A kind of composite soft magnetic material and preparation method thereof

A technology of composite soft magnetic and intermediate materials, applied in the direction of magnetic materials, inorganic material magnetic, magnetic objects, etc., can solve the problems of complex production process, achieve excellent magnetic permeability performance, simple insulation treatment, and material permeability. tuning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In the preparation method provided by the present invention, a rigid or elastic composite soft magnetic material is obtained by adjusting the type of the coating agent, and the elastic and flexible composite soft magnetic material can effectively prevent product breakage, thereby ensuring stable performance of the material.

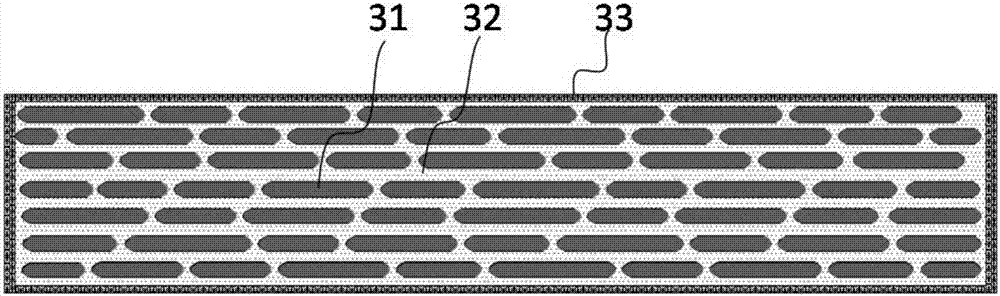

[0040] Preferably, the insulating coating, preforming steps and pressing steps in Preparation Method 1 are as follows: firstly, the polyimide coating agent is diluted in a certain proportion with N-methylpyrrolidone diluent, and then the diluted coating agent Mix with the scales to make a slurry, and then apply the slurry. During the coating process, the orientation of the scales can be controlled by applying a magnetic field, so that the scales are arranged in overlapping layers (that is, overlapping into a layered structure); The slurry after the cloth is dried to obtain a coated sheet. The temperature of the drying treatment is preferably 80-180 ...

