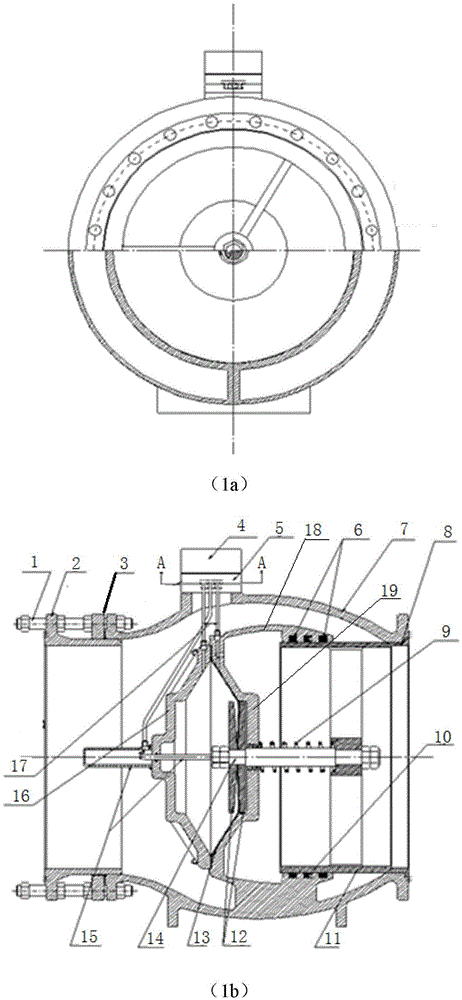

Built-in diaphragm type sleeve valve

A sleeve valve, diaphragm type technology, applied in valve details, safety valve, balance valve and other directions, can solve the problems of poor energy dissipation effect, poor anti-cavitation, poor anti-rubbish ability, etc., to achieve simple structure, sealing Good performance and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

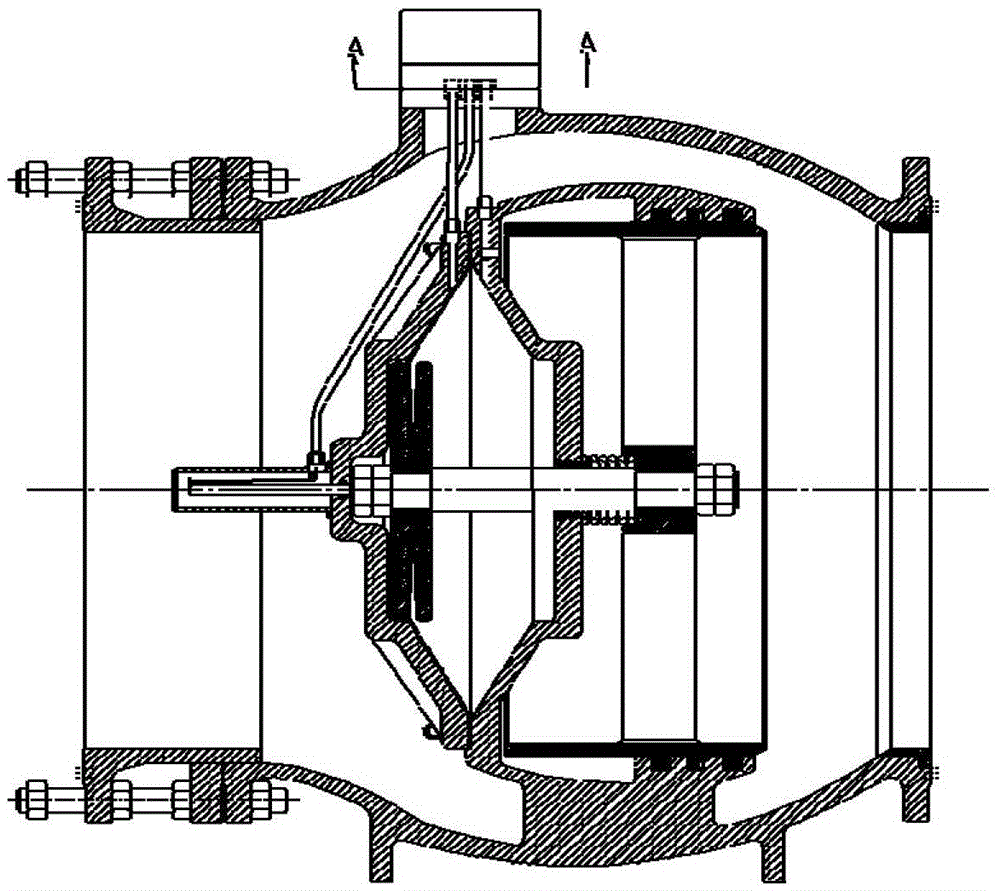

[0041] The present invention can work in pressure relief valve mode, such as Figure 4 As shown, the working principle of the pressure reducing valve is:

[0042] The principle is that the pressure signal collected by the pressure sensor behind the valve is transmitted to the remote central control PLC, and then the main valve is controlled by the PLC. Once the downstream flow increases and the pressure drops, the sensor immediately sends a signal to the PLC, and the PLC immediately instructs to open the solenoid valves B and D, the opening of the main valve increases, and the pressure immediately recovers to the design value, and the solenoid valves B and D are closed; When the flow rate decreases and the pressure rises, the PLC will command to open the solenoid valves A and C, the opening of the main valve will decrease, and the pressure will return to the set value, and the solenoid valves A and C will be closed.

Embodiment 2

[0044] The present invention can work in pressure relief valve mode, such as Figure 5 As shown, the working principle of the pressure relief valve is:

[0045] The principle is to collect the pressure signal by the pressure sensor in front of the valve and transmit it to the remote central control PLC, and then the PLC controls the main valve. Once the system pressure exceeds the set pressure, the sensor immediately sends a signal to the PLC, and the PLC immediately commands to open the solenoid valves B and D, close the solenoid valves A and C, and the main valve immediately opens to release pressure; otherwise, the system pressure is lower than the set value , then the PLC commands to close solenoid valves B and D, open solenoid valves A and C, and the main valve is closed.

Embodiment 3

[0047] The present invention can work in flow control valve mode, such as Figure 6 As shown, the working principle of the flow control valve is:

[0048]Once the remote central control PLC sets the standard given flow rate, the signal detected by the flowmeter is immediately fed back to the PLC. If the flow rate exceeds the set value, the PLC sends a signal command to open the solenoid valves A and C (the solenoid valves B and D are closed ), the pressure in the front chamber of the diaphragm drops, the main valve acts to close the valve, and the flow rate decreases to the set value; if the flow rate is lower than the set value, the flowmeter feeds back the signal to the PLC, and the central control sends an instruction to open the solenoid valve B, D (solenoid valves A and C are closed), the pressure in the back chamber of the diaphragm drops, the main valve opens, and the supplementary flow reaches a given value.

[0049] Figure 7 The piping diagram for the pneumatic con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com