Smelting method of nickel-based high-temperature alloy

A technology of nickel-based superalloy and smelting method, applied in the field of alloy smelting, can solve the problems of difficulty in controlling the chemical composition of the alloy, affecting the comprehensive properties of the alloy, and excessively large amount of addition at one time, so as to improve the durability performance and room temperature tensile performance, guaranteeing Alloy properties, the effect of reducing segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

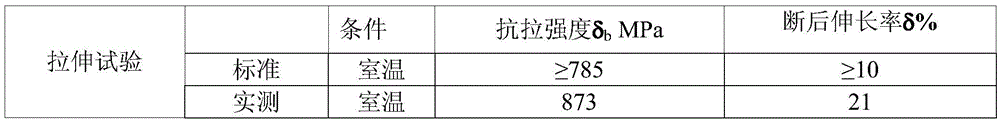

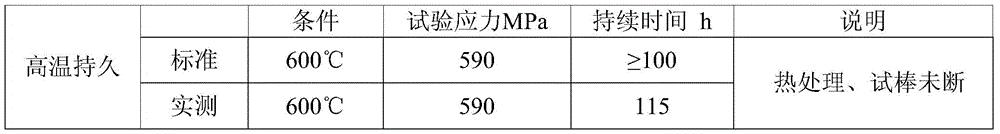

[0035] According to the standard of K414 alloy, it is produced by the smelting method of the present invention, its chemical composition is as shown in Table 1, and its performance parameters are as shown in Table 2.

[0036] Taking the 200Kg vacuum furnace as an example, the smelting method of the present invention is as follows:

[0037] (1) The first step of carbon deoxidation:

[0038] Graphite, which accounts for 50% of the total carbon content of the superalloy, is added to the vacuum furnace crucible, placed at the bottom of the crucible, and all elements in the superalloy except aluminum, titanium, boron, and nickel are added to the vacuum furnace crucible for smelting ; Graphite is particles crushed to 2-5mm by spectral graphite electrodes; smelting temperature is 1570±10°C, and smelting time is 25 minutes;

[0039] (2) The second step carbon deoxidation:

[0040] When the temperature rises to 1580±10°C, add the remaining graphite into the crucible, refine at 80KW f...

Embodiment 2

[0054]According to the standard of K414 alloy, it is produced by the smelting method of the present invention, its chemical composition is shown in Table 3, and its performance parameters are shown in Table 4.

[0055] Taking the 200Kg vacuum furnace as an example, the smelting method of the present invention is as follows:

[0056] (1) The first step of carbon deoxidation:

[0057] Graphite, which accounts for 50% of the total carbon content of the superalloy, is added to the vacuum furnace crucible, placed at the bottom of the crucible, and all elements in the superalloy except aluminum, titanium, boron, and nickel are added to the vacuum furnace crucible for smelting ; Graphite is particles crushed to 2-5 mm by spectral graphite electrodes; smelting temperature is 1590±10°C, and smelting time is 20 minutes;

[0058] (2) The second step carbon deoxidation:

[0059] When the temperature rises to 1590±10°C, add the remaining graphite into the crucible, refine at 80KW for 20m...

Embodiment 3

[0073] According to the standard of K414 alloy, it is produced by the smelting method of the present invention, its chemical composition is shown in Table 5, and its performance parameters are shown in Table 6.

[0074] Taking the 200Kg vacuum furnace as an example, the smelting method of the present invention is as follows:

[0075] (1) The first step of carbon deoxidation:

[0076] Graphite, which accounts for 50% of the total carbon content of the superalloy, is added to the vacuum furnace crucible, placed at the bottom of the crucible, and all elements in the superalloy except aluminum, titanium, boron, and nickel are added to the vacuum furnace crucible for smelting ; Graphite is particles crushed to 2-5 mm by spectral graphite electrodes; smelting temperature is 1580±10°C, and smelting time is 30 minutes;

[0077] (2) The second step carbon deoxidation:

[0078] When the temperature rises to 1570±10°C, add the remaining graphite into the crucible, refine at 80KW for 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com