Method for preparing efficient bactericide silver/graphite phase carbon nitride composite material

A technology of graphite phase carbon nitride and composite materials, applied in chemical instruments and methods, botanical equipment and methods, biocides, etc., can solve the problem that the bactericidal effect needs to be improved, and achieve the effect of strong bactericidal ability and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

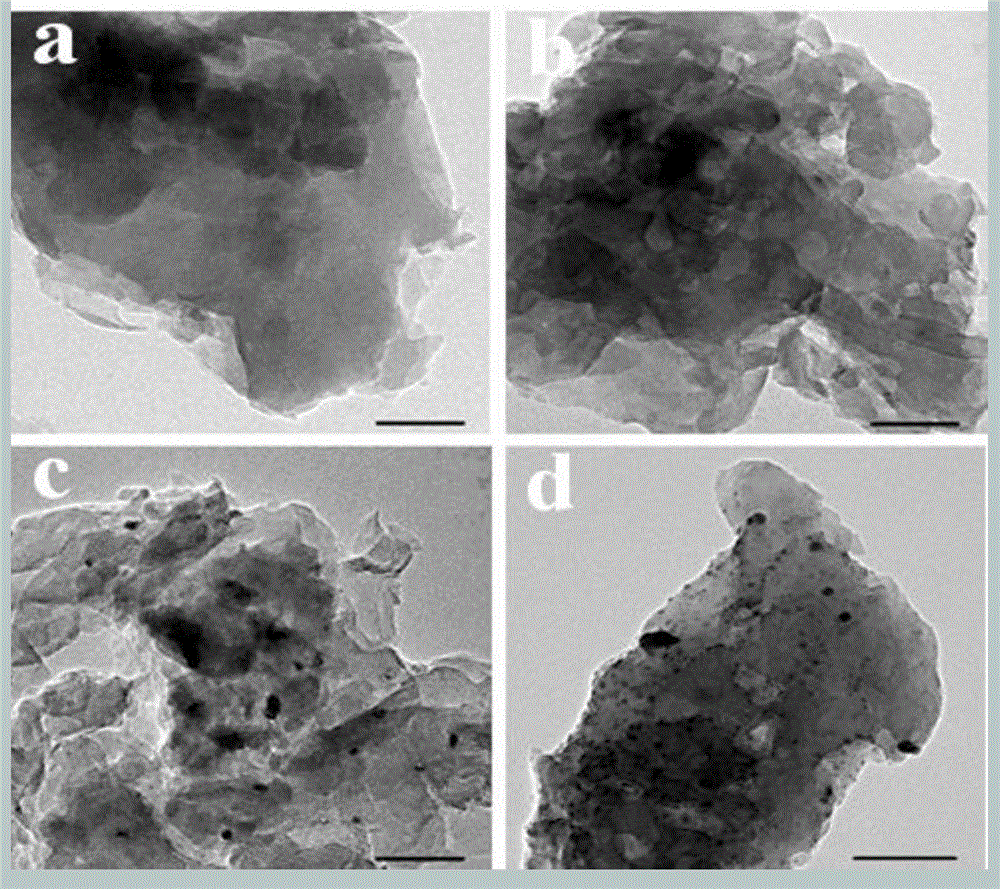

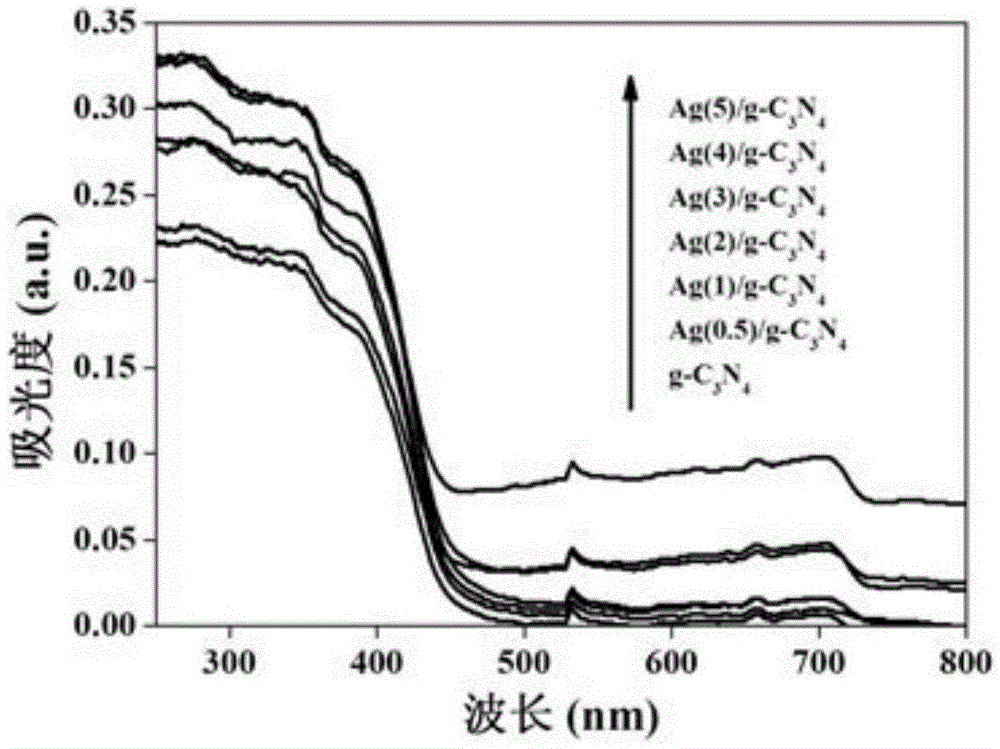

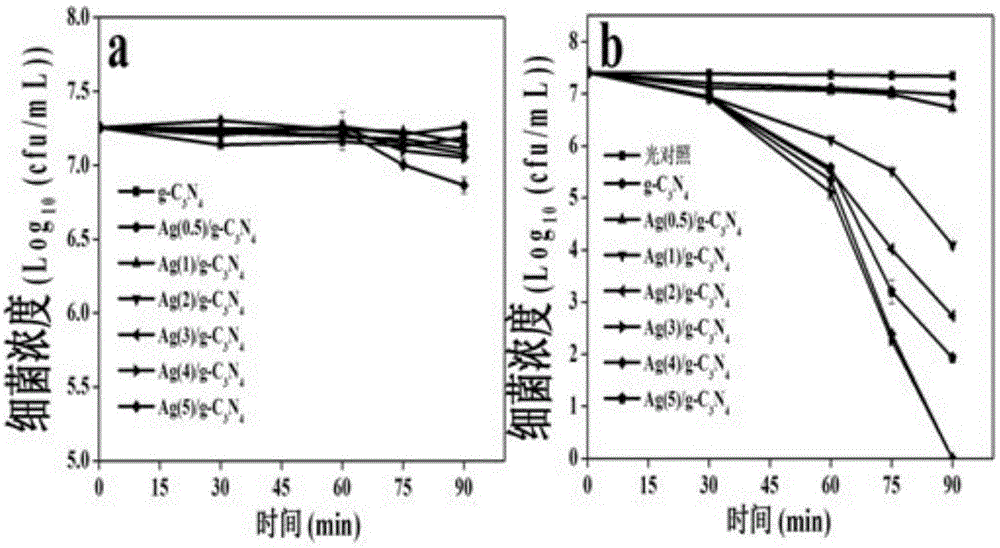

Image

Examples

Embodiment

[0024] A preparation method of high-efficiency bactericide silver / graphite phase carbon nitride composite material, the steps are as follows:

[0025] (1) Graphite phase carbon nitride (g-C 3 N 4 ) preparation

[0026] 1) Transfer melamine into a crucible with a lid, raise the temperature to 550°C at a heating rate of 2.3°C / min, and keep it for 4h. After cooling to room temperature, grind the obtained yellow powder in an agate mortar, and the obtained product is poly layer g-c 3 N 4 ;

[0027] 2) The above 1.5g multi-layer g-C 3 N 4 Add 450 mL of ethanol aqueous solution to obtain a mixed solution. The volume ratio of absolute ethanol and deionized water in the ethanol aqueous solution is 3:1. The above mixed solution is ultrasonicated for 10 h, and then the obtained yellow suspension is centrifuged at 3000 r / min for 10 min to remove untreated stripped g-C 3 N 4Granules, and then centrifuge the obtained milky white suspension at 10000r / min for 5min, and dry the obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com