Puncturing system with automatic gap adjusting function

A technology of automatic adjustment and control system, applied in the direction of sewing tools and other directions, can solve the problems of limited accuracy, no automatic distance adjustment, positioning, and restriction of processing efficiency of personalized customized clothing processing industry, etc., to achieve high efficiency, The effect of high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

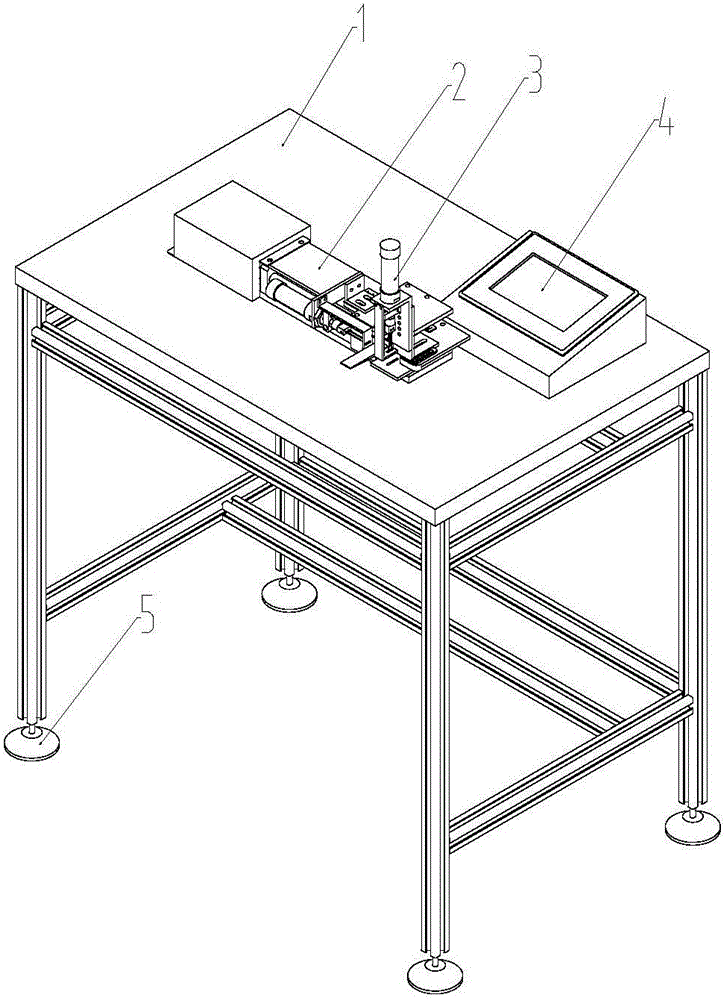

[0036] Such as figure 1 As shown, the automatic distance-adjusting piercing system includes an operating table 1 and a piercing system installed on the end surface of the operating table 1. The bottom of the legs of the operating table 1 is installed with feet 5 and fixed on the ground.

[0037] The piercing system includes a horizontal piercing system 2 , a vertical piercing system 3 and a positioning device 6 .

