Material taking and releasing manipulator

A technology for manipulators and pick-and-place materials, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of uncertain personal safety of workers, impact on product quality, inaccurate positioning, etc., and achieve compact structure, low manufacturing cost, and translational movement fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

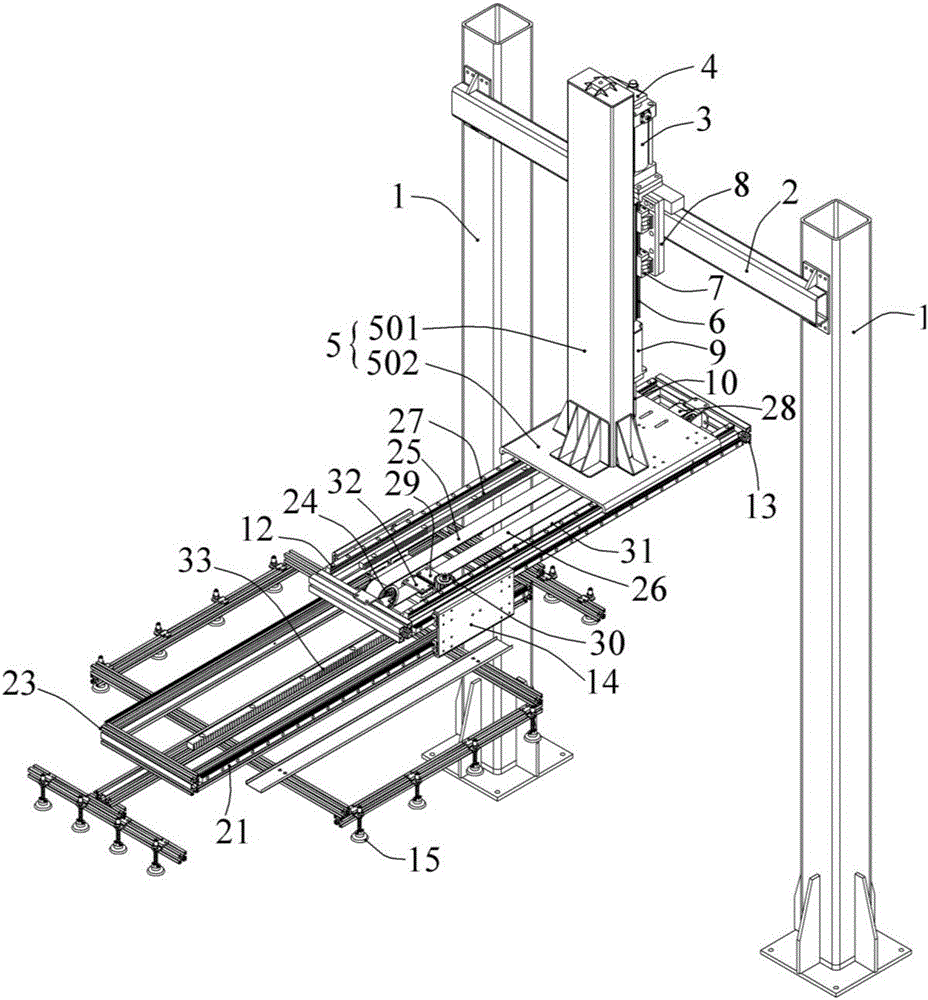

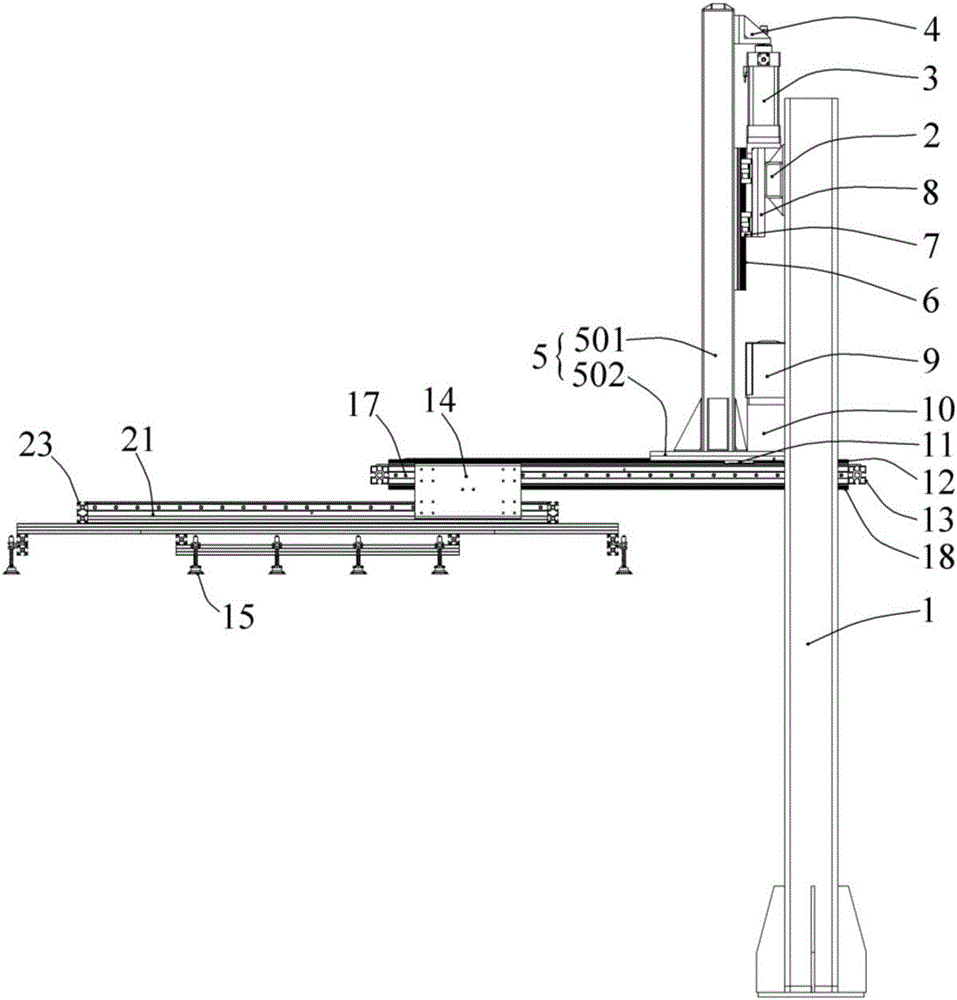

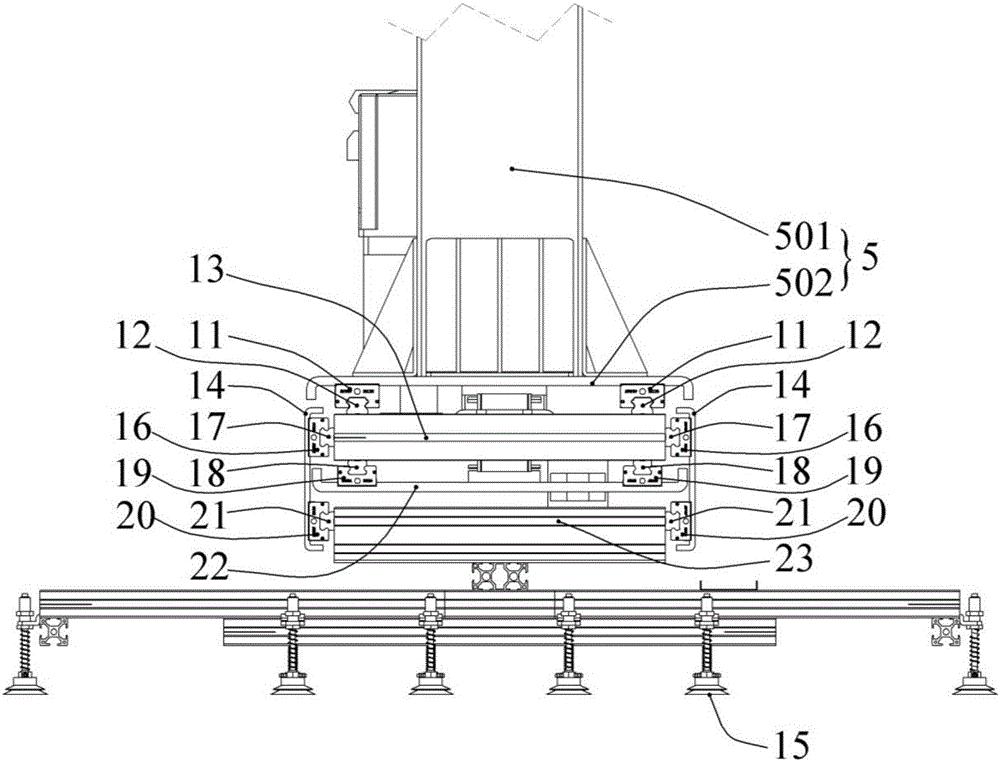

[0024] like Figure 1 to Figure 4 As shown, the pick-and-place manipulator of the present invention is composed of a frame assembly, a vertical movement assembly, a horizontal movement assembly and a suction cup assembly capable of picking up and putting down materials.

[0025] The frame assembly is composed of two support columns 1 and a crossbeam 2 connected between the two support columns 1, and the two support columns 1 can be fixed on the site where the pick-and-place manipulator is placed. The above-mentioned vertical motion assembly is provided with a cylinder 3, a connecting seat 4, a L-like bracket 5 and a first linear sliding pair, wherein the L-like bracket 5 is composed of a vertical rod part 501 and a horizontal plate connected to the lower end surface of the vertical rod part 501 502; the cylinder 3 is fixed on the beam 2, and the piston rod of the cylinder 3 is set upwards, and the upper end of the vertical rod part 501 is fixedly connected with the piston rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com