Rail snow remover

A technology for snow removal vehicles and tracks, which is applied in the field of track snow removal vehicles and snow removal vehicles for cleaning snow on the surface of railway tracks, can solve problems such as inapplicability, and achieve the effects of good effect, high efficiency and fast snow removal speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

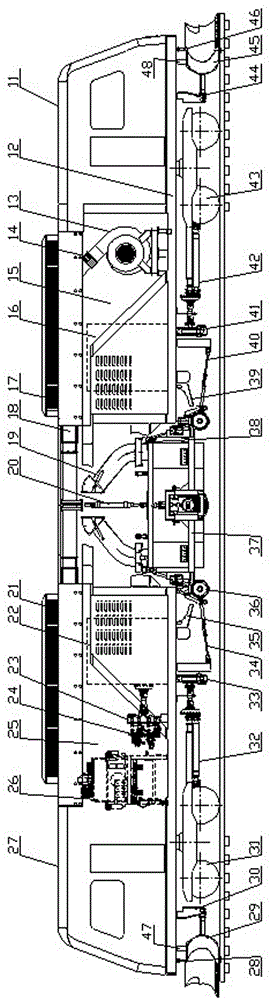

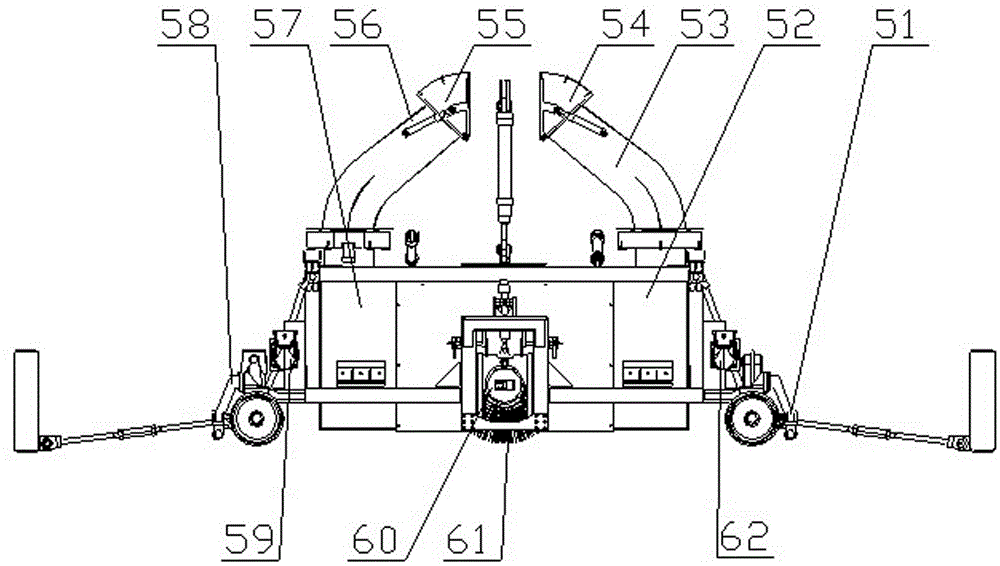

[0037] Example 1.1, the present embodiment provides a track snow removal vehicle, which includes a vehicle frame 12, which is symmetrical about its transverse central axis, and a brush-throwing snow removal device is installed in the middle of the vehicle frame 12, and the brush-throwing snow removal device is pulled by the right side. The rod 40 and the left drawbar 34 are respectively connected to the vehicle frame 12. The right driver's cab 11 is installed on the right side of the upper part of the vehicle frame 12, and the right power room 15 is installed at the rear of the right driver's cab 11. The right engine 16 is housed in the room 15, the right side below the vehicle frame 12 is connected to the upper part of the right support 44, and the bottom of the right support 44 is connected to the rear crossbeam of the right snow shovel 45 through hinged joints. The upper part of the snow shovel 45 is connected to the lower bottom surface of the vehicle frame 12 through the...

Embodiment 12

[0046] Example 1.2 , track snow removal vehicle, same as embodiment 1.1, the difference is that: when no snow removal operation is carried out for a long time, the brush-throwing snow removal device is directly removed, and when the track snow removal vehicle is used as a rail car, the right side engine 16 is driven by the right side hydraulic power. The torque converter 41 and the right transmission shaft 42 drive the right bogie 43 to provide traction and travel power; the left engine 22 drives the left bogie 31 through the left hydraulic torque converter 33 and the left transmission shaft 32 to provide traction and travel at the same time power. Also can be that any set of two sets of power systems provides traction and walking power, and the other set does not use.

Embodiment 13

[0047] Example 1.3, The track snow removal vehicle, with embodiment 1.1, is different in that: transfer case 23, hydraulic pump 24, left side power room 25 and hydraulic oil tank 26 are installed in the inside of right side power room 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com