Thermal treatment of hydrothermal precursors to obtain ws 2 /wo 3 hollow microsphere method

A hollow microsphere and precursor technology, which is applied in the fields of water pollutants, microsphere preparation, water/sewage treatment, etc., can solve the problems of danger in the sulfidation reduction process, influence on product quality, danger of high temperature sulfidation, etc., and achieve uniform size, The effect of eliminating influencing factors and having few influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

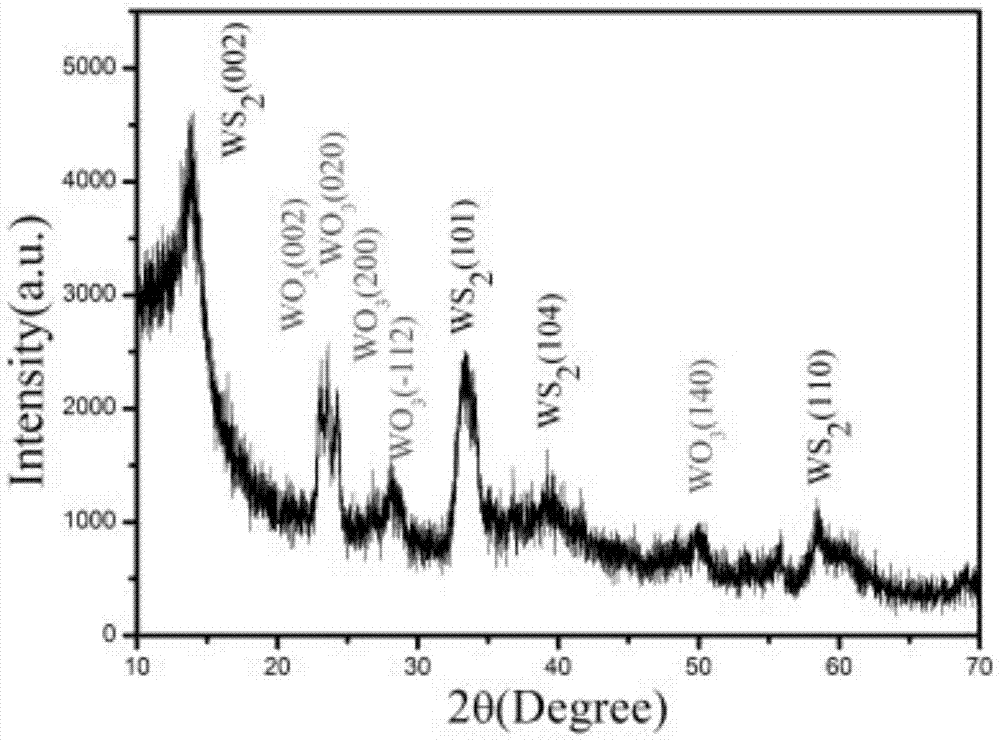

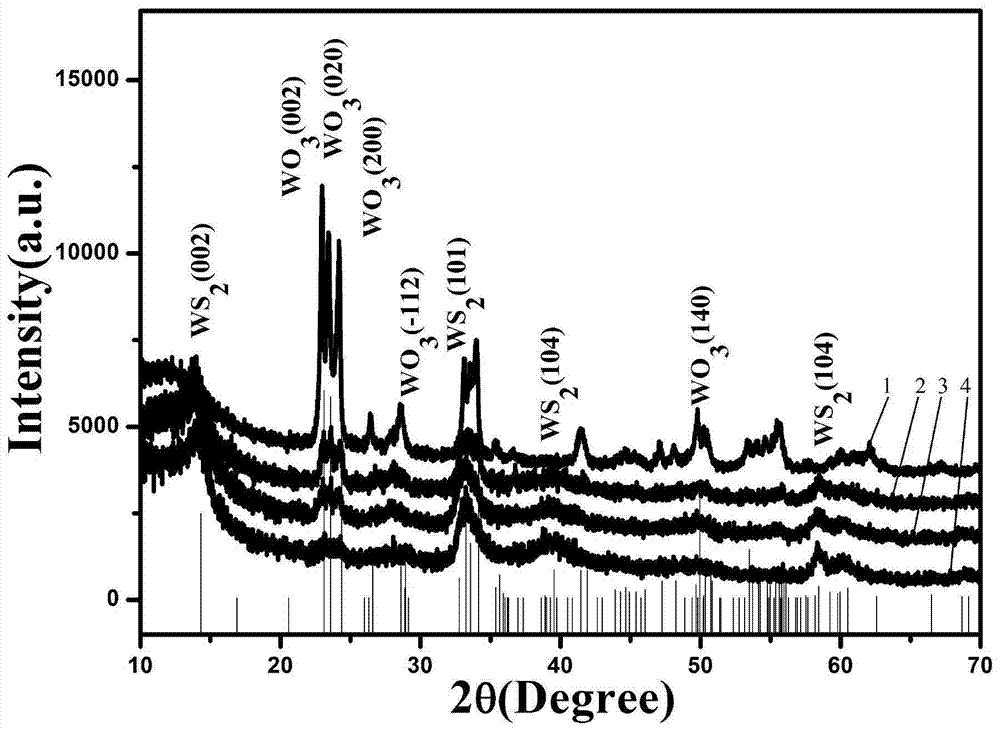

[0022] The first step is to prepare the reaction solution: Weigh 1.19055g of tungsten hexachloride and 1.125g of thioacetamide respectively with an electronic balance, add them to 80mL of deionized water, and stir magnetically for 30min, during which O 2 10min.

