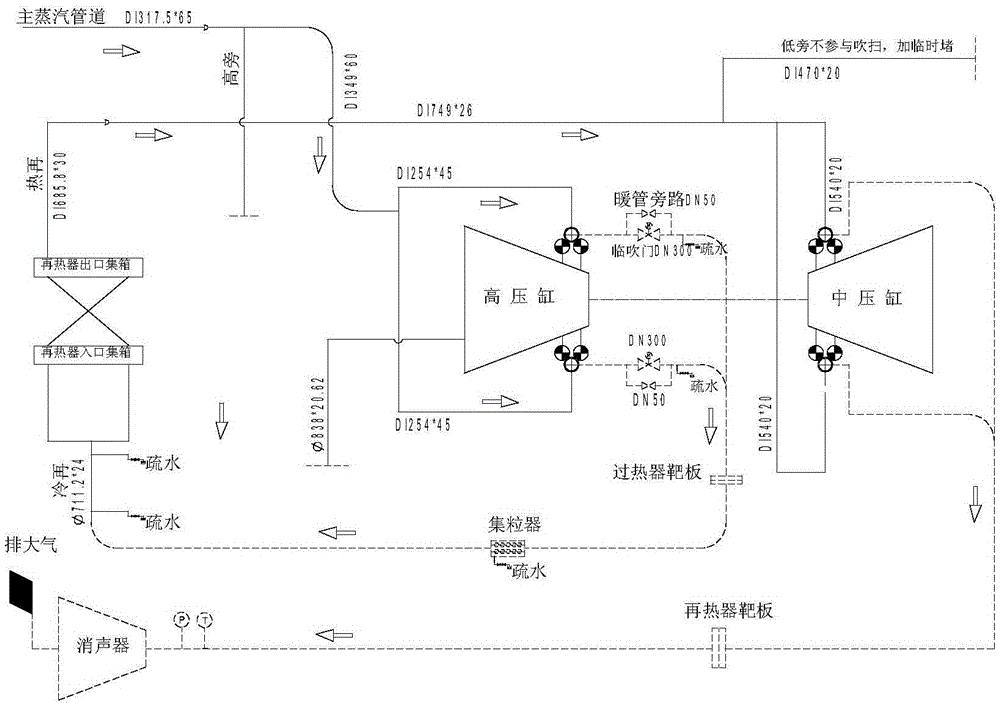

Steam extraction backheating and pressure stabilizing blowpipe system of generator set

A technology of generator set and pipe system, applied in the direction of water heater, fluid heater, heat exchanger, etc., which can solve the problems such as difficult to stabilize the blowpipe, no external heating steam source, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

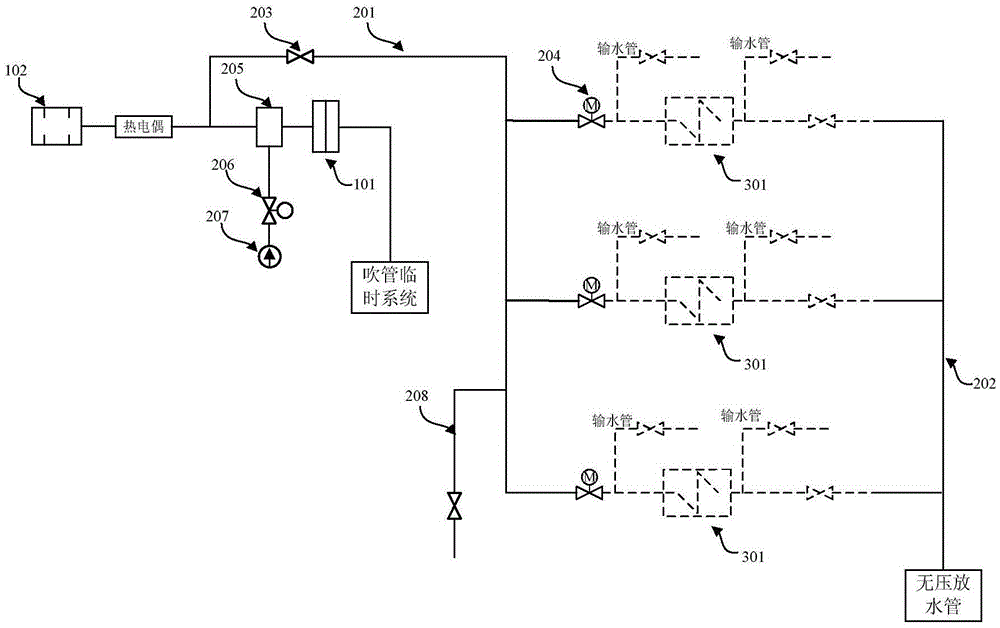

[0028] In order to make the technical features and effects of the present invention more obvious, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings. The present invention can also be described or implemented in other different specific examples. The equivalent transformations done within all belong to the protection category of the present invention.

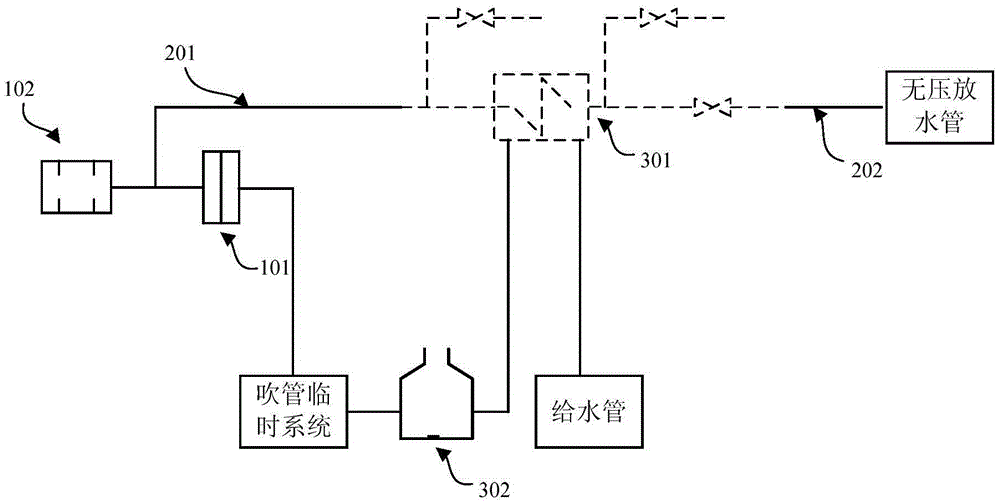

[0029] In one embodiment of the present invention, the blowpipe system for steam extraction, heat recovery and pressure stabilization of the generator set includes a temporary blowpipe system, which receives the steam generated by the boiler, and the blowpipe system also includes a temporary steam extraction system, such as figure 2 as shown, figure 2 It is a temporary system structure diagram of steam extraction in the steam extraction heat recovery and pressure stabilizing blowpipe system of a generator set according to an embodiment of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com