Stone pattern glass plate and production process thereof

A production process and stone pattern technology, applied in the field of decorative materials, can solve the problems of not being realistic enough, poor decorative effect, and weak three-dimensional effect, and achieve the effect of strong three-dimensional effect, good decorative effect, and full color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

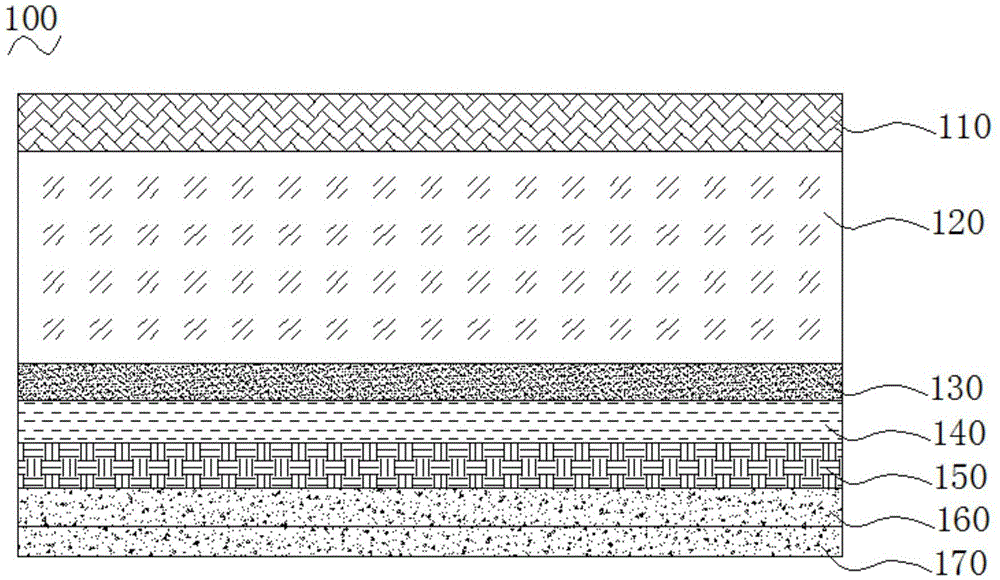