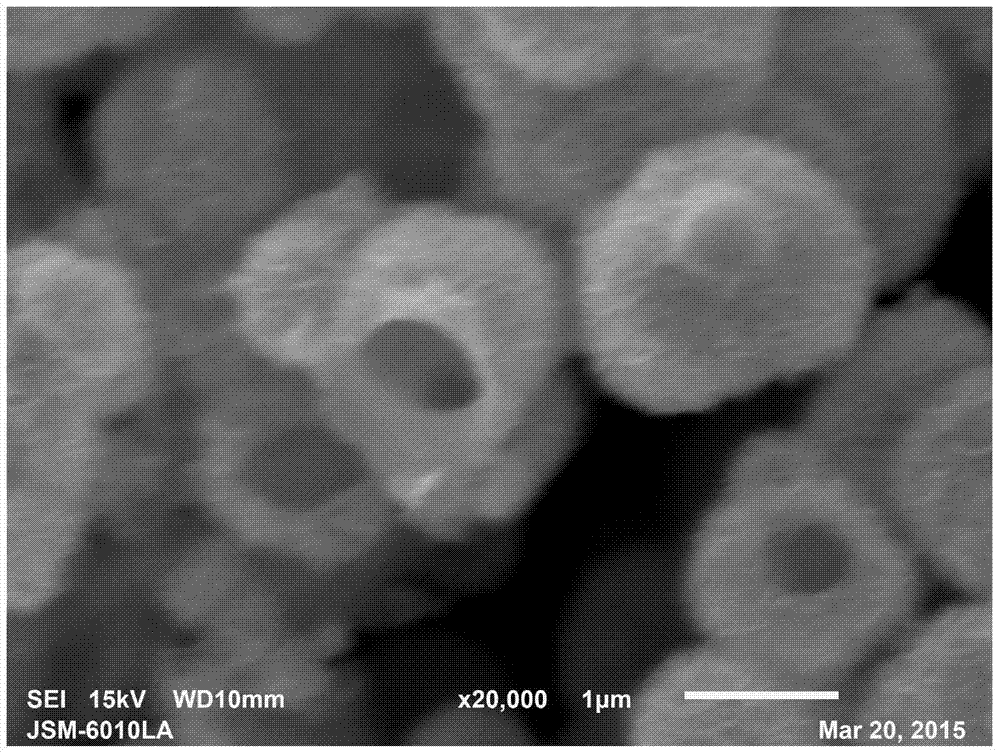

[0023] The second step, hydrothermal preparation of WS 2 / WO 3 Precursor: Add the reaction liquid into the inner tank of the reaction kettle in an amount of 2 / 3 of the volume of the inner tank of the reactor. In the high-pressure reactor, at 235°C, hydrothermally treat the reaction solution for 24 hours to obtain a hollow Microspherical WS 2 / WO 3 Precursor.

[0024] The third step, heat treatment of the WS 2 / WO 3 Precursor: at 500°C, in N 2 Heat treatment of the WS in a protective atmosphere 2 / WO 3 Precursor 1h, the product WS 2 / WO 3 hollow microspheres.

example 2

[0026] The first step is to prepare the reaction solution: Weigh 1.19055g of tungsten hexachloride and 1.125g of thioacetamide respectively with an electronic balance, add them to 80mL of deionized water, and stir magnetically for 25min, during which O 2 15min.

[0027] The second step, hydrothermal preparation of WS 2 / WO 3 Precursor: Add the reaction liquid into the inner tank of the reaction kettle in an amount of 2 / 3 of the volume of the inner tank of the reactor. In the high-pressure reactor, the reaction solution is hydrothermally treated for 30 hours at a temperature of 230°C to obtain a hollow Microspherical WS 2 / WO 3 Precursor.

[0028] The third step, heat treatment of the WS 2 / WO 3 Precursor: at 470°C, in N 2 Heat treatment of the WS in a protective atmosphere 2 / WO 3 Precursor 1.5h, get the product WS 2 / WO 3 hollow microspheres.

example 3

[0030] The first step is to prepare the reaction solution: Weigh 1.19055g of tungsten hexachloride and 1.125g of thioacetamide respectively with an electronic balance, add them to 80mL of deionized water, and stir magnetically for 35min, during which O 2 5min.

[0031] The second step, hydrothermal preparation of WS 2 / WO 3 Precursor: add the reaction solution into the inner tank of the reaction kettle, the addition amount is 2 / 3 of the volume of the inner tank of the reaction kettle, and in the high-pressure reactor, at 240 ° C, hydrothermally treat the reaction solution for 20 hours to obtain a hollow Microspherical WS 2 / WO 3 Precursor.

[0032] The third step, heat treatment of the WS 2 / WO 3 Precursor: at a temperature of 520°C, in N 2 Heat treatment of the WS in a protective atmosphere 2 / WO 3 Precursor 0.5h, the product WS 2 / WO 3 hollow microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com