Regenerators for external combustion heat engines

A heat engine and regenerator technology, applied in the direction of hot gas variable displacement engine devices, engine components, regenerative heat exchangers, etc., can solve the influence of heat engine thermal efficiency, reduce thermodynamic efficiency and mechanical efficiency, and produce eddy currents in working fluid And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

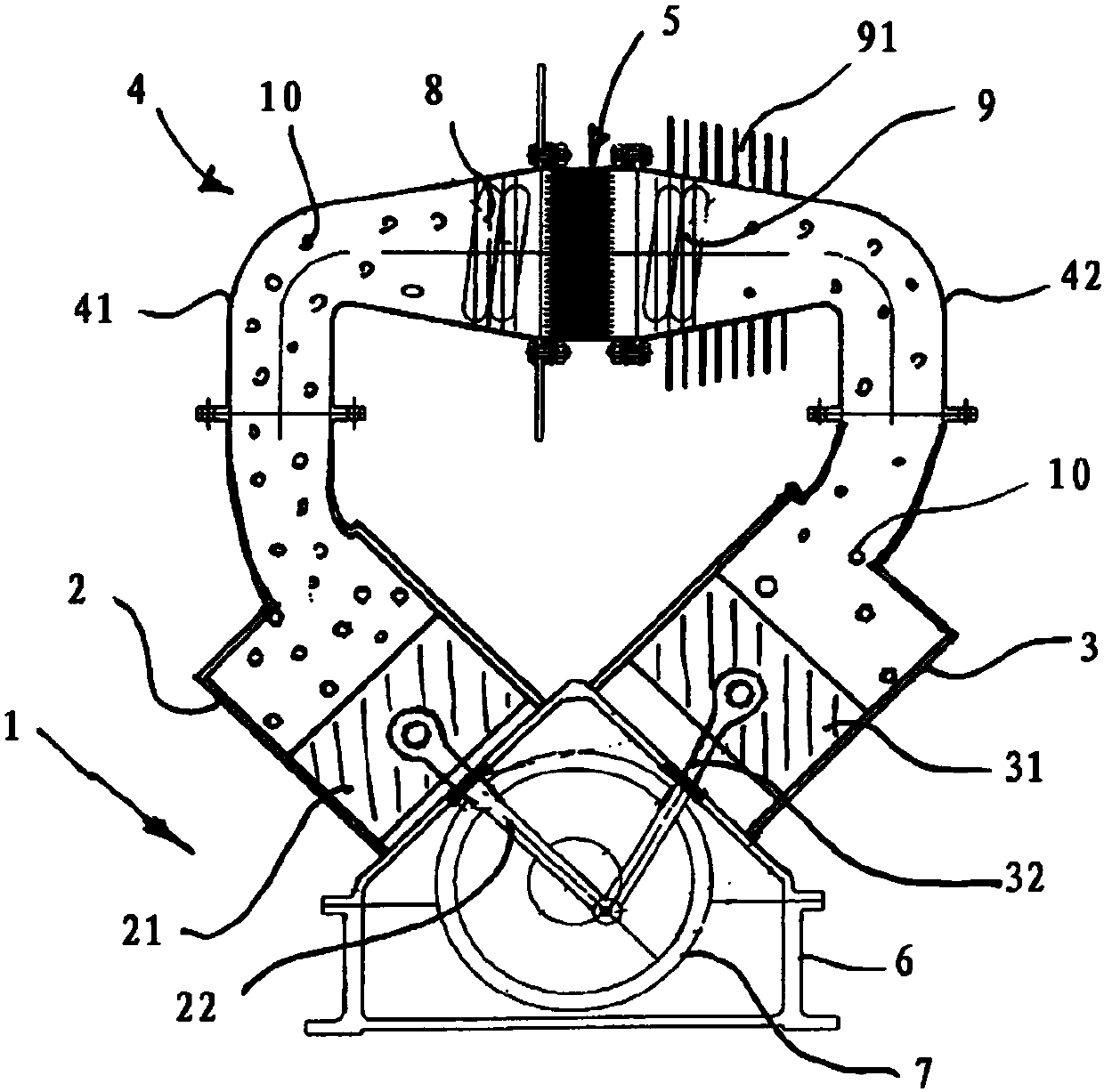

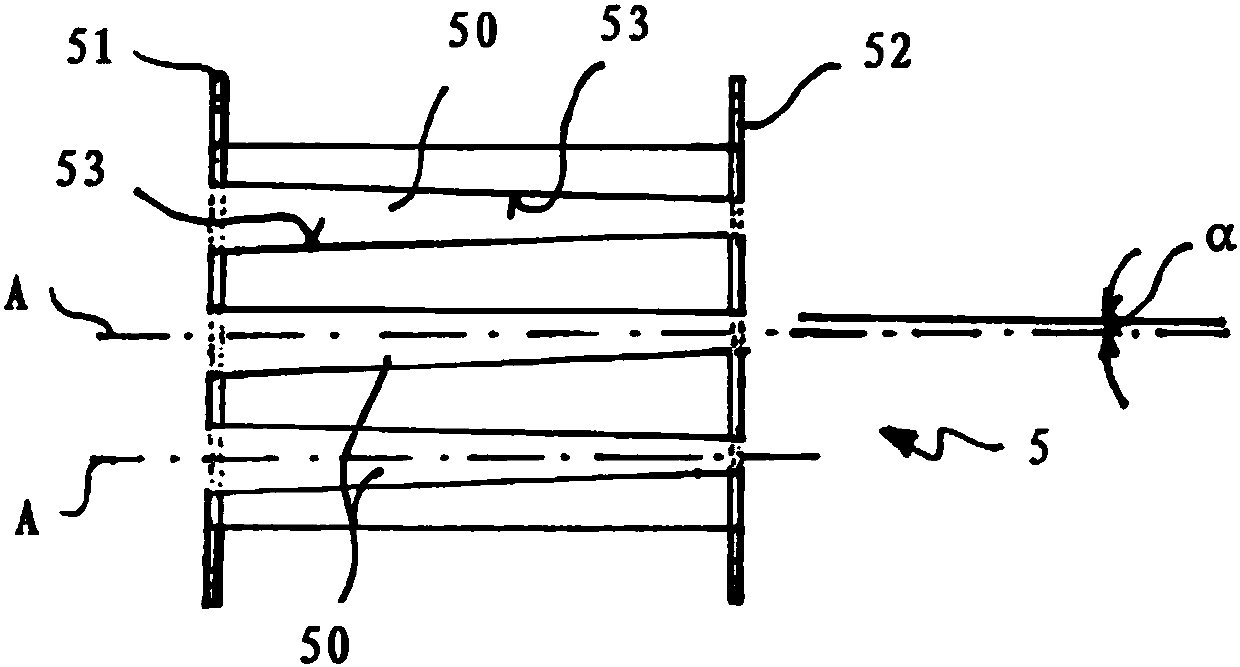

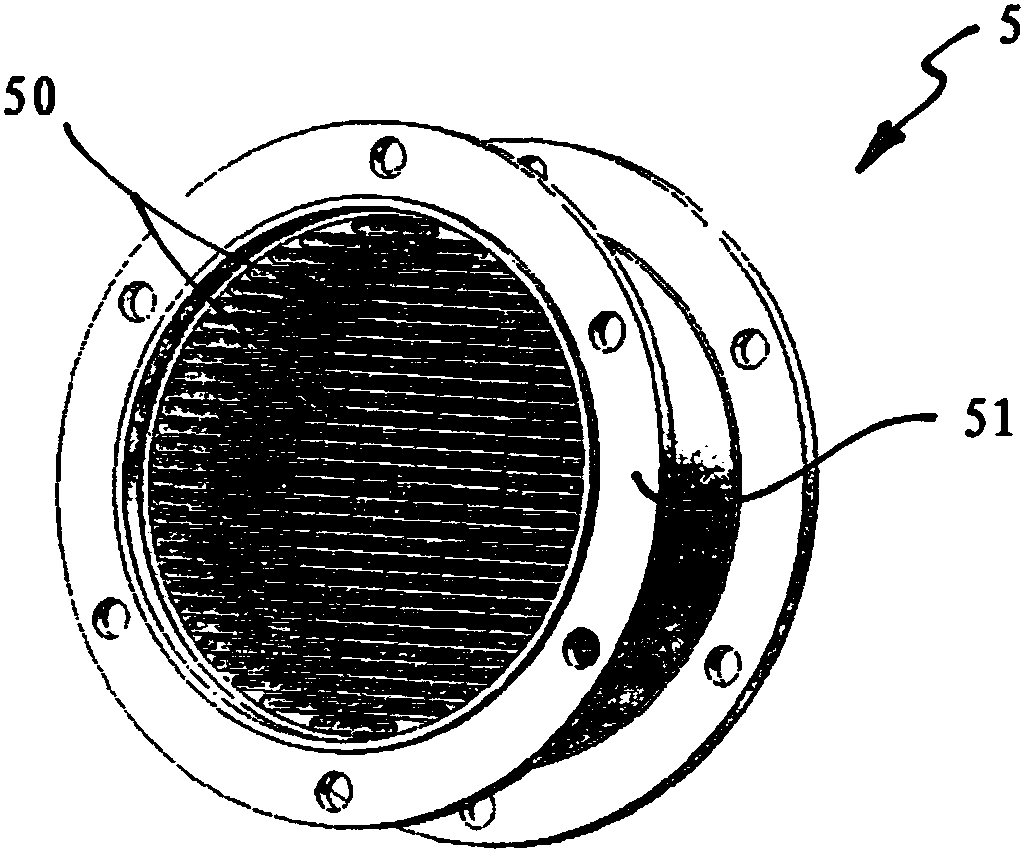

[0027] figure 1Schematically shows a sectional view of an alpha-type Stirling engine. The Stirling engine is a well known classic external combustion heat engine and is distinguished from other known types of external combustion heat engines by the inclusion of a regenerator. The Stirling engine is generally indicated by the number 1. A Stirling engine 1 of alpha-type configuration comprises a first cylinder 2 and a second cylinder 3 , wherein the respective pistons 21 , 31 of the first cylinder 2 and the second cylinder 3 move up and down periodically. The two cylinders 2 , 3 are connected via a conduit 4 for working fluid 10 comprising a first branch pipe 41 and a second branch pipe 42 . The cylinders 2, 3 and the pipe 4 form a closed system in which a working fluid 10, generally in gaseous form, is periodically conveyed from the first cylinder 2 to the second cylinder 3 and from the second cylinder 3 is sent back to the first cylinder 2. The working fluid 10 may be, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com