A method for real-time detection of heating of overhead line fittings joints

An overhead line, real-time detection technology, applied in the direction of measuring heat, thermometers and measuring devices using electrical/magnetic components directly sensitive to heat, etc. Achieve fast and accurate positioning and judgment, avoid manual line inspection work, and increase reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

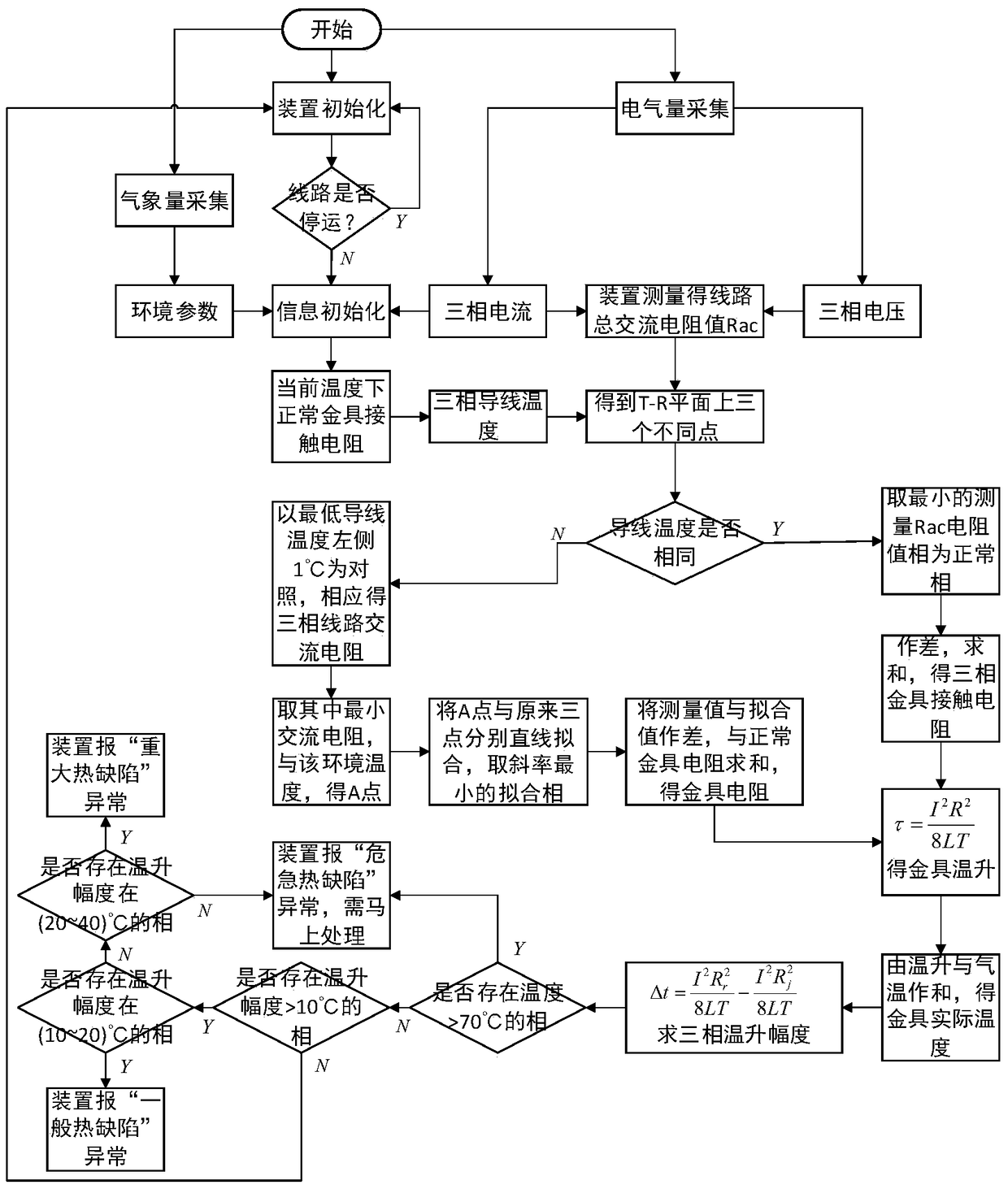

[0029] An embodiment 1 of the present invention is used for real-time detection of heating conditions of fittings joints of overhead lines. First of all, it is necessary to obtain the environmental meteorological parameters and the basic parameters of the line as the input of the calculation. Considering the need to ensure the consistency of environmental factors, this embodiment selects an operating line with 1 to 2 tension fittings within 1 km for implementation, and does not explicitly limit the scope of the operating voltage level. When the three-phase current is unbalanced, the zero-sequence current limit is generally set to 10% In (In is the rated current of the line).

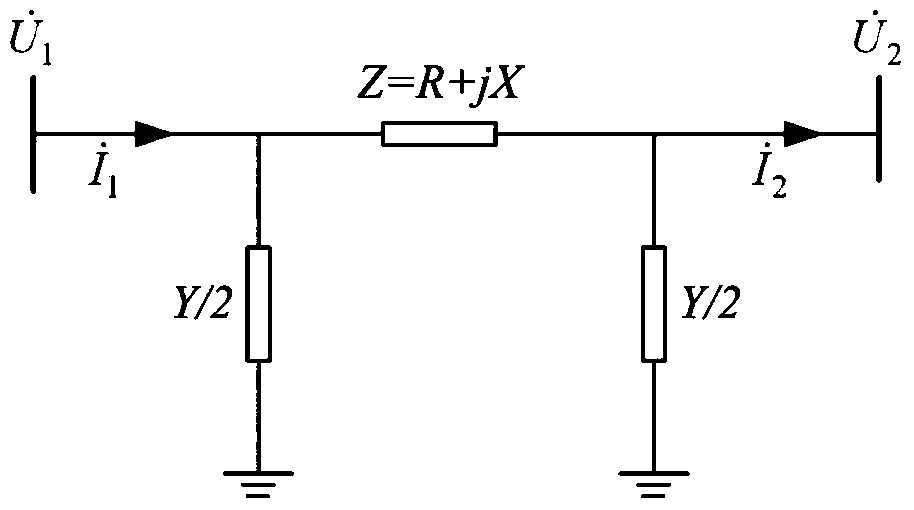

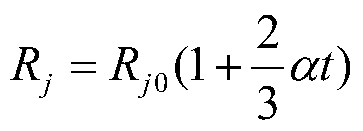

[0030] The calculation method of the wire temperature involves the determination of various environmental parameters, including the radiation heat dissipation coefficient, the heat absorption coefficient of the wire surface, the wind speed perpendicular to the wire, the sunlight intensity, and the ambien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com