Mucky clay similar material used for simulating deep foundation pit construction mechanism and preparation method of similar material

A similar material and silt technology, which is applied in the field of silt clay similar materials used to simulate the construction mechanism of deep foundation pits and its preparation, can solve the problems of instability and damage, strong structure, endangering people's life and property safety, etc. Improves cohesion, improves permeability and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The concrete steps of described similar material preparation are as follows:

[0039] (1) Select Yellow River sand and soft clay without obvious impurities;

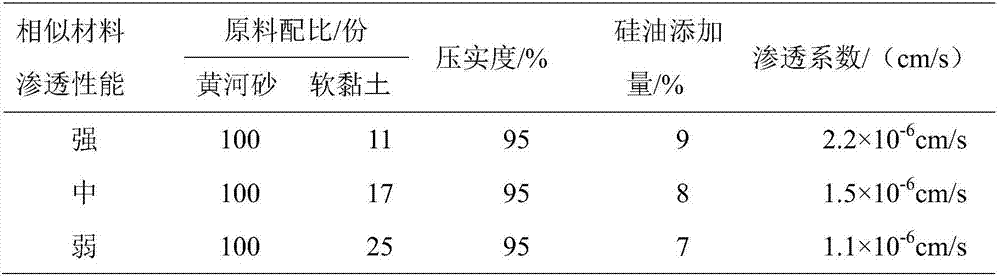

[0040] (2) Determine the permeability of similar materials required by the model test, and configure different proportions for comparative experiments;

[0041] (3) proportioning by weight: 100 parts of Yellow River sand and 11 parts of soft clay;

[0042] (4) Feeding and stirring, so that the materials are mixed evenly;

[0043] (5) Add silicone oil to the uniformly stirred material, the quality of silicone oil is 9% of the sum of the Yellow River sand and soft clay quality;

[0044] (6) Control the degree of compaction according to the needs of the experiment to make the model test material compacted and shaped. Under the condition of 95% degree of compaction, the water content is 68.7%, the void ratio is 1.924, and the permeability coefficient is 3.2×10 -6 cm / s, shear strength 0.52kPa, compression model 0.63...

Embodiment 2

[0046] The concrete steps of described similar material preparation are as follows:

[0047] (1) Select Yellow River sand and soft clay without obvious impurities;

[0048] (2) Determine the permeability of similar materials required by the model test, and configure different proportions for comparative experiments;

[0049] (3) Proportioning 100 parts of Yellow River sand and 17 parts of soft clay by weight;

[0050] (4) Feeding and stirring, so that the materials are mixed evenly;

[0051] (5) Add silicone oil to the uniformly stirred material, and the quality is 8% of the sum of the Yellow River sand and soft clay quality;

[0052] (6) Control the degree of compaction according to the needs of the experiment to make the model test material compacted and formed. In the case of 95% degree of compaction, the water content is 62.5%, the void ratio is 1.638, and the permeability coefficient is 2.6×10 -6 cm / s, shear strength 0.84kPa, compression model 0.92MPa.

Embodiment 3

[0054] The concrete steps of described similar material preparation are as follows:

[0055] (1) Select Yellow River sand and soft clay without obvious impurities;

[0056] (2) Determine the permeability of similar materials required by the model test, and configure different proportions for comparative experiments;

[0057] (3) Proportioning 100 parts of Yellow River sand and 25 parts of soft clay by weight;

[0058] (4) Feeding and stirring, so that the materials are mixed evenly;

[0059] (5) Add silicone oil to the uniformly stirred material, and the quality is 7% of the sum of the Yellow River sand and soft clay quality;

[0060] (6) Control the degree of compaction according to the needs of the experiment to make the model test material compacted and formed. Under the condition of 95% degree of compaction, the water content is 58.6%, the void ratio is 1.486, and the permeability coefficient is 1.8×10 -6 cm / s, shear strength 1.12kPa, compression model 1.47MPa. .

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com