Battery heating system

A battery heating system and heating system technology, which is applied to secondary batteries, battery pack components, circuits, etc., can solve the problems of reducing the effective proportion of energy used in battery pack cruising range, reducing pure electric driving range, and consuming battery system energy. , to achieve the effect of various line connection methods, various installation positions, and reducing temperature unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

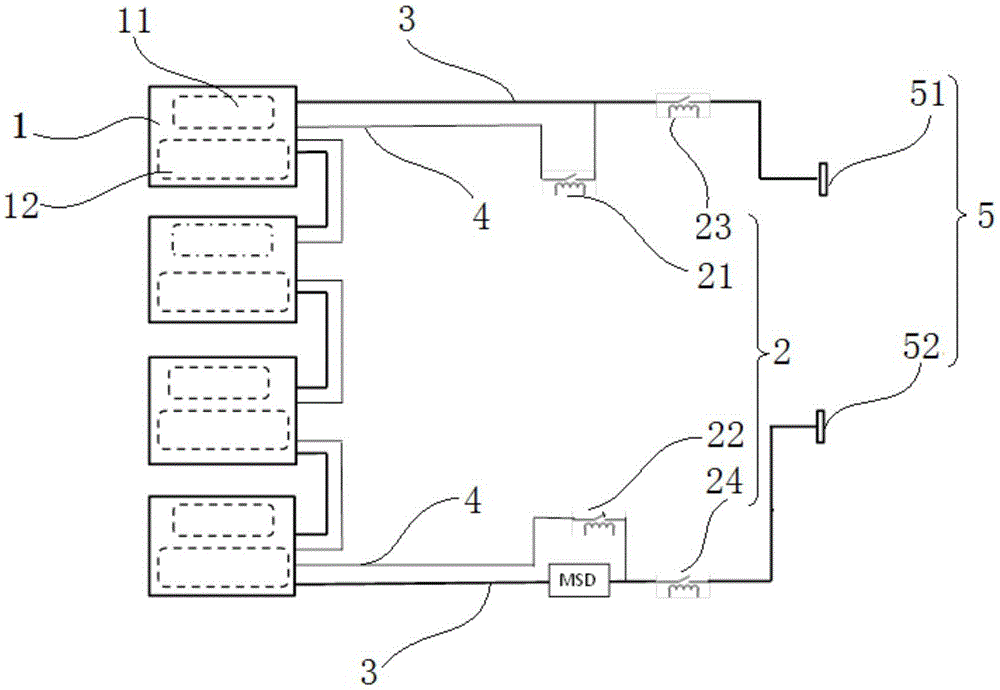

[0029] Below, will combine Figure 1 to Figure 7(a) ~(c) introduces the specific implementation manner of the battery heating system 100 of the present application.

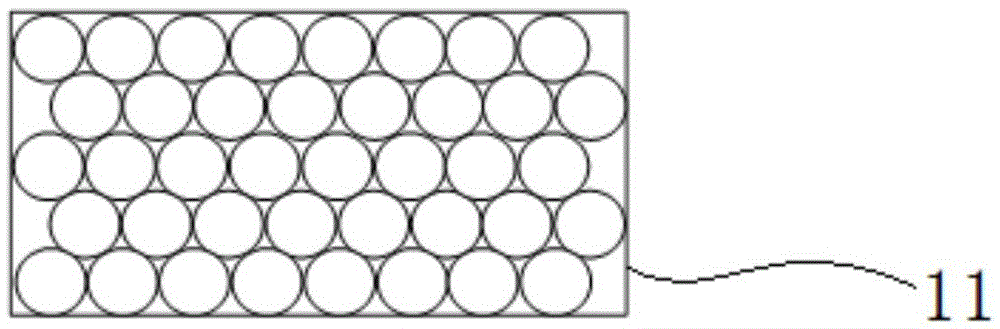

[0030] refer to figure 1 As shown, the battery heating system of this application is integrated by two subsystems, the heating system branch and the power battery system branch. The battery pack system branch includes a battery pack 1 and several relays 2. The battery pack 1 includes a plurality of battery modules 11 and a heating subsystem 12. The heating subsystem 12 includes a plurality of heaters 121. The heating system branch is connected to the battery pack. The system branches are connected in parallel, and the relay 2 is used to control the two branches, so that the power supply of the heating system can come from both the external charging pile and the power battery pack itself. Wherein, the relay 2 includes a heating positive relay 21, a heating negative relay 22, a main positive relay 23 and a main n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com