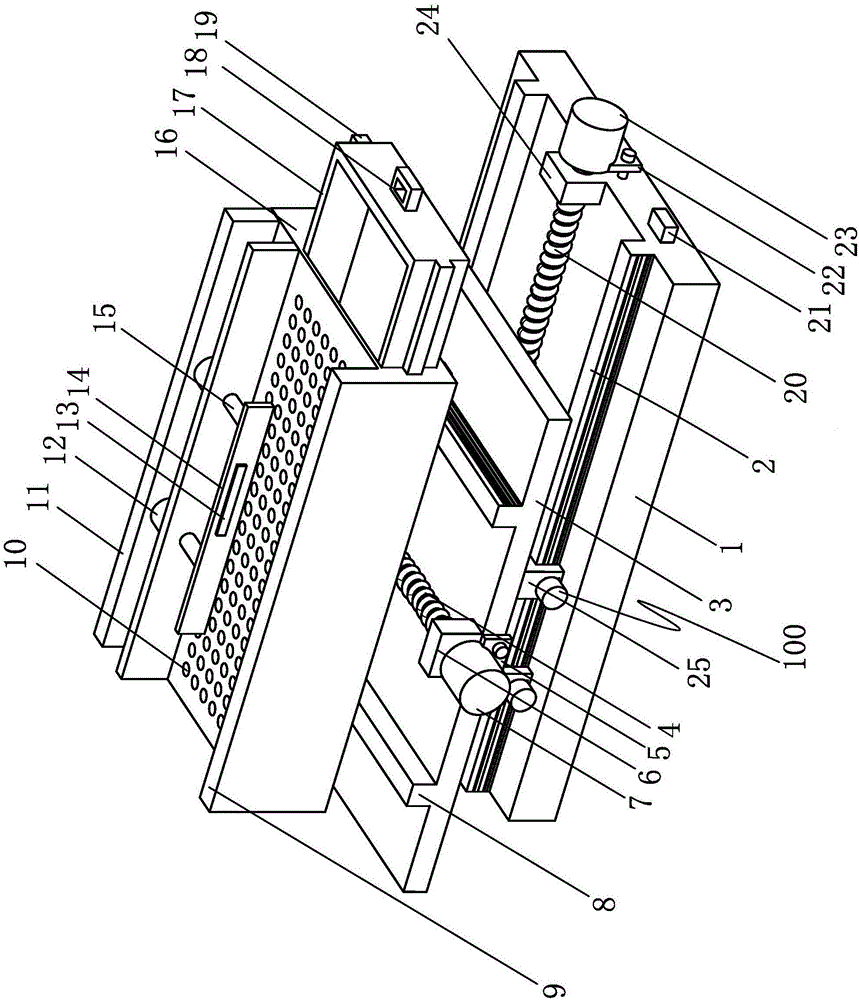

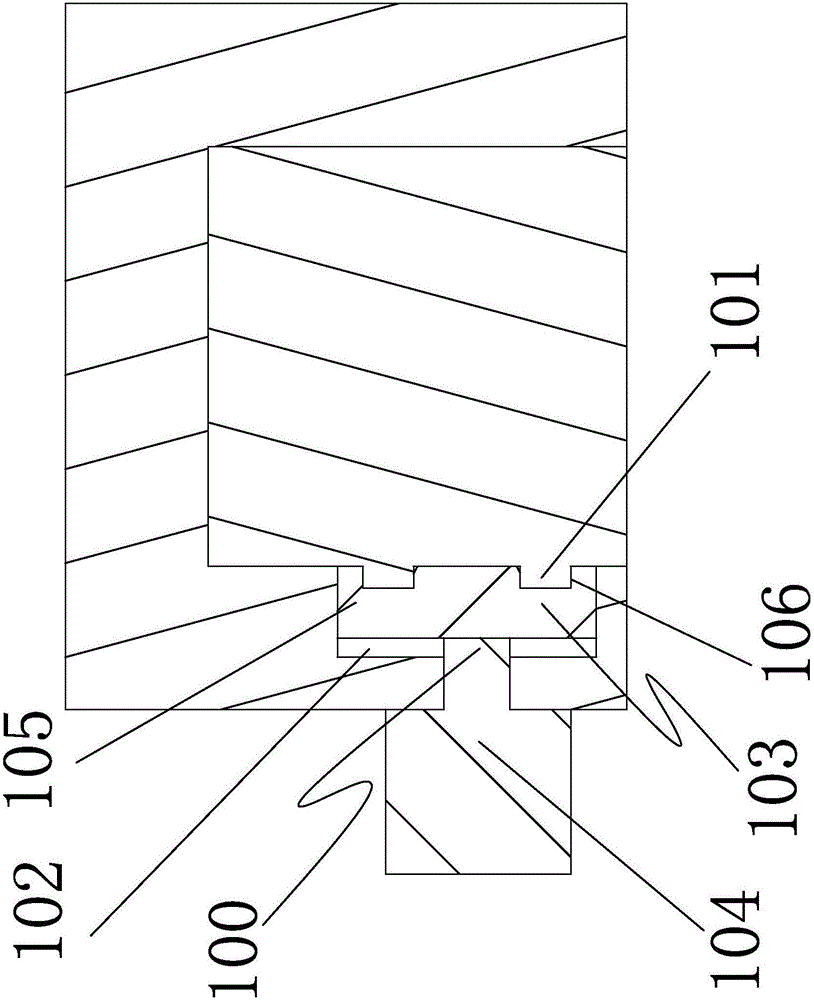

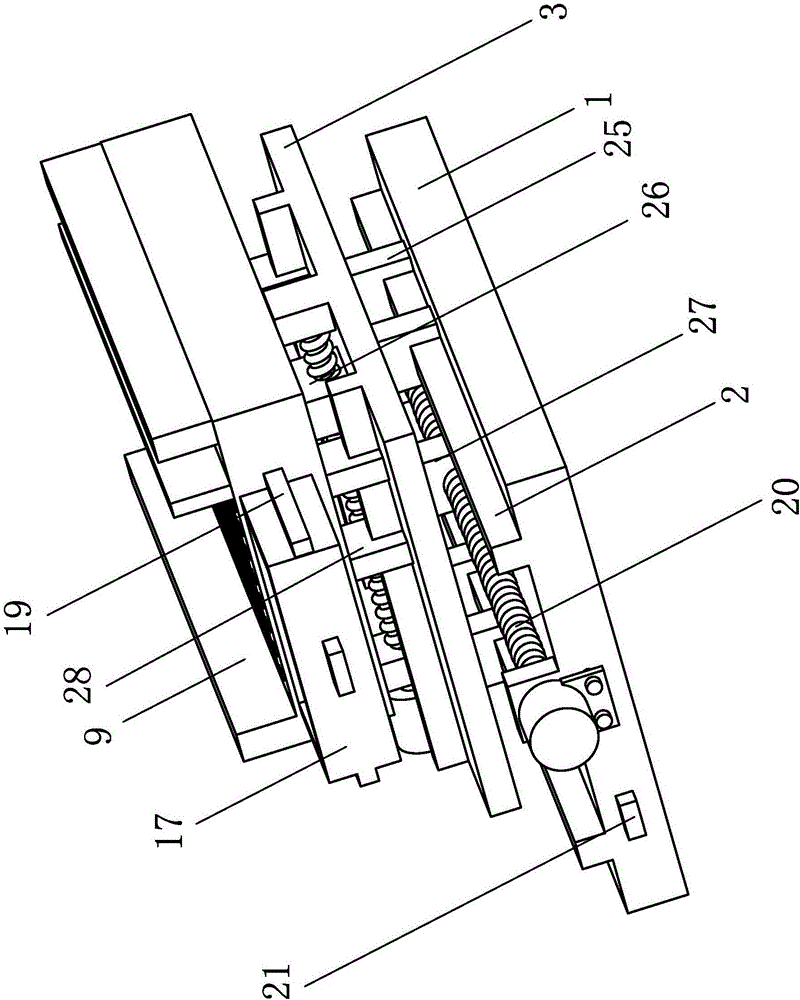

High-precision board drilling platform

A drilling platform and high-precision technology, which is applied in drilling machines, wood processing equipment, coatings, etc., can solve problems affecting processing accuracy, personnel damage, and reducing the number of qualified workpieces, so as to ensure processing accuracy, improve processing accuracy, and improve The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Antirust layer described in the present invention is made up of following components by weight:

[0029]

[0030]

[0031] Mix and stir graphene, strontium chromate, ammonium metaborate, chlorinated paraffin, and talcum powder evenly, and grind them in a conical grinder until the fineness is <50 μm, then add styrene-acrylic emulsion, dibutyl phthalate, and propylene glycol Dimethyl ether and other components can be obtained by ultrasonically dispersing evenly.

Embodiment 2

[0033] Antirust layer described in the present invention is made up of following components by weight:

[0034]

[0035]

[0036] Mix and stir graphene, strontium chromate, ammonium metaborate, chlorinated paraffin, and talcum powder evenly, and grind them in a conical grinder until the fineness is <50 μm, then add styrene-acrylic emulsion, dibutyl phthalate, and propylene glycol Dimethyl ether and other components can be obtained by ultrasonically dispersing evenly.

Embodiment 3

[0038] Antirust layer described in the present invention is made up of following components by weight:

[0039]

[0040]

[0041] Mix and stir graphene, strontium chromate, ammonium metaborate, chlorinated paraffin, and talcum powder evenly, and grind them in a conical grinder until the fineness is <50 μm, then add styrene-acrylic emulsion, dibutyl phthalate, and propylene glycol Dimethyl ether and other components can be obtained by ultrasonically dispersing evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com