Wiping wet tissue for dairy cows and preparation method of wiping wet tissue

A technology for wet wipes and cows, which is applied in the field of cow wipes and its preparation, can solve the problems of large consumption of towels, increased workload, high labor intensity, etc., achieve good antibacterial and bactericidal effects, improve quality, and reduce labor The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

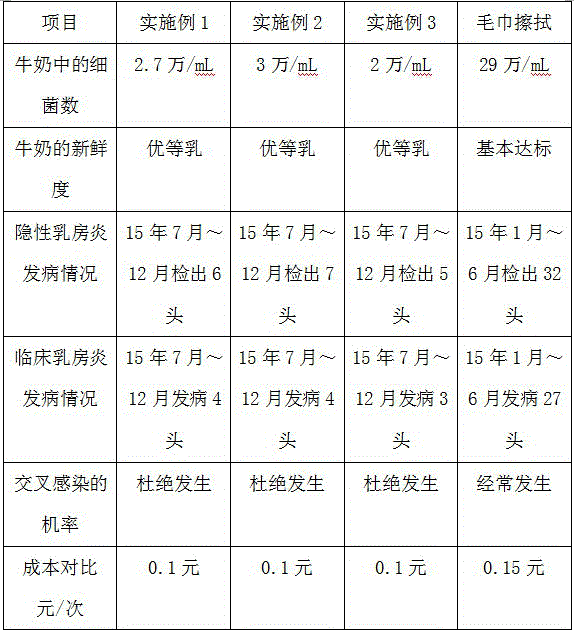

Embodiment 1

[0040] The dosing of the cow wiping wet wipes in this embodiment consists of the following components in parts by weight: 0.3 part of chlorhexidine glucose, 0.6 part of propylene glycol, 0.15 part of methyl benzoate, and 0.2 part of isopropyl p-hydroxybenzoate , 0.3 parts of ethylenediaminetetraacetic acid, 0.6 parts of dioctyl carbonate, 14.5 parts of edible alcohol, 0.15 parts of allantoin, 83.12 parts of deionized water and 0.08 parts of 2-bromo-2-nitro-1,3-propanediol.

Embodiment 2

[0042] The dosing of the cow wiping wet wipes in this embodiment consists of the following components in parts by weight: 0.1 part of chlorhexidine glucose, 0.4 part of propylene glycol, 0.05 part of methyl benzoate, and 0.1 part of isopropyl p-hydroxybenzoate , 0.2 parts of ethylenediaminetetraacetic acid, 0.4 parts of dioctyl carbonate, 15.5 parts of edible alcohol, 0.05 parts of allantoin, 83.16 parts of deionized water and 0.04 parts of 2-bromo-2-nitro-1,3-propanediol.

Embodiment 3

[0044] The dosing of the cow wiping wipes in this embodiment consists of the following components by weight: 0.2 part of chlorhexidine glucose, 0.5 part of propylene glycol, 0.1 part of methyl benzoate, and 0.15 part of isopropyl p-hydroxybenzoate , 0.25 parts of ethylenediaminetetraacetic acid, 0.5 parts of dioctyl carbonate, 15 parts of edible alcohol, 0.1 part of allantoin, 83.14 parts of deionized water and 0.06 parts of 2-bromo-2-nitro-1,3-propanediol.

[0045] Adopt the dosing of above-mentioned embodiment 1~3, the method for preparing dairy cow wiping wet tissue, this preparation method comprises the following steps:

[0046] (1) Weigh the above-mentioned methyl benzoate, isopropyl p-hydroxybenzoate, dioctyl carbonate and allantoin respectively, and weigh the methyl benzoate, isopropyl p-hydroxybenzoate, Add dioctyl carbonate and allantoin in sequence, then stir evenly, and finally raise the temperature to 85°C to obtain mixed solution A;

[0047] (2) Weigh the chlorhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com