Single-layer latticed shell steel structure roof and installation method thereof

A single-layer reticulated shell and installation method technology, applied in the direction of roof, building components, building structure, etc., can solve the problems of weak structural rigidity, large structural span, large span, etc., to achieve fast and convenient construction, stable overall structure, guarantee The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

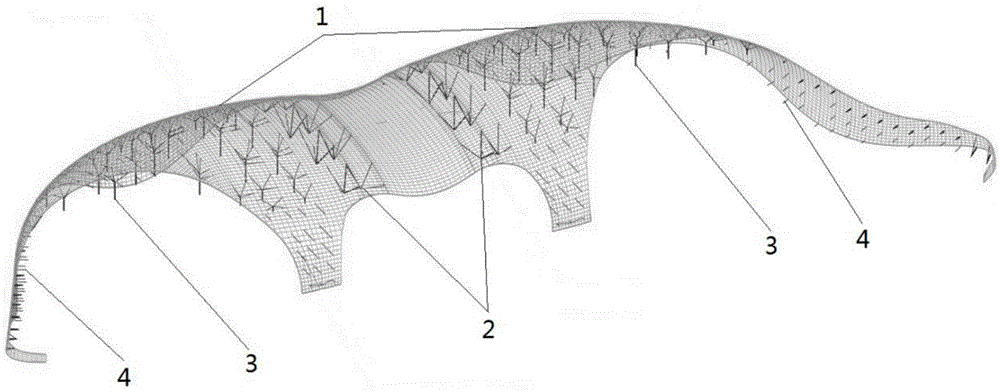

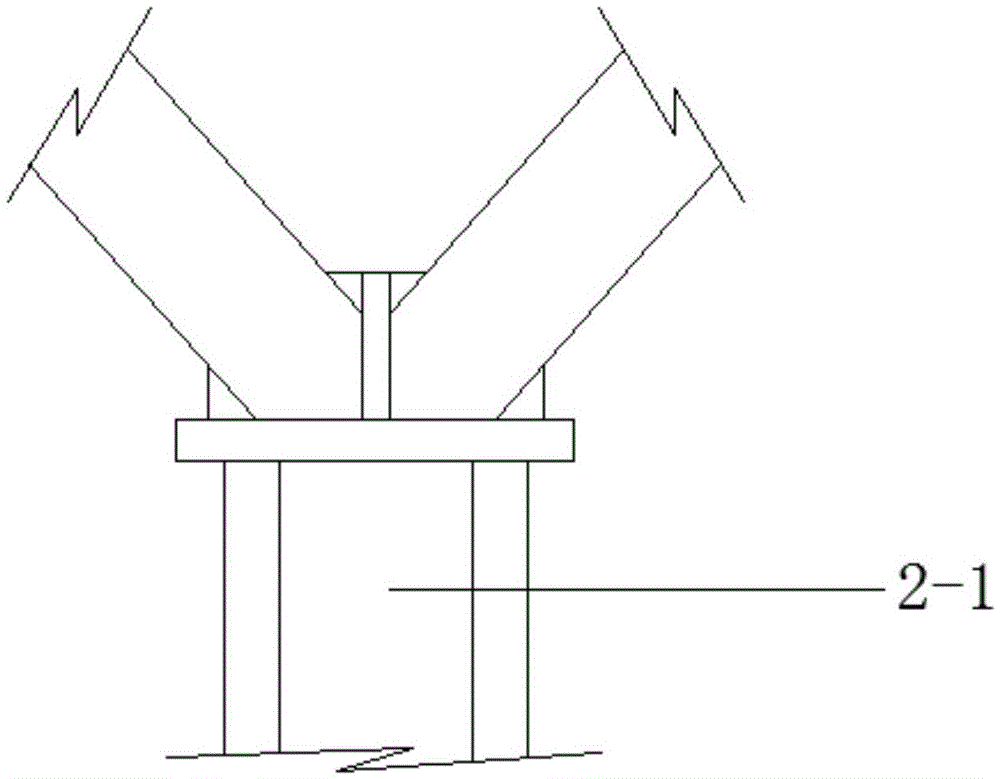

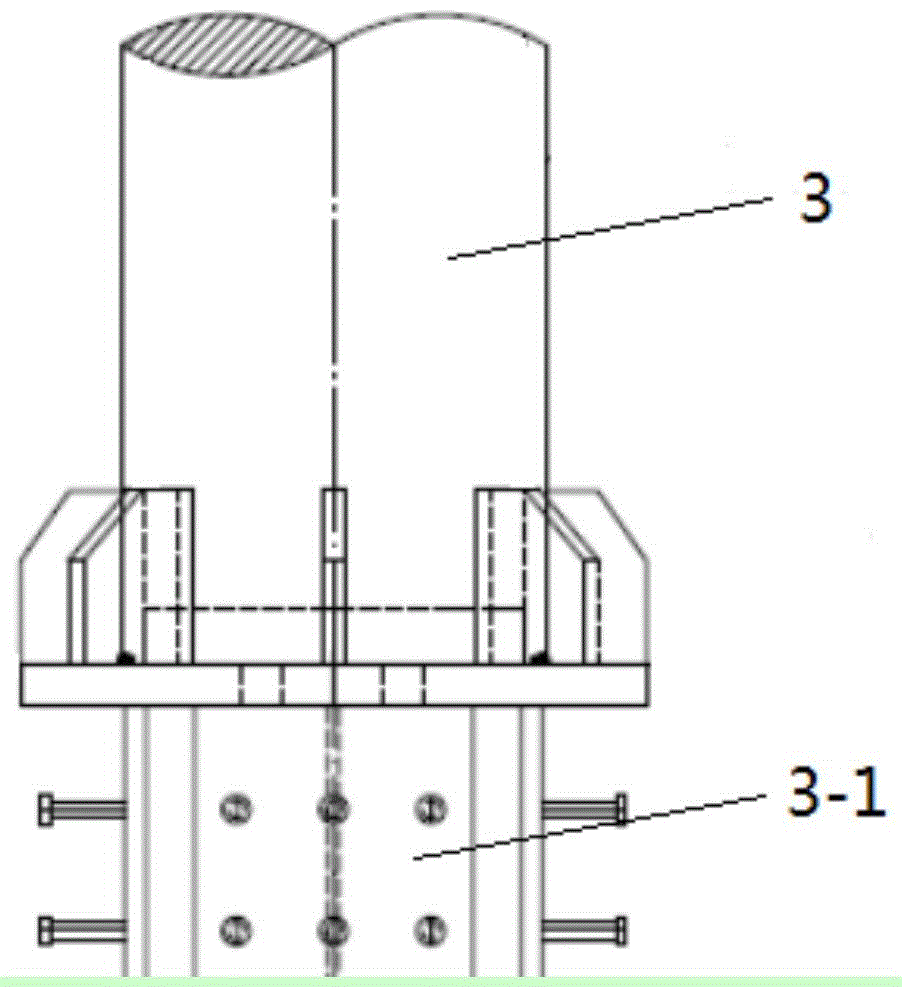

[0047] like figure 1A single-layer reticulated steel structure roof is shown, including roof grid 1, V-shaped support columns 2, tree-shaped support columns 3, and side elevation horizontal support bars 4; the roof grid 1 is composed of box-section steel rods The steel pipe joints are used to connect the rods; the V-shaped support column 2, the tree-shaped support column 3 and the horizontal support rod 4 of the side elevation are all the support structures of the roof grid 1, and are connected by hinged or rigid joints. connected with the surface mesh 1 in the same way; for example figure 2 The lower part of the shown V-shaped support column 2 is connected to the bottom structure through an I-shaped steel column 2-1, and each column is provided with 2 to 4 branches, and the branches are connected to the steel pipe nodes on the roof by rigid connection; image 3 , Figure 4 The lower part of the tree-shaped support column 3 shown is connected to the bottom structure through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com