Anti-water-lock workover fluid and preparation method

A technology of workover fluid and water-proof lock, which is applied in the directions of chemical instruments and methods, drilling compositions, etc., can solve the problem of low temperature resistance of water-proof lock and work-over fluid, and achieves good industrial application prospects and high production feasibility. , the effect of economic security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

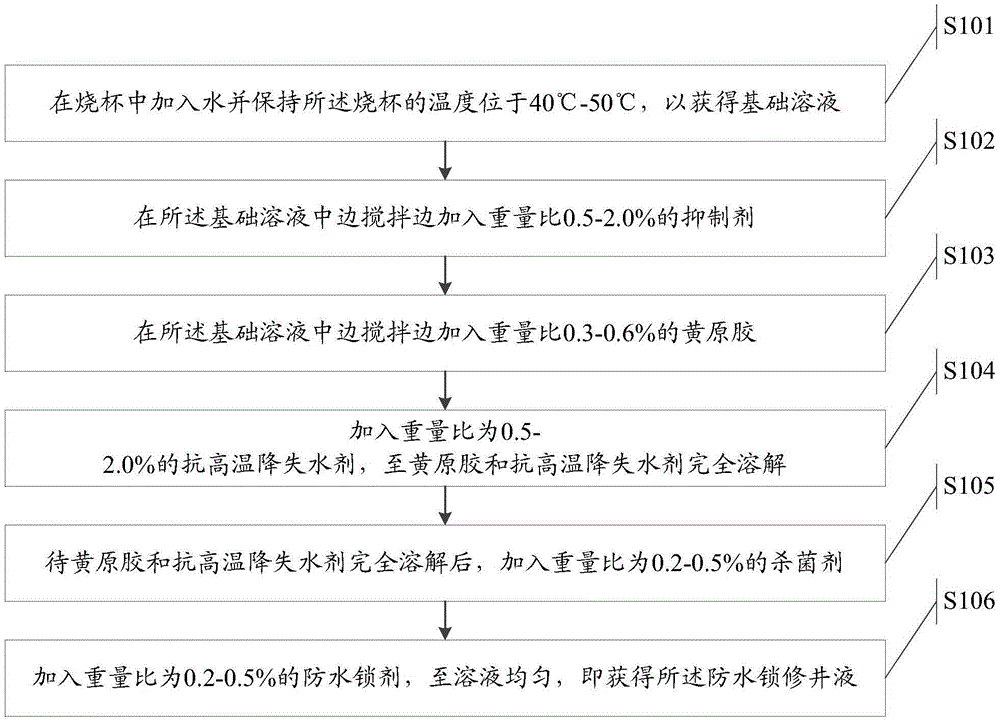

Method used

Image

Examples

Embodiment 1

[0066] First, in a 1000ml beaker, measure 320.3g of clear water, heat the temperature to 45°C, and keep the constant temperature, add 90g of potassium chloride and 76.7g of sodium formate, stir for 30min until completely dissolved, showing a uniform solution; then add 3g Xanthan gum, stir for 15 minutes, add 5g anti-high temperature fluid loss reducing agent and stir for 15 minutes until completely dissolved; finally add 2.5g fungicide and stir for 5 minutes, add 2.5g waterproof locking agent 3 and stir for 10 minutes, the waterproof lock workover can be prepared liquid.

Embodiment 2

[0068] First, in a 1000ml beaker, measure 374.25g of clear water, heat the temperature to 45°C, and keep the constant temperature, add 105.5g of potassium chloride and 10g of sodium formate, stir for 30min until completely dissolved and present a uniform solution; then add 2.25 g xanthan gum, stir for 18min, add 5g anti-high temperature dehydration agent and stir for 15min until completely dissolved; finally add 1.5g fungicide and stir for 5min, add 1.5g waterproof lock agent, stir for 10min, the waterproof lock repair can be prepared well fluid.

Embodiment 3

[0070] First, in a 1000ml beaker, measure 473.5g of clear water, heat the temperature to 45°C, and keep the constant temperature, add 10.0g of potassium chloride and 10g of sodium formate, stir for 30min until completely dissolved, showing a uniform solution; then add 1.5g Xanthan gum, stir for 20 minutes, add 2.5g anti-high temperature fluid loss agent and stir for 15 minutes until completely dissolved; finally add 1.0g fungicide and stir for 5 minutes, add 1.5g waterproof lock agent, stir for 10 minutes, and the waterproof lock repair can be prepared well fluid.

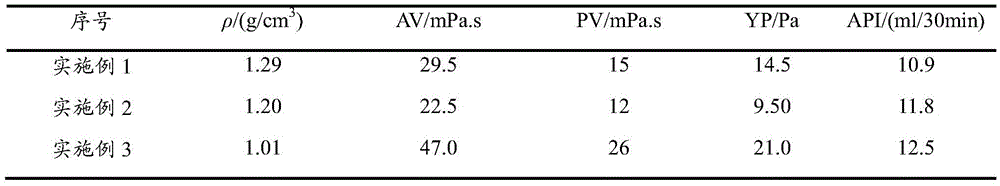

[0071] Table 1 is the rheology of the low permeability oilfield waterproof lock workover fluid of the present invention

[0072] Table 1 Basic performance evaluation of workover fluids

[0073]

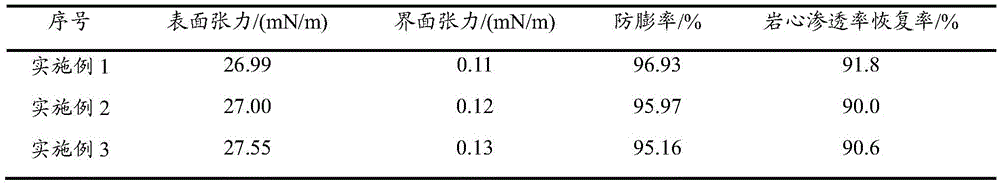

[0074] Table 2 is the evaluation result of the oil layer protection effect of the waterproof lock workover fluid in the low-permeability oil field of the present invention

[0075] Table 2 Evaluation of oil layer prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com