Application of tailing machine-made sand winnowing powder in premixed concrete

A technology for ready-mixed concrete and concrete, which is applied in the field of new green environmental protection and energy-saving building materials, can solve the problems of unguaranteed quality, immature utilization technology, increased cost, etc., so as to save cement consumption, improve workability and reduce water consumption. heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

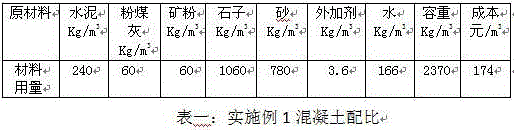

[0020] A kind of concrete, the ratio of raw materials per cubic concrete is as follows: cement: 240kg, fly ash: 60kg, slag powder: 60kg, stone powder: 40kg, gravel: 1060kg, sand: 780kg, admixture: 3.6kg and water: 166kg.

[0021]

[0022]

Embodiment 2

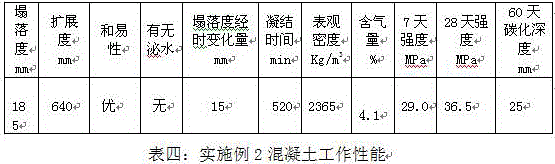

[0024] An application of tailings machine-made sand winnowing stone powder in ready-mixed concrete. The ratio of raw materials per cubic concrete is as follows: cement: 220kg, fly ash: 60kg, mineral powder: 60kg, stone powder: 20kg, gravel: 1060kg, sand: 780kg, admixture: 3.6kg and water: 166.

[0025]

[0026] Table three: embodiment 2 concrete ratio.

[0027]

Embodiment 3

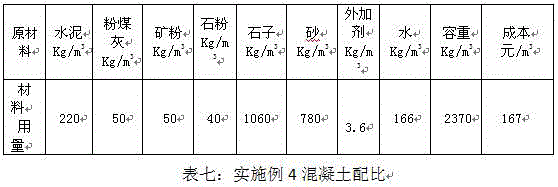

[0029] An application of tailings machine-made sand winnowing stone powder in ready-mixed concrete. The ratio of raw materials per cubic concrete is as follows: cement: 220kg, fly ash: 55kg, mineral powder: 55kg, stone powder: 30kg, gravel: 1060kg, sand: 780kg, admixture: 3.6kg and water: 166.

[0030]

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com