A structure and construction method of basement post-pouring belt

A post-cast belt and basement technology, which is applied in the field of construction and post-cast belt, can solve the problems of complex environment, thick bottom plate and dense steel bars of the post-cast belt, so as to simplify the construction process, reduce grout leakage and water seepage, and improve The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] The specific construction steps are as follows:

[0025] (1) Laying out on the underlayment:

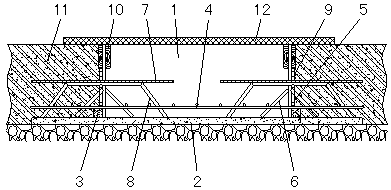

[0026] The cushion layer 2 at the post-pouring belt of the basement floor is a concrete cushion, and the width of the cushion layer 2 is 300mm wider than both sides of the post-casting belt 1. Before the reinforcement of the bottom plate 4 is tied, the position should be marked according to the design drawing, and the position line of the post-pouring tape should be popped up on the cushion layer or waterproof protection layer.

[0027] (2) Construction of mortar strips on both sides of the post-pouring belt:

[0028] The mortar strips 3 on both sides of the post-casting belt need to be constructed before the bottom plate reinforcement 4 is bound, and the size of the mortar strips is 40×40mm. Before the construction of the mortar strip, the position line of the mortar strip should be popped up on the cushion layer or the waterproof protection layer to ensure that the mortar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com