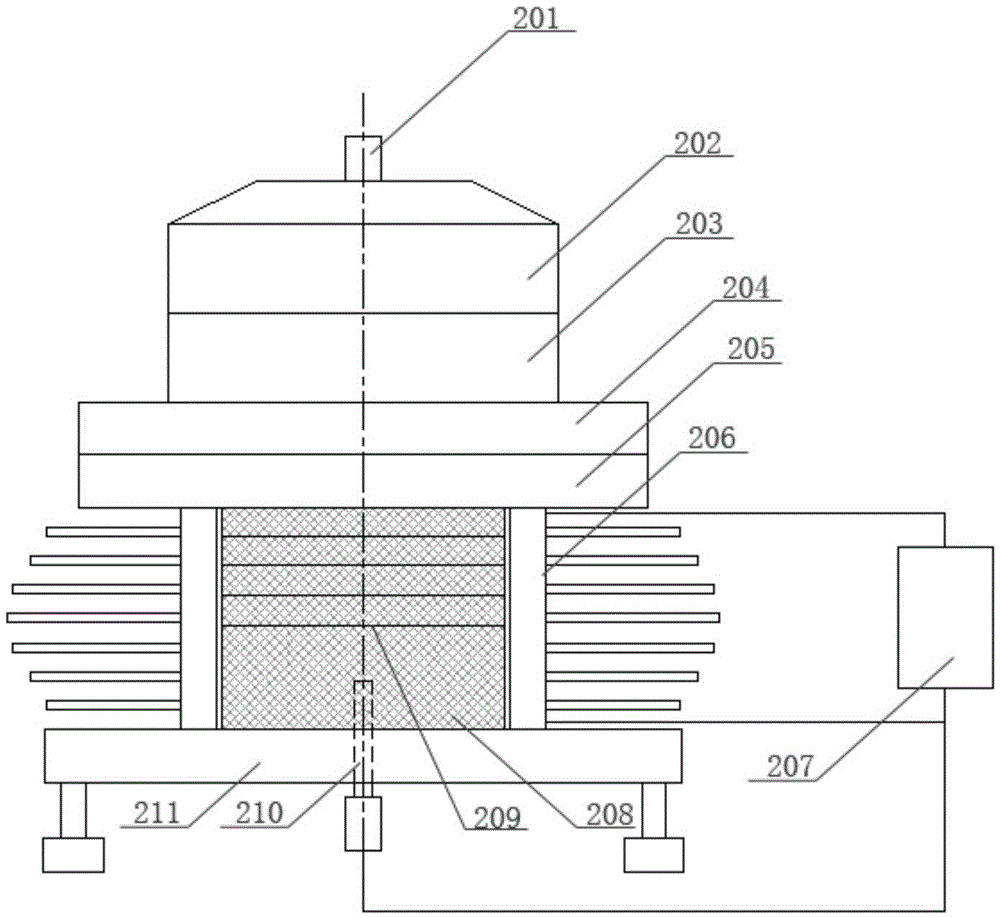

[0040] according to figure 2 The shown structure assembled the experimental setup.

[0041] In the low temperature control system, set the target temperature to -15°C, and the cooling rate to 3°C / min, and then start the cooling device to cool down the B explosive sample. The cooling device can be a Freon condenser. The cooling device d...

Embodiment 2

[0043] This experiment needs to measure the shock initiation performance of TATB explosive under 15-16GPa pressure loading.

[0044] According to the purpose of the experiment, PBX9404 explosive with a higher explosion pressure (about 36GPa) was first selected as the booster. Then determine the material and thickness of the heat insulation layer and the attenuation layer. The heat insulation layer is a 10mm thick polytetrafluoroethylene layer, and the attenuation layer is a 22mm thick metal aluminum layer. After the shock wave is attenuated by the heat insulation layer and the attenuation layer, the pressure acting on the tested sample is 15-16GPa.

[0045] according to figure 2 The shown structure assembled the experimental setup.

[0046] In the low temperature control system, set the target temperature to 0°C, and the cooling rate to 2°C / min, and then start the cooling device to cool down the TATB explosive sample. The cooling device can be an air-cooled condenser. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com