Crude fiber formula feed for livestock and poultry

A formula feed and crude fiber technology, which is applied in animal feed, animal feed, animal husbandry, etc., can solve the problems of high proportion of grain raw materials, indigestion of poultry and livestock, and increased production costs, so as to achieve high digestibility and nutritional value, and reduce The effect of simple feed cost and ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] 30% of corn flour, 5% of bean flour, 5% of bone meal, 5% of the mixture of mulberry and tangerine peel according to the mass ratio of 1:1, 10% of the mixture of gramineous straw powder and Gentiana powder according to the mass ratio of 3:1, soybean 10% of the mixture of straw powder and amomum according to the mass ratio of 1:2, 20% of shell powder, 5% of oil residue, 5% of bamboo leaf powder, 3% of astragalus powder, and 2% of auxin.

Embodiment 2

[0014] 25% of corn flour, 8% of bean flour, 7% of bone meal, 5% of the mixture of mulberry and tangerine peel according to the mass ratio of 1:1, 10% of the mixture of gramineous straw powder and Gentiana powder according to the mass ratio of 3:1, soybean 11% of the mixture of straw powder and amomum according to the mass ratio of 1:2, 20% of shell powder, 5% of oil residue, 5% of bamboo leaf powder, 3% of astragalus powder and 1% of auxin.

Embodiment 3

[0016] 30% of corn flour, 10% of bean flour, 5% of bone meal, 5% of the mixture of mulberry and tangerine peel according to the mass ratio of 1:1, 10% of the mixture of gramineous straw powder and Gentiana powder according to the mass ratio of 3:1, soybean 10% of the mixture of straw powder and amomum according to the mass ratio of 1:2, 15% of shell powder, 5% of oil residue, 6% of bamboo leaf powder, 3% of astragalus powder, and 1% of auxin.

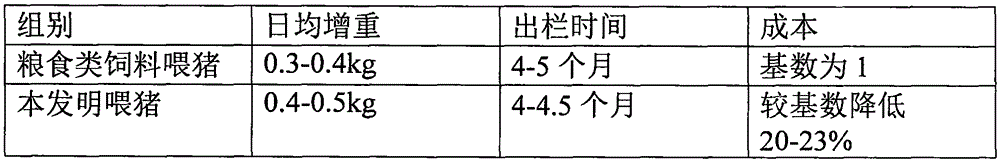

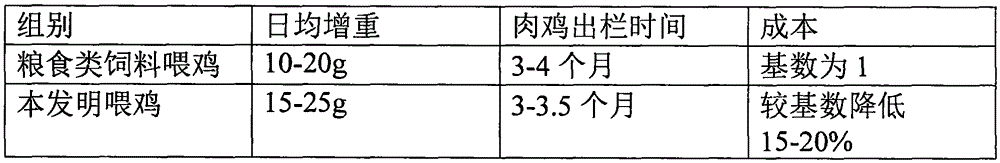

[0017] Select the present invention and traditional grain feed to feed pigs and chickens respectively and compare the following table

[0018] Table 1

[0019]

[0020] Table 2

[0021]

[0022] The invention has the advantages of simple proportioning and convenient use, and the total grain content is controlled at 45-55%, which greatly reduces feed cost. Because the feed increases the content of crude fiber, it is beneficial to the digestion and absorption of poultry and livestock, and reduces the grain raw materials without af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com