Preparation method of superhydrophobic, oleophobic, bactericidal, flame-retardant and weather-resistant magnetic functional wood

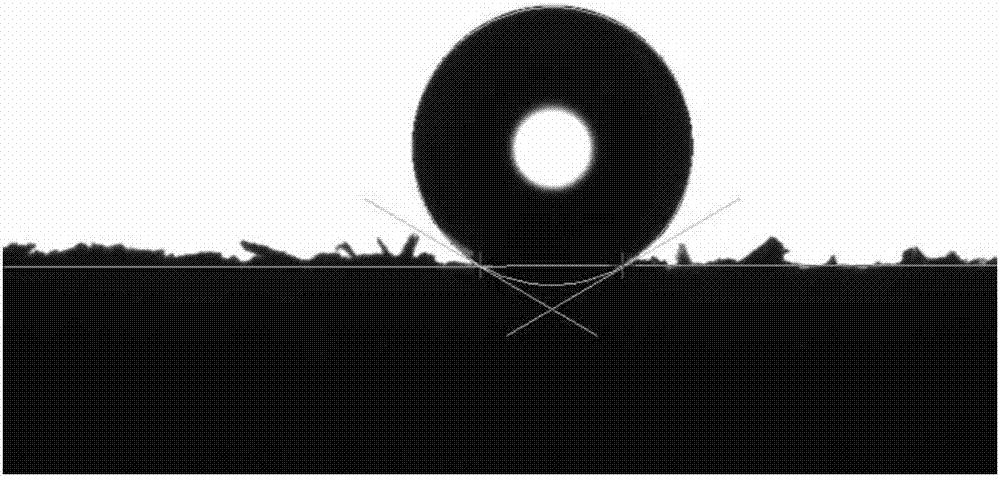

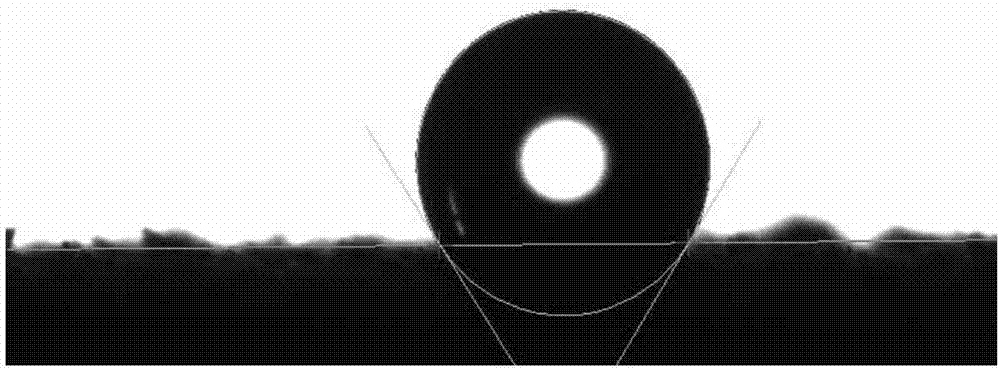

A super-hydrophobic and magnetic technology, used in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of poor resistance to loss, high cost, and high toxicity of modifiers, and achieve improved antiseptic and bactericidal performance, improved flame retardant performance, The effect of improved weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0033] Specific Embodiment 1: The preparation method of superhydrophobic, oleophobic, bactericidal, flame-retardant, weather-resistant and magnetic functional wood in this embodiment is carried out according to the following steps:

[0034] 1. Configuration of magnetic precursor liquid:

[0035] Weigh 1-5 parts of ferrous salt, 5-10 parts of ferric salt and 85-96 parts of deionized water according to the parts by mass, stir and dissolve to form a uniform solution, and obtain the magnetic precursor;

[0036] Two, wood magnetic treatment:

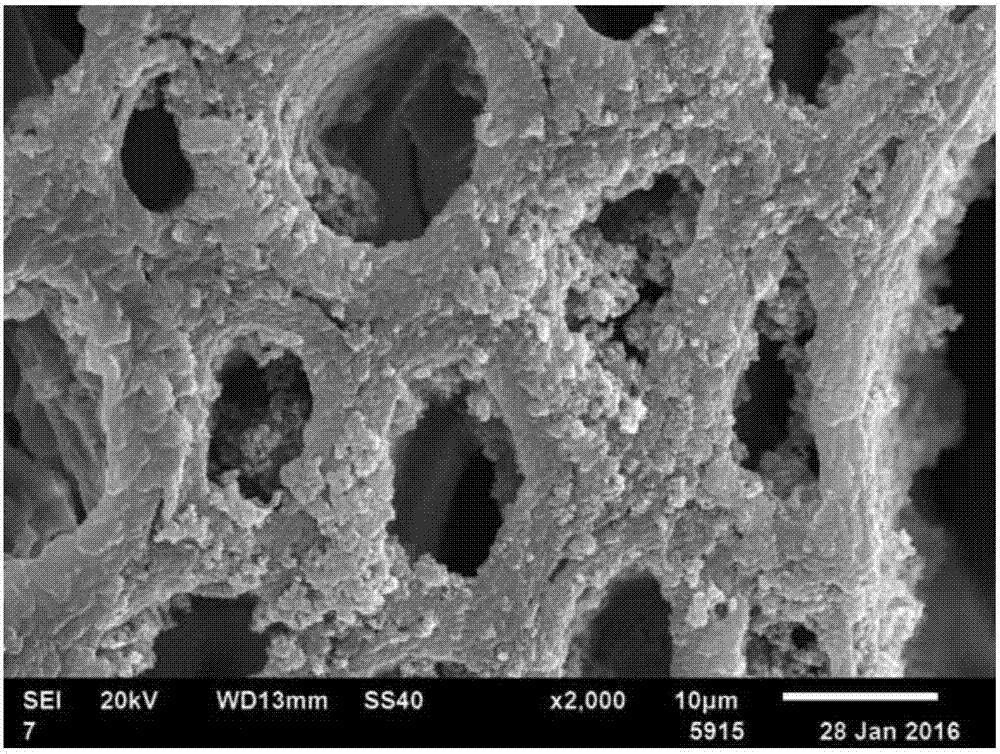

[0037] ①Add wood to the magnetic precursor solution obtained in step 1, and stir at room temperature for 1-5 hours; ②Add ammonia water dropwise to the magnetic precursor solution containing wood, adjust the pH to 9.5-10.5, and continue stirring for 1 hour; ③Take out the wood and place Wash it in distilled water until it is neutral, and leave it in the air for 1 hour at room temperature to complete the wood magnetic Fe 3 o 4 deal with;

[...

specific Embodiment approach 2

[0042] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the ferrous salt described in step one is FeCl 2 or FeCl 2 4H 2 O. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0043] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the ferric salt described in step one is FeCl 3or FeCl 3 ·6H 2 O. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com