Built-in high-power-density permanent magnet motor integrated to 8AT transmission box

A high power density, permanent magnet motor technology, applied in the direction of magnetic circuits, electric components, electrical components, etc., can solve the problems of unable to meet the structural requirements of the gearbox, low torque density and power density, high vibration and noise of the motor, and achieve Significant magnetic concentration effect, low electromagnetic noise and high motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

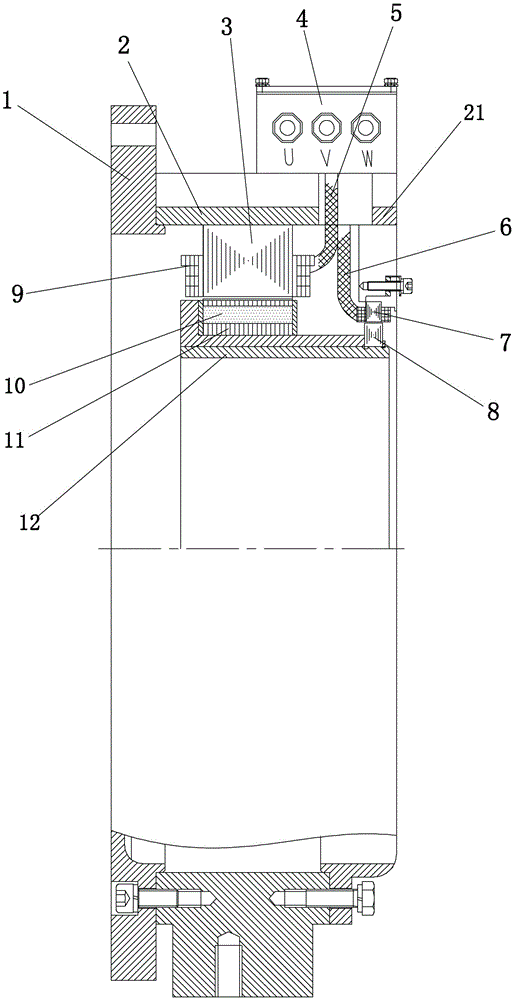

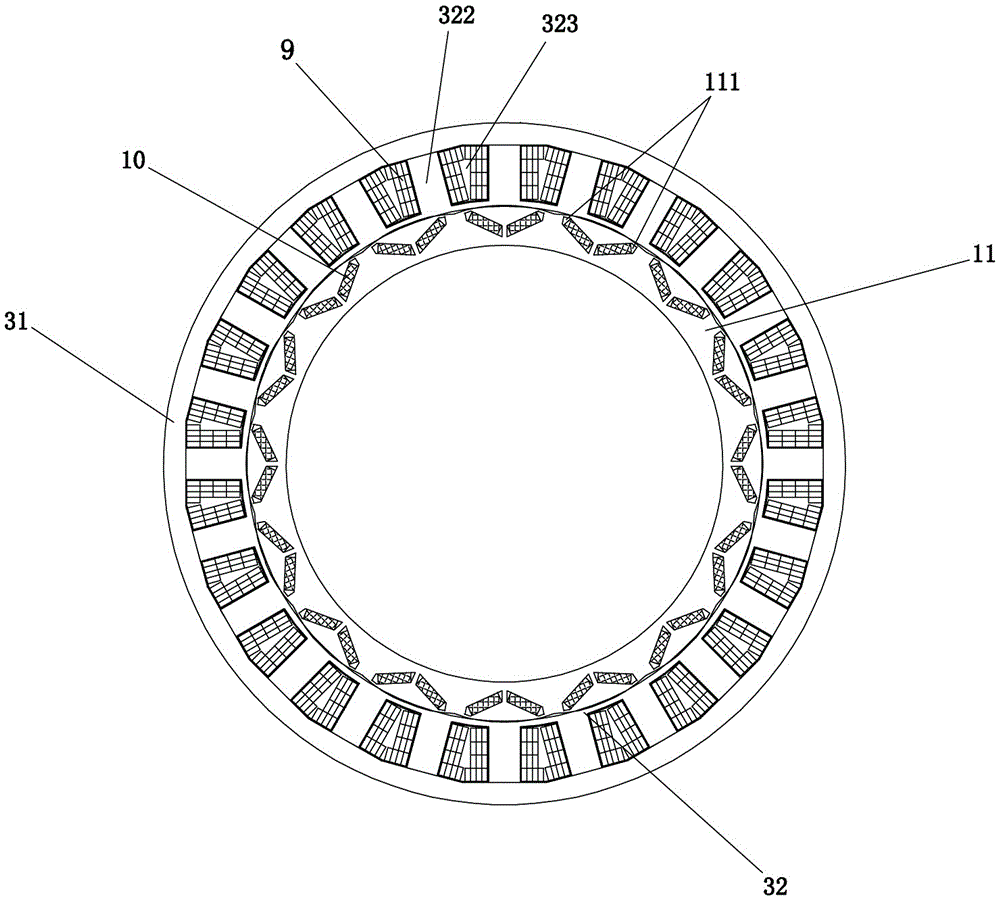

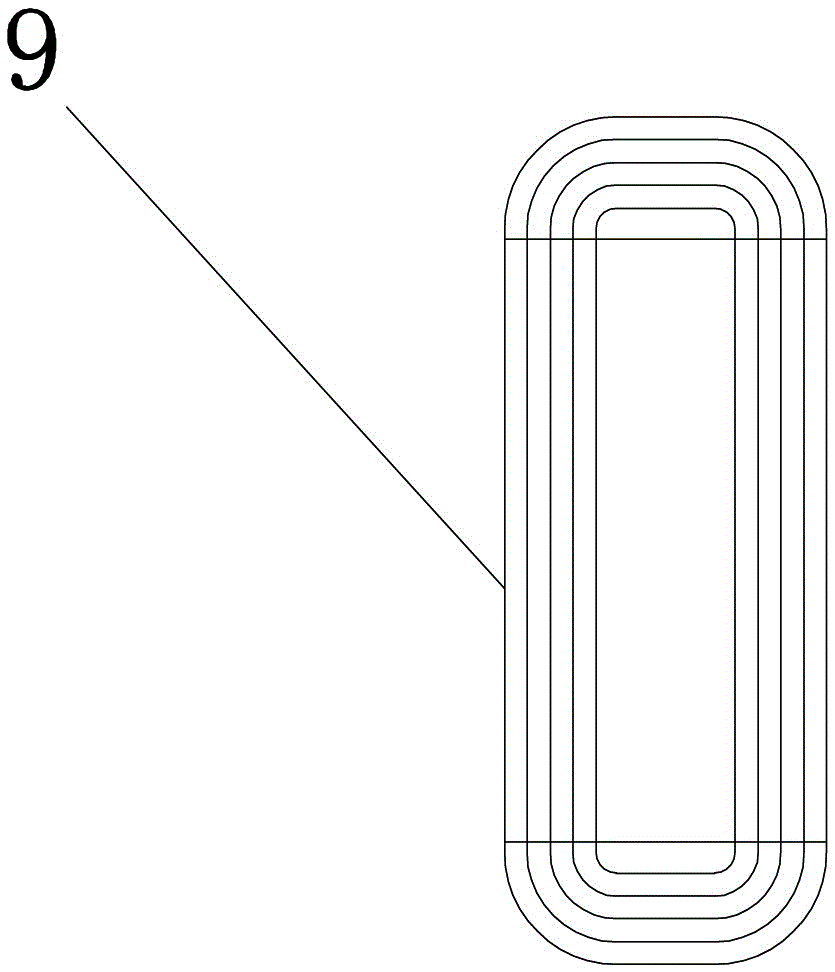

[0019] Such as Figure 1-Figure 8 As shown, a high power density permanent magnet motor integrated in an 8AT gearbox includes a gearbox flange 1, a gearbox housing 2, a built-in permanent magnet motor stator 3, a rotor 11, and a gearbox hub 12. The gearbox method The flange 1 is connected to the left end of the gearbox housing 2; the right end of the gearbox flange 1 is provided with a gearbox housing rear end cover 21; the built-in permanent magnet motor stator 3 is arranged on the inner wall of the gearbox housing 2; the built-in permanent magnet The motor stator 3 is provided with a flat wire forming winding 9; the rotor 11 is provided on the gearbox hub 12, and the rotor 11 is provided with a rotor magnet 10; the rotor 11 is located in the ring of the built-in permanent magnet motor stator 3; the flat wire forming winding 9 is connected with the outlet box 4 provided on the gearbox housing 2 through the lead-out cable 5; the gearbox hub 12 is provided with a resolver rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com