Hydraulic cold pressing method of fructus trichosanthis seed oil

A technology of hydraulic cold pressing and melon seed oil, applied in the direction of fat oil/fat production, fat production, etc., can solve problems such as inability to guarantee, relevant parameters are not formulated, and difficult to remove, etc., and achieve the effect of improving oil yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

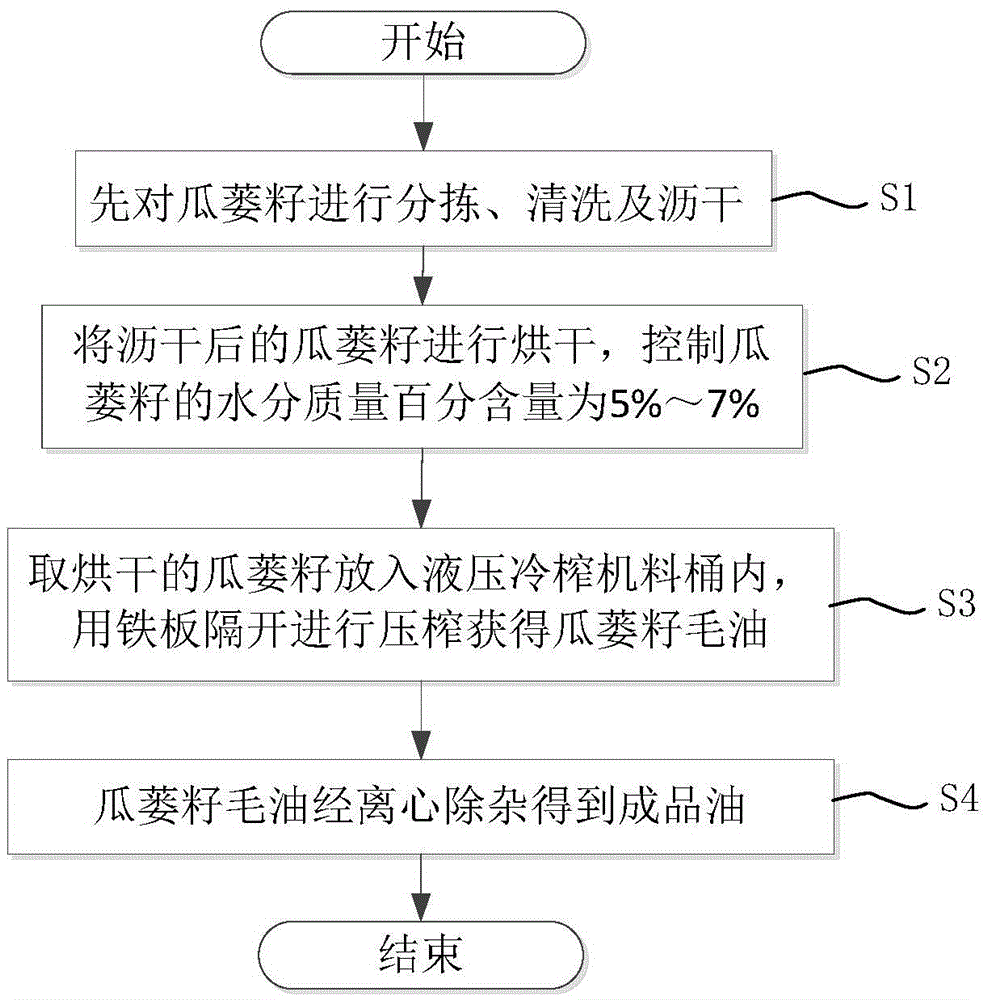

[0030] figure 1 It is a schematic flow chart of the hydraulic cold pressing of Trichosanthes seed oil of the present invention.

[0031] See figure 1 , the hydraulic cold pressing method of Trichosanthes quince seed oil provided by the invention, comprises the steps:

[0032] a) Sorting the Trichosanthes seeds first, then cleaning and draining;

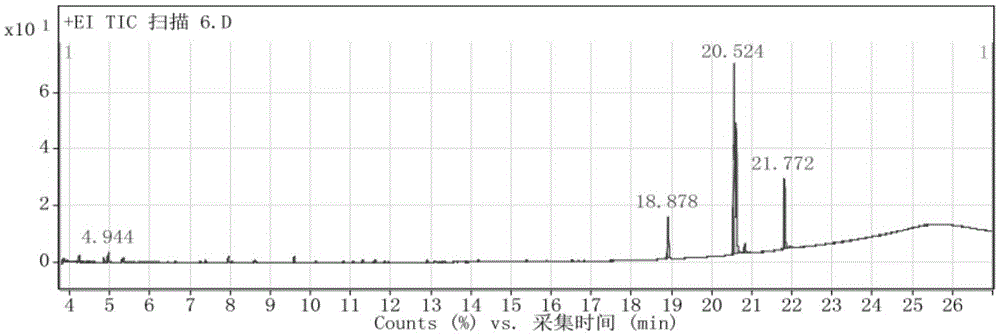

[0033] b) Dry the drained Trichosanthes seeds at a drying temperature of 50°C, control the moisture content of the Trichosanthes seeds to 5% to 7% according to the relationship between the drying time and the specific gravity of water loss, and dry at a temperature of 50°C For the relationship between drying time and water loss specific gravity, please refer to Figure 4 ;Preferably adopt a blower type drying oven, and dry at a temperature of 50°C until the moisture content is 6%;

[0034] c) Take the drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com