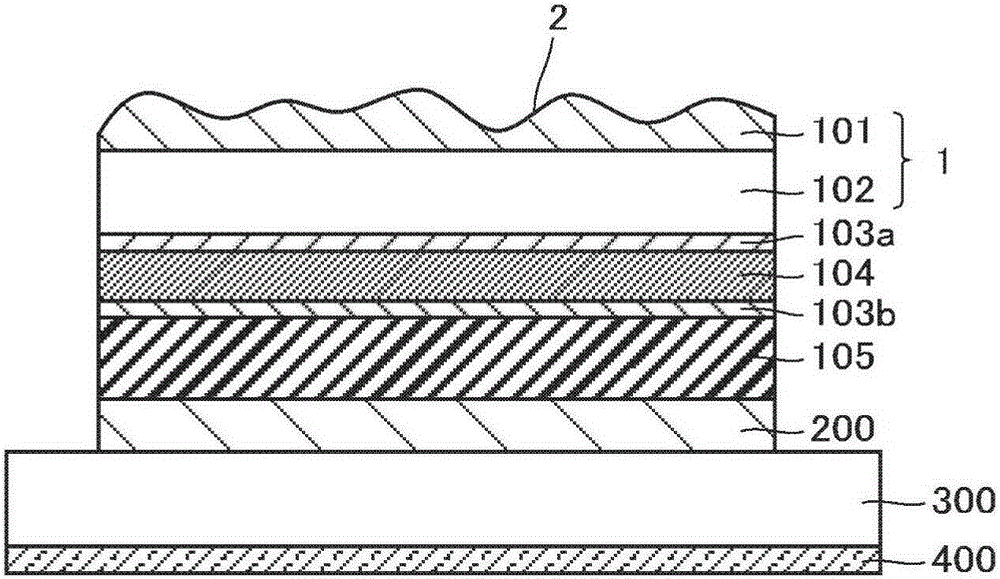

Antiglare film, antiglare polarizing plate, and image display device

An image display device, anti-glare film technology, applied in polarizing elements, nonlinear optics, optics, etc., can solve problems such as damage to visibility, and achieve the effects of low haze, sufficient anti-glare and glare suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

