Apparatus and method for measuring inclination and verticality of photoetching machine mask table

A technology of mask table and verticality, which is applied in the direction of measuring device, optical device, photolithographic exposure device, etc., which can solve the problems of shape fluctuation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

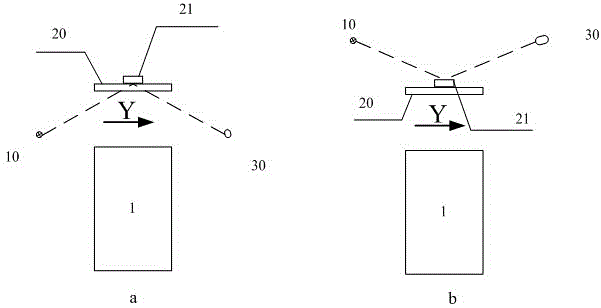

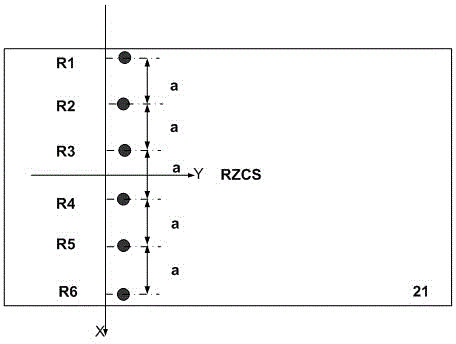

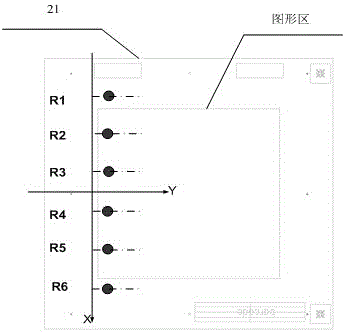

[0025] The invention provides a method for measuring the inclination and verticality of a mask table of a photolithography machine, which is applied in a scanning exposure system. The measuring device used in the method of the present invention includes a focusing and leveling system for measuring the shape of the mask table, such as figure 1 shown. Schematic diagram of possible photodetection structures for this system, which can also be implemented with grating structures, gas pressure, capacitive or mechanical means. The structure realizes the measurement of the height position change of the reticle during the horizontal movement of the mask table based on the principle of triangulation. These include light sources and photodetectors. The light source and photodetector are distributed on both sides of the objective lens. Such as figure...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap