A method of preparing levulinates by utilizing furfuryl alcohol

A technology of levulinate and furfuryl alcohol, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of toxic organic solvents, easy to corrode, and difficult to recycle, and achieve good selectivity. Effects of less pollution and less reaction by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

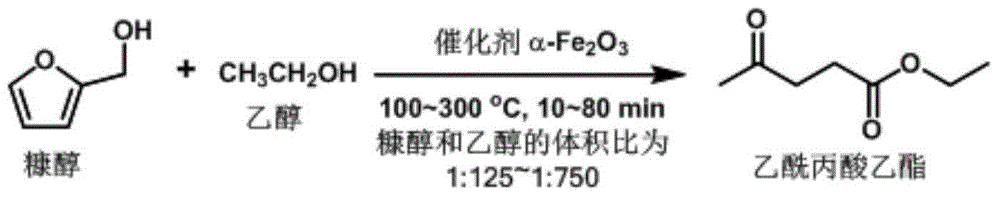

[0023] This embodiment relates to a metal oxide (α-Fe 2 o 3 ) convert furfuryl alcohol to prepare the method for ethyl levulinate, and the reaction equation is as follows:

[0024]

[0025] The method comprises the steps of:

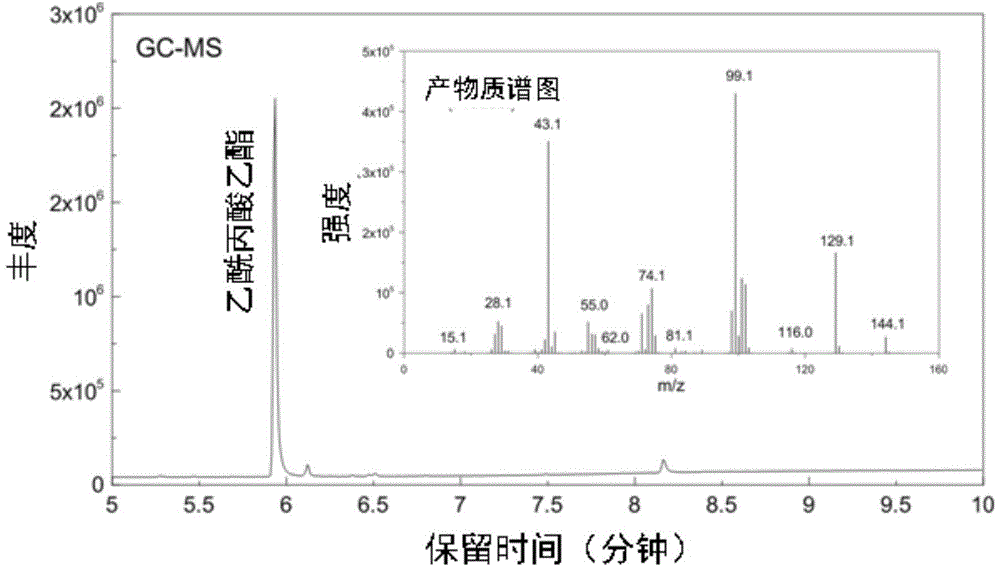

[0026] 0.23mmol furfuryl alcohol, 7.5mmol α-Fe 2 o 3 Mix powder and 10mL absolute ethanol evenly in a Teflon-lined high-pressure reactor. Fill the reactor with nitrogen to remove the air and seal the reactor to start the reaction. When the reaction temperature reaches 250°C, start timing and keep at 250°C for 60 minutes. , after the reaction is finished, cool at normal temperature, after the temperature of the reactor drops to normal temperature, the reaction mixture is filtered and the filtrate is collected, and ethyl levulinate is obtained through separation and purification, and GC-MS analysis shows that figure 1 As shown, the calculated ethyl levulinate yield reached 83%.

Embodiment 2

[0028] This embodiment relates to a metal oxide (α-Fe 2 o 3 ) convert furfuryl alcohol to prepare the method for methyl levulinate, comprising the steps:

[0029] 0.23mmol furfuryl alcohol, 12.5mmol α-Fe 2 o 3 Mix the powder and 7.5mL of anhydrous methanol evenly in a Teflon-lined high-pressure reactor, fill the reactor with nitrogen and remove the air, seal the reactor and start the reaction. When the reaction temperature reaches 250°C, start timing and keep the reaction at 250°C After 40 minutes, after the reaction was completed, it was cooled to normal temperature, and after the temperature of the reactor was lowered to normal temperature, the reaction mixture was filtered and the filtrate was collected, and ethyl levulinate was obtained through separation and purification. The yield of ethyl levulinate reached 73% according to gas chromatography analysis. The reaction equation is as follows:

[0030]

Embodiment 3

[0032] This embodiment relates to a metal oxide (α-Fe 2 o 3 ) convert furfuryl alcohol to prepare the method for n-butyl levulinate, and the reaction equation is as follows:

[0033]

[0034] The method comprises the steps of:

[0035] 0.23mmol furfuryl alcohol, 5mmolα-Fe 2 o 3 Mix powder and 7.5mL n-butanol evenly in a Teflon-lined high-pressure reactor. Fill the reactor with nitrogen to remove the air and seal the reactor to start the reaction. When the reaction temperature reaches 250°C, start timing and keep the temperature at 250°C. After 80 minutes, after the reaction was completed, it was cooled to normal temperature, and after the temperature of the reactor was lowered to normal temperature, the reaction mixture was filtered and the filtrate was collected, and ethyl levulinate was obtained through separation and purification. The yield of ethyl levulinate reached 86% according to gas chromatography analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com