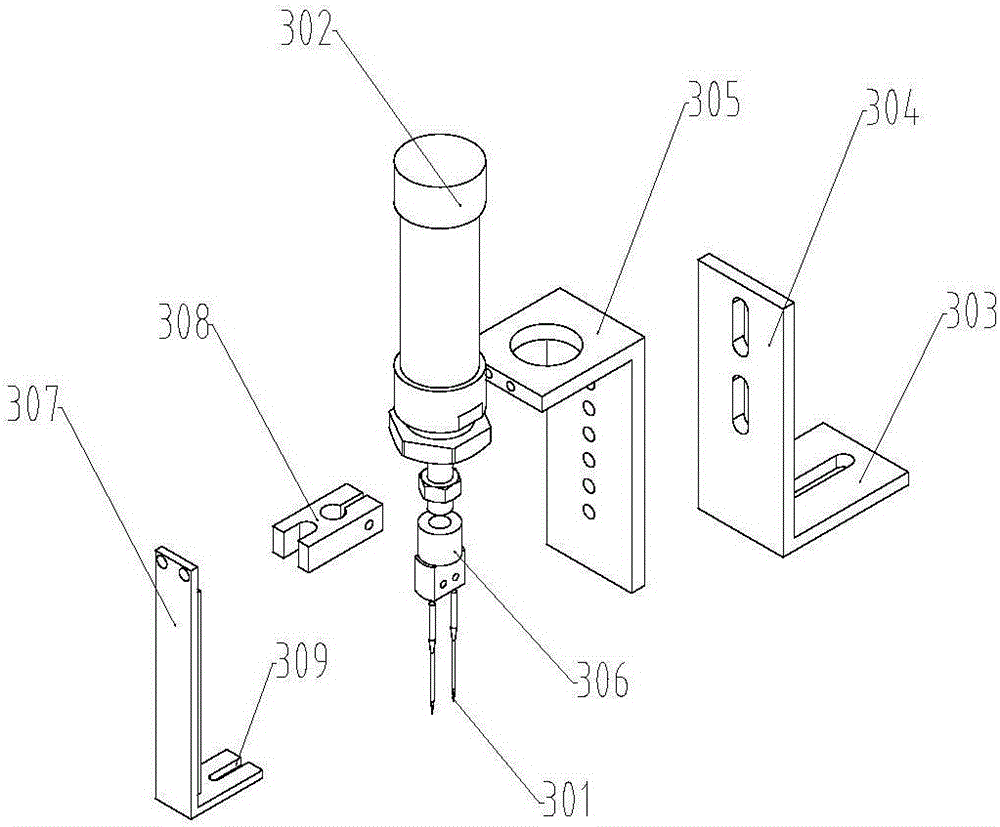

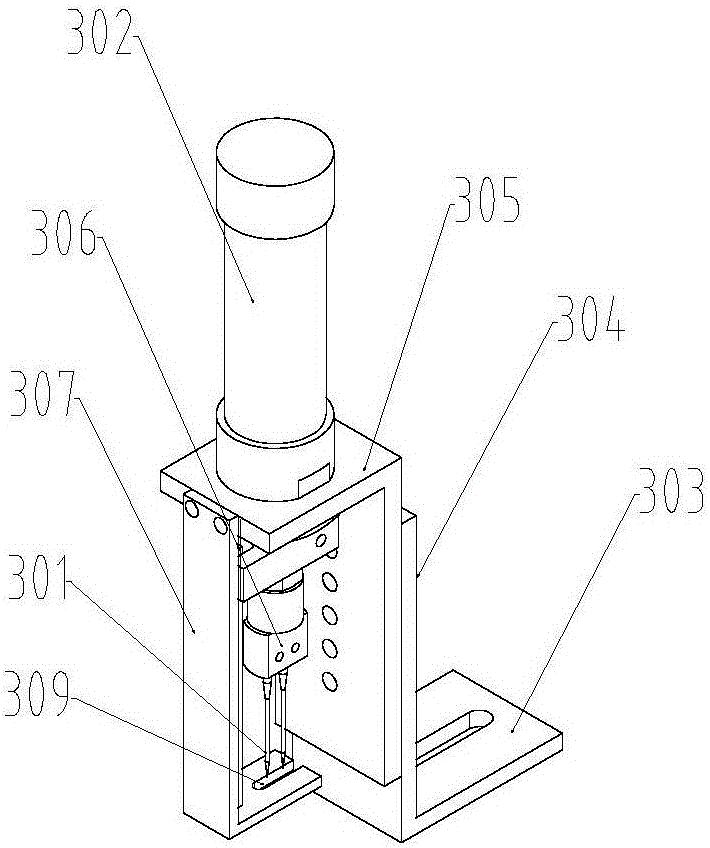

[0038] Such as figure 2 and image 3 As shown, the vertical piercing system 3 is fixedly installed on the end surface of the console 1 , and includes a vertical piercing needle 301 , a vertical cylinder 302 , a horizontal fixing base 303 and a vertical fixing seat 304 .

[0039] Wherein, the horizontal fixing base 303 and the vertical fixing base 304 can be a separate structure, or can be processed into an integrated structure. The horizontal fixing base 303 is used to install the entire vertical piercing system 3 on the operating platform 1 . The vertical fixi...

Embodiment 2

[0054] In order to simplify the design of the system structure, the structures of the vertical positioning guide device and the horizontal positioning guide device can also be omitted. The structure of this embodiment is as follows Figure 10 and Figure 11 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com