Embodiment 1-12

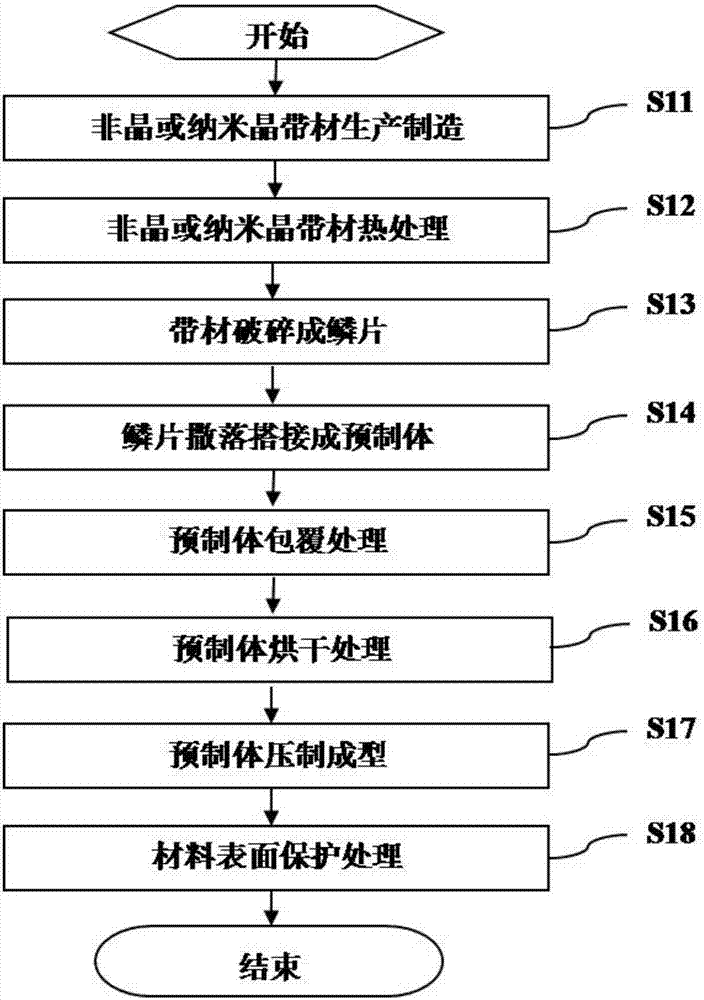

[0046] Examples 1-12 are composite soft magnetic materials prepared by the preparation method 2 of the present invention, and the specific process parameters of each example are shown in Table 1. The raw materials of embodiment 1-12 are amorphous or nanocrystalline strips, wherein the amorphous strips are made of Fe 78 Si 9 B 13 (at.%) Alloy formation, nanocrystalline ribbons are made of Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 The alloy (at.%) is formed, the thickness of the amorphous strip is 20 μm, and the width is 142 mm, and the thickness of the nanocrystalline strip is 18 μm, and the width is 60 mm. The specific preparation steps of the composite soft magnetic material are as follows:

[0047] (1) Carry out one-step heat treatment to amorphous or nanocrystalline ribbon, wherein, the heat treatment temperature of amorphous ribbon is respectively 380 ℃, 400 ℃ and 420 ℃, and the heat treatment time is 90 minutes; The heat treatment temperature of nanocrystalline ribbon is 510°...

Embodiment 13-22

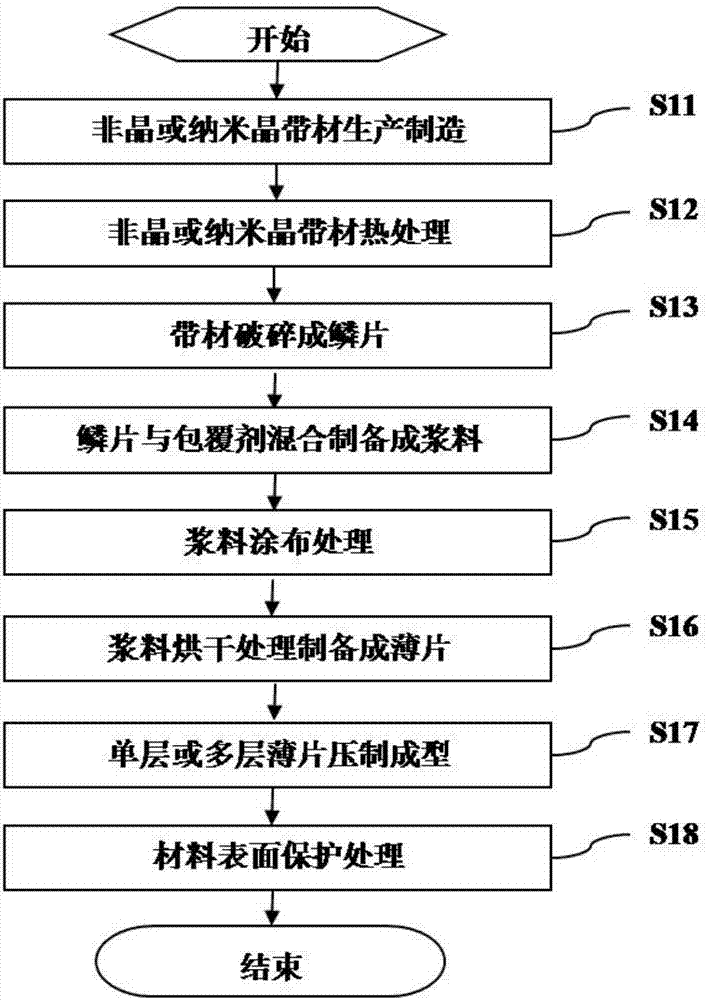

[0059] Examples 13-22 are for preparing composite soft magnetic materials by the preparation method 1 of the present invention, and the specific process parameters of each example are shown in Table 4. The raw materials of embodiment 13-22 are all amorphous or nanocrystalline strips, wherein the amorphous strips are made of Fe 78 Si 9 B 13 (at.%) Alloy formation, nanocrystalline ribbons are made of Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 The alloy (at.%) is formed, the thickness of the amorphous strip is 20 μm, and the width is 142 mm, and the thickness of the nanocrystalline strip is 18 μm, and the width is 60 mm. The specific preparation steps of the composite soft magnetic material are as follows:

[0060] (1) Carry out one-step heat treatment to the amorphous or nanocrystalline strips, wherein the heat treatment temperatures of the amorphous strips are 380°C, 400°C and 420°C respectively, and the heat treatment time is 90 minutes; the heat treatment temperatures of the nanocr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com