Novel adjustable grinding machine

An adjustable and new technology, applied in the direction of grinding machines, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of unfavorable long-term use of machinery, reduce the service life of grinding machines, increase production costs, etc., and achieve convenient position fixing and Workspace setting, flexible and convenient work, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the content, characteristics and effects of the present invention, the following examples are given in detail as follows:

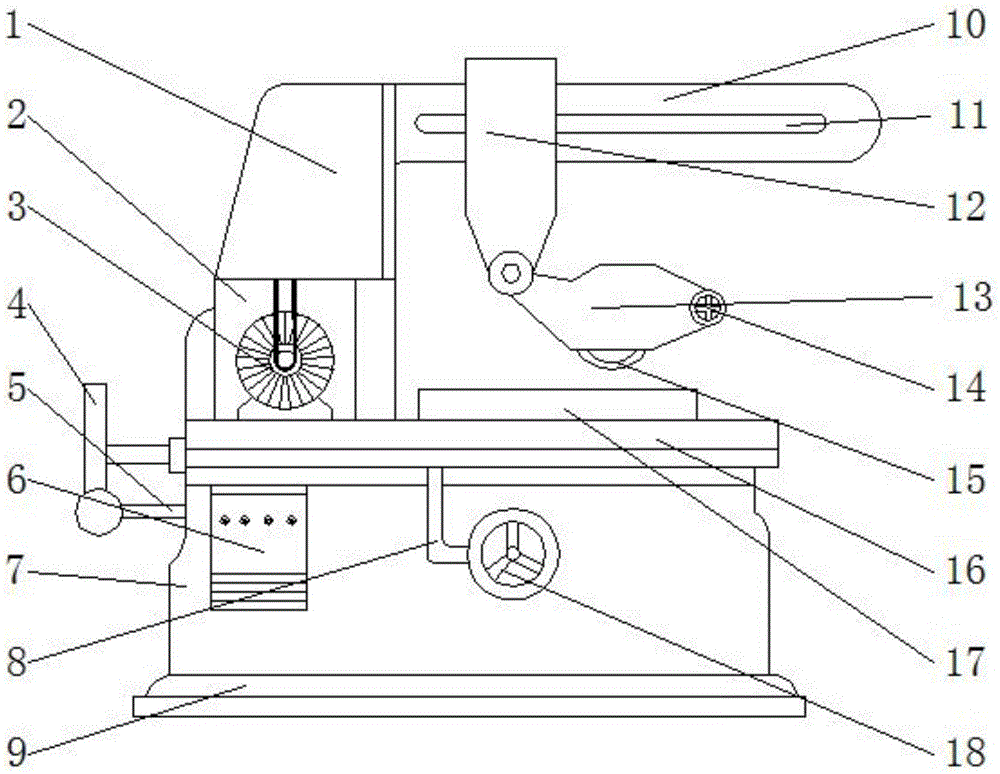

[0014] See figure 1 , the present invention includes a transmission center 1, a motor chamber 2, a motor 3, a handle 4, a push-pull rod 5, a control panel 6, a bed 7, a workbench upper and lower circulation device 8, a machine base 9, a fixed beam 10, a moving groove 11, Movers 12, grinding wheel device 13, hand control wheel 14, grinding wheel 15, workbench 16, electromagnetic sucker 17 and fixed wheel 18. in,

[0015] The transmission center 1 is respectively connected to the motor 3 and the mover 12 through a belt, and the transmission center 1 is located on the upper side of the motor 3, the engine room 2 is located on the lower side of the transmission center 1, the motor 3 is arranged inside the engine room 2, and the motor 3 is fixed on the bed 7, the handle 4 is connected to the push-pull rod 5, the push-pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com