Temporary reinforcement method for transverse partitioning construction of steel box girder bridge

A steel box girder, transverse technology, applied in the direction of bridges, bridge materials, bridge construction, etc., can solve the problems of reducing the service life and safety of bridges, and large residual stress at welding points, so as to reduce displacement difference and increase fatigue stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

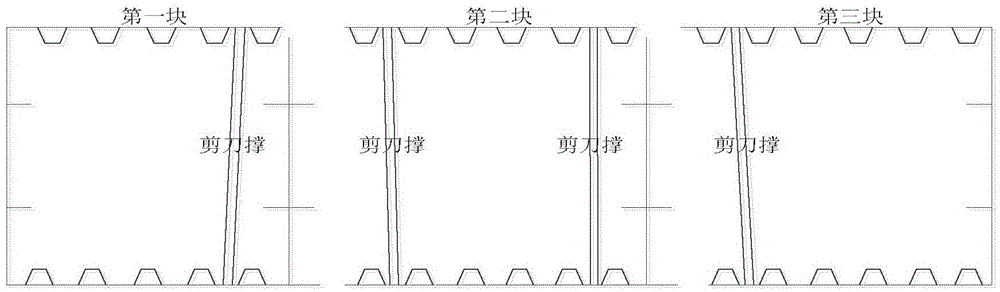

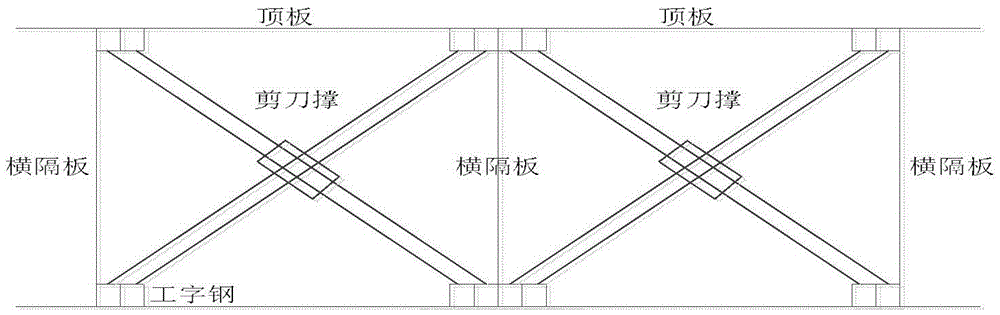

[0013] like figure 1 , figure 2 , image 3 As shown, a temporary reinforcement method for steel box girder transverse block construction, after the steel box girder is horizontal block, a scissor brace is set on both sides of the web of the beam block separated by a longitudinal rib, the web of the beam block is The beam block web at the division of the steel box girder; the fulcrum of the scissors is set at the junction of the diaphragm and the top and bottom plates, and the material used for the scissors is channel steel or I-beam; the intersection of the scissors is made of steel plates It is welded firmly; the split point of the top plate of the steel box girder and the split point of the bottom plate are misplaced; the split point of the top plate of the steel box girder and the split point of the bottom plate are respectively located on both sides of the web and the horizontal distance is not less than 400mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com