Intelligent general-purpose automatic stamping detection device for Lamp LEDs

A detection device and automatic detection technology, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as automatic stamping, scratches on the surface of the pipe body, hidden safety hazards, etc., to shorten the production cycle and reduce production costs. Cost, the effect of enhancing the image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

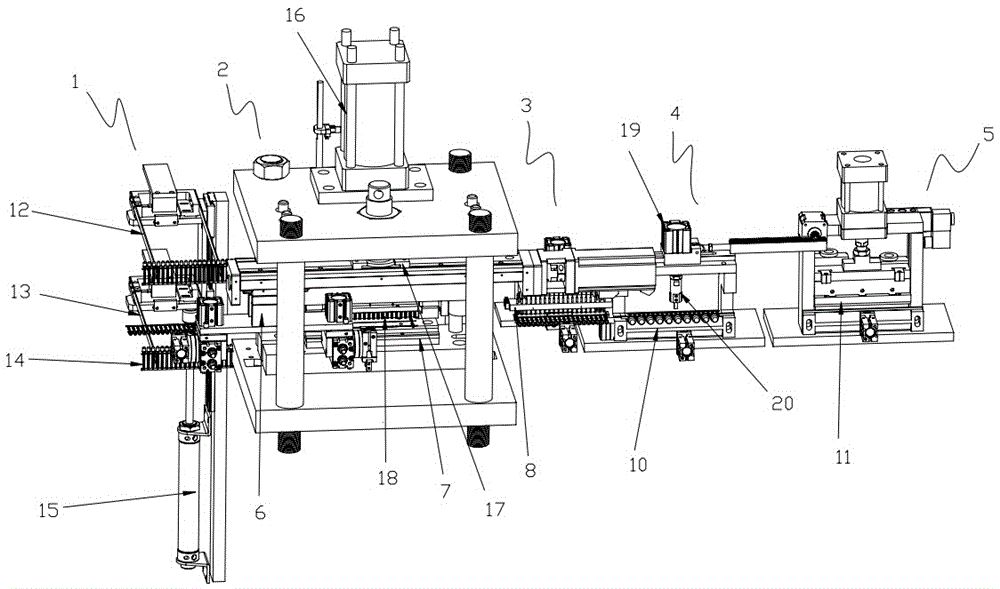

[0030] A kind of LampLED intelligent universal automatic punch detection device described in Embodiment 1, such as figure 1 As shown, it includes a movable intelligent manipulator system, a multi-layer rack feeding system 1, a synchronous double automatic stamping system 2, an automatic detection system 3, an automatic removal of defective products system 4 and an automatic cutting and packaging system 5.

[0031] The mobile intelligent manipulator system includes the intelligent manipulator that can move and place the in-line LED array, the power device and the signal sensor controller that control the action of the intelligent manipulator.

[0032] Multi-layer rack feeding system, including the rack that can be hung with 14 in-line LED rows, the photoelectric sensor that senses whether the in-line LED row is hung on the material rack, and the push rod that pushes the in-line LED row into the working position 1. Position the in-line LED row and place it on the automatic grabb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com