Simulation and evaluation system for low-salinity water injection experiment and method

A technology of experimental simulation and evaluation system, applied in the direction of material inspection products, soil material testing, etc., can solve problems such as weak persuasion, incompleteness, difficulty, etc., and achieve the effect of improving accuracy and comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

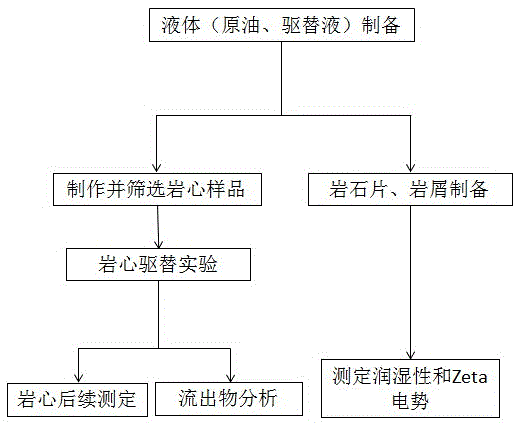

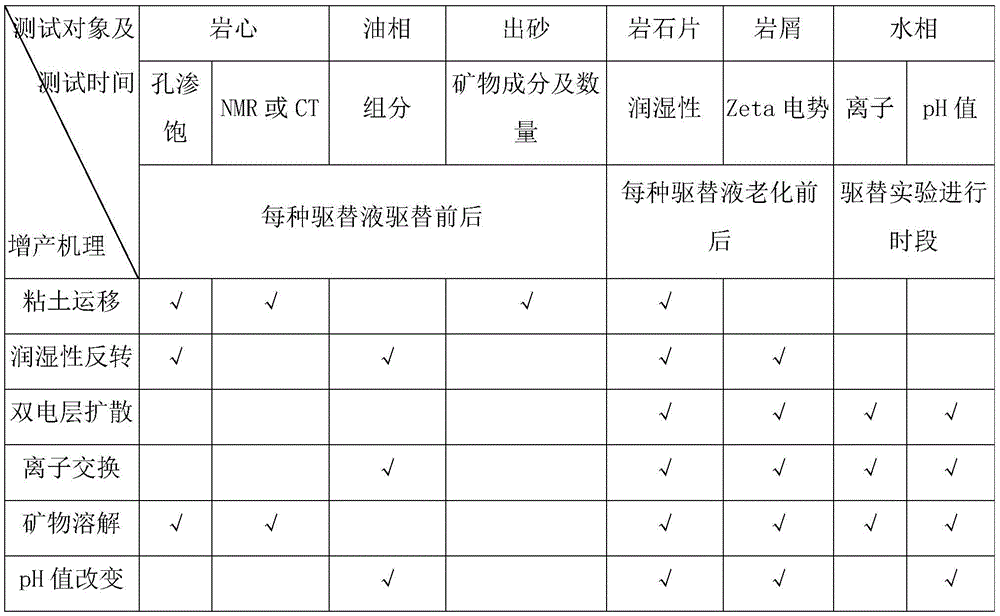

[0051] This embodiment is an illustration of the simulated low-salinity water injection process and evaluation method. figure 1 The steps that described method comprises are shown, and table 1 has shown the relation of various mechanisms of described method research and test object and test time:

[0052] (1) Preparation of water and crude oil: Prepare water with different salinities according to the actual raw water salinity and ion composition, respectively, raw water, salinity is 0.5 times, 0.2 times, 0.1 times, 0.05 times, 0.02 times of raw water times and 0.01 times the low salinity water; take back the crude oil from the site, and remove the solid impurities in it.

[0053] (2) Making and screening cores: After the rock samples were transported back from the site, several cores were drilled; the porosity, permeability, oil-water saturation, and pore throat physical properties of each core were tested and analyzed, and the physical properties of the pore throats were eval...

Embodiment 2

[0062] This embodiment is a description of the process and evaluation method of simulating the combination of low-salinity water injection and other three mining methods. figure 1 The steps that described method comprises are shown, and table 1 has shown the relation of various mechanisms of described method research and test object and test time:

[0063] (1) Preparation of water and crude oil: Prepare water with different salinities according to the actual raw water salinity and ion composition, respectively, raw water, salinity is 0.5 times, 0.2 times, 0.1 times, 0.05 times, 0.02 times of raw water times and 0.01 times the low salinity water; take back the crude oil from the site, and remove the solid impurities in it.

[0064] (2) Preparation of displacing solution: add three medicines to water to prepare a displacement solution with the same concentration of three medicines.

[0065] (3) Making and screening rock cores: After transporting the rock samples back from the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com