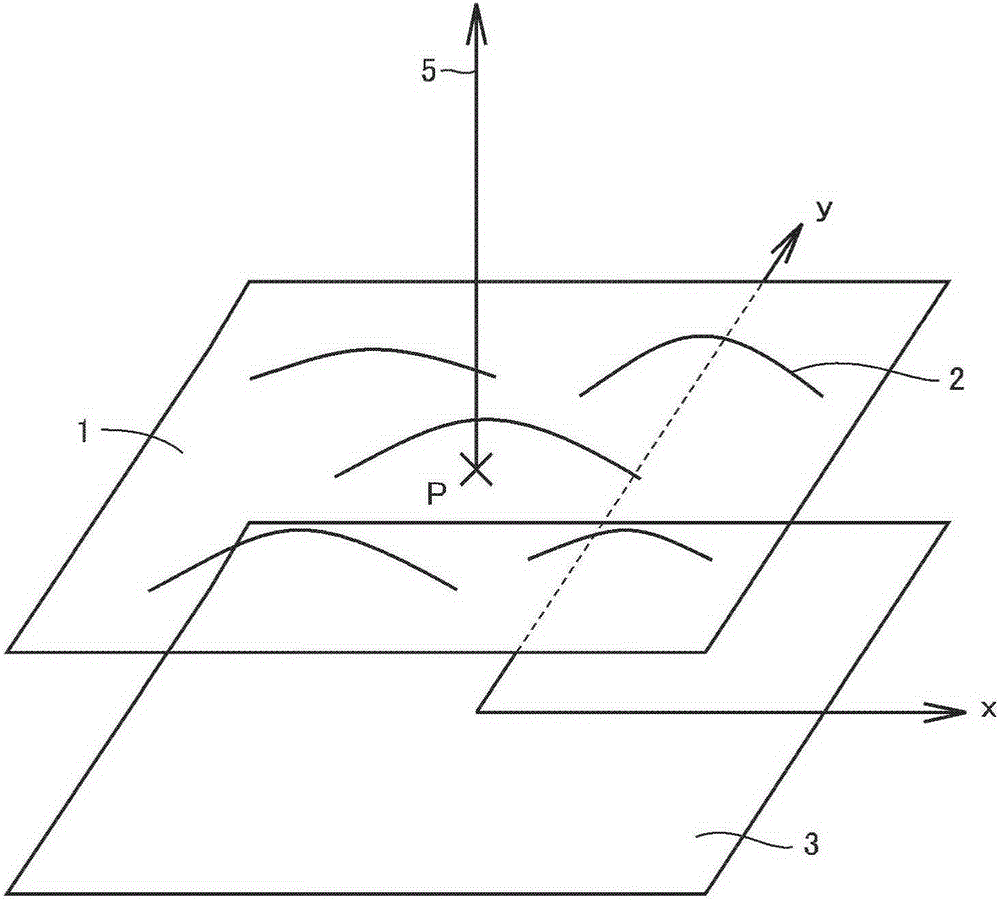

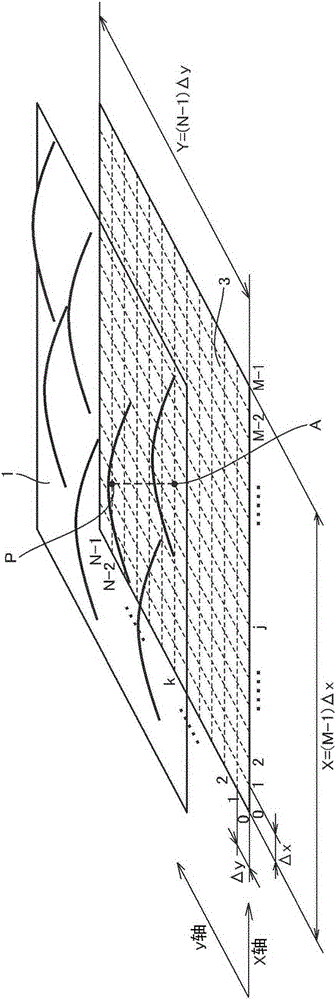

Method used

Image

Examples

Embodiment 1

[0199] (A) Preparation of polarizing film

[0200] A polyvinyl alcohol film with a thickness of 75 μm, a degree of polymerization of 2400, and a degree of saponification of 99.9% is stretched to a stretching ratio of 5 times in a dry uniaxial manner, and kept in a tense state, containing 0.05 parts by weight of iodine and 0.05 parts by weight of iodine in every 100 parts by weight of water. It was immersed in an aqueous solution of 5 parts by weight of potassium iodide at a temperature of 28° C. for 60 seconds. Next, while maintaining the state of tension, it was immersed at a temperature of 73° C. for 300 seconds in a boric acid aqueous solution containing 7.5 parts by weight of boric acid and 6 parts by weight of potassium iodide per 100 parts by weight of water. After talking, wash with pure water at 15° C. for 10 seconds. The water-washed film was kept under tension and dried at 70° C. for 300 seconds to obtain a polarizing film.

[0201] (B) Fabrication of a mold for fo...

Embodiment 2

[0217] Mold B was produced in the same manner as in Example 1 except that the first etching amount at the time of mold production was 5 μm, and the second etching amount was 13 μm. Moreover, except having used the mold B, it carried out similarly to Example 1, and produced the antiglare film B, the antiglare polarizing plate B, and the liquid crystal display device B. The uneven surface-color filter distance L was 523 μm.

Embodiment 3

[0219] Used in mold making Figure 9 The mold C was produced in the same manner as in Example 1 except that the first etching amount was set to 4.5 μm for the pattern [exposure pattern C] shown. Except having used the mold C, it carried out similarly to Example 1, and produced the antiglare film C, the antiglare polarizing plate C, and the liquid crystal display device C. The uneven surface-color filter distance L was 520 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com