Electrically-driven pressure regulator- and volume-delivery unit

A pressure and volume technology, applied in the direction of brakes, transportation and packaging, machines/engines, etc., can solve the problems of low reliability, achieve the effect of small mass/inertia, and avoid throttling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

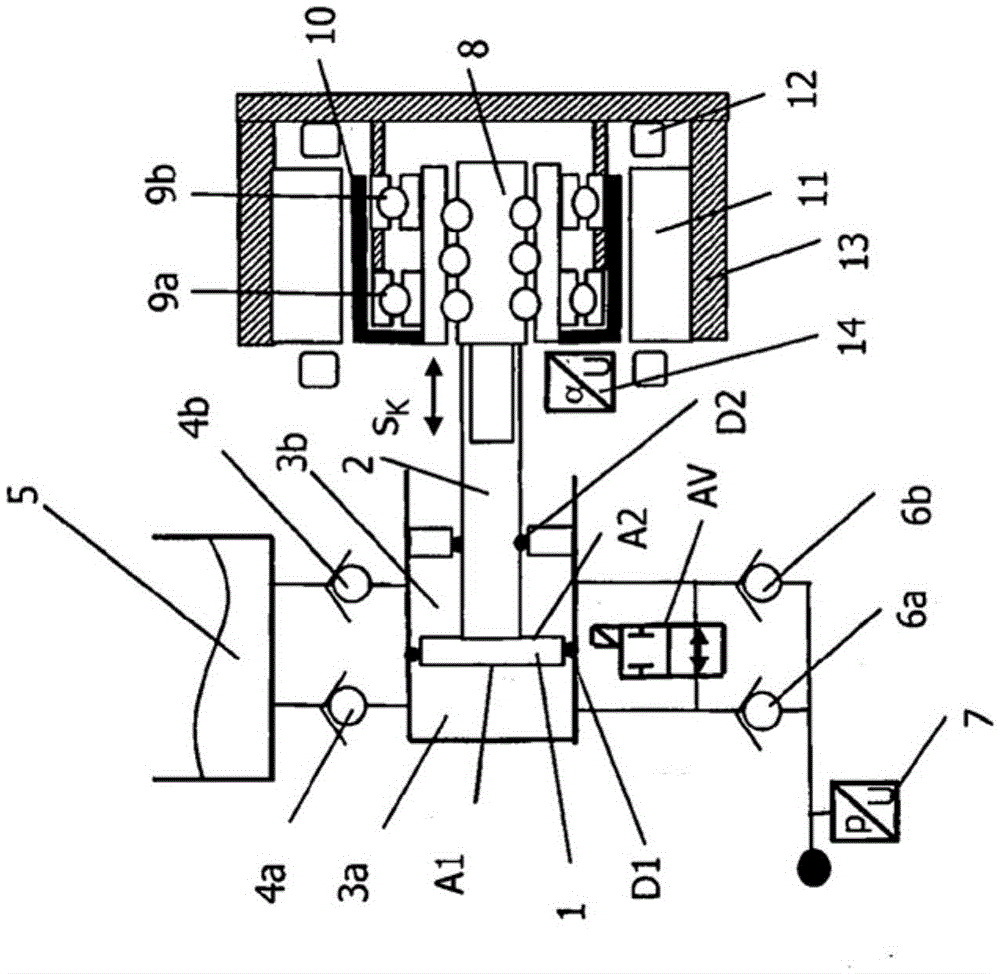

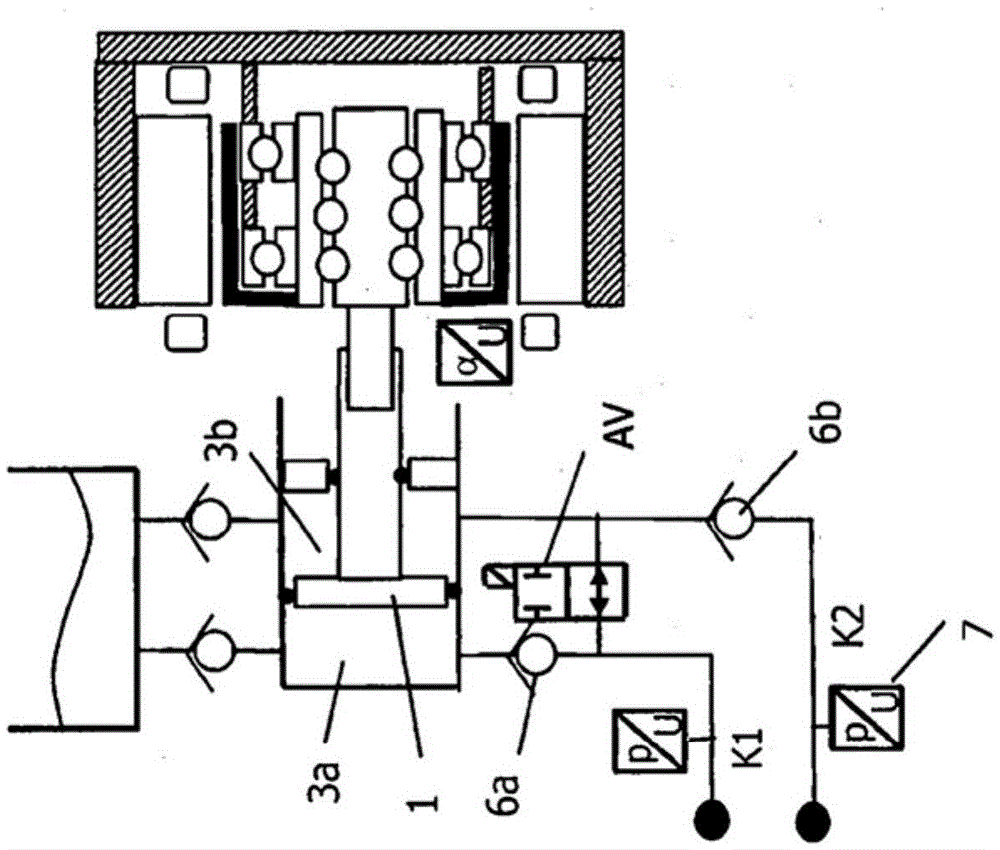

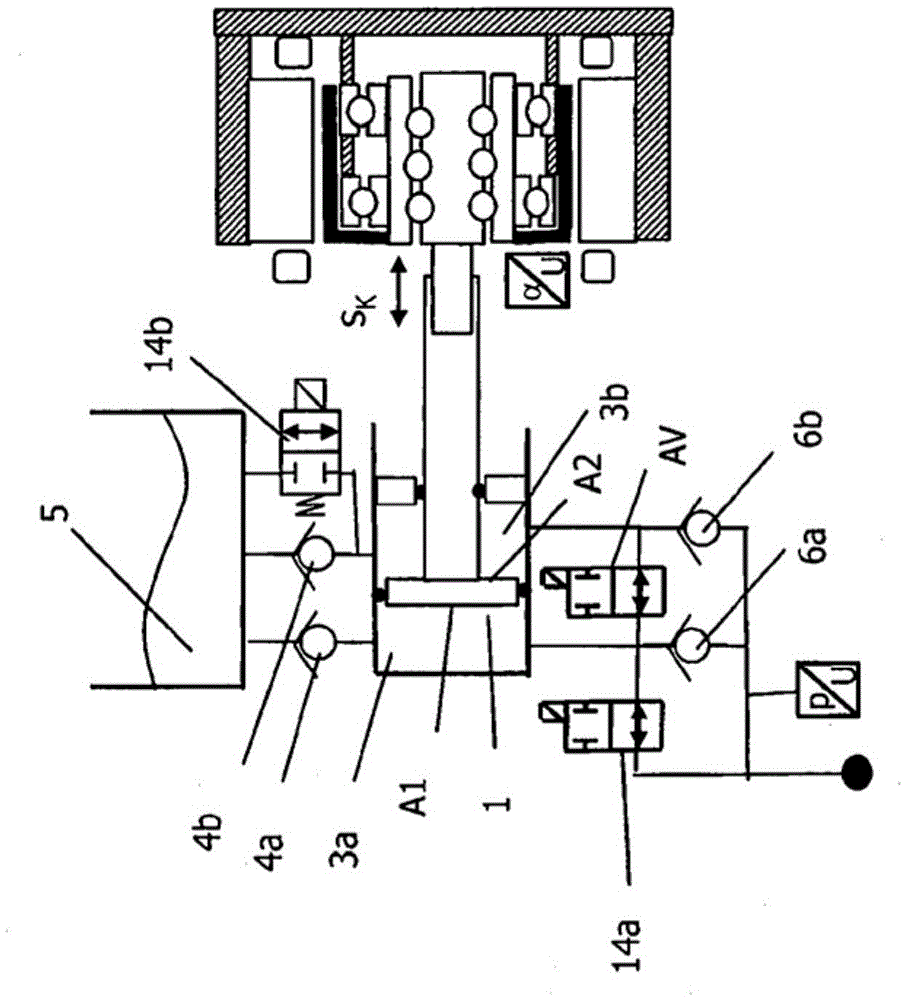

[0044] Figure 1a shows the basic structure of a pressure regulation and volume delivery unit (hereinafter also referred to as pressure regulation unit), which consists of a piston 1 acting on both sides (hereinafter also referred to as double-pass piston), Said piston is displaceable on the path sk in both directions via the plunger 2 . The double-stroke piston 1 delimits a first pressure chamber 3 a with an effective surface A1 and a second pressure chamber 3 b with an effective surface A2 . The ratio of the cross-sections of the faces A1 and A2 is approximately 2:1, at least 1.5:1 and at most 2.5:1. This ratio corresponds approximately to the ratio between the maximum pressure and the typical operating pressure. The two chambers 3a, 3b are connected to the storage container 5 via non-return valves 4a and 4b. The non-return valve has a large opening cross-section, whereby throttling effects are avoided. Additionally, a switchable pressure compensation valve AV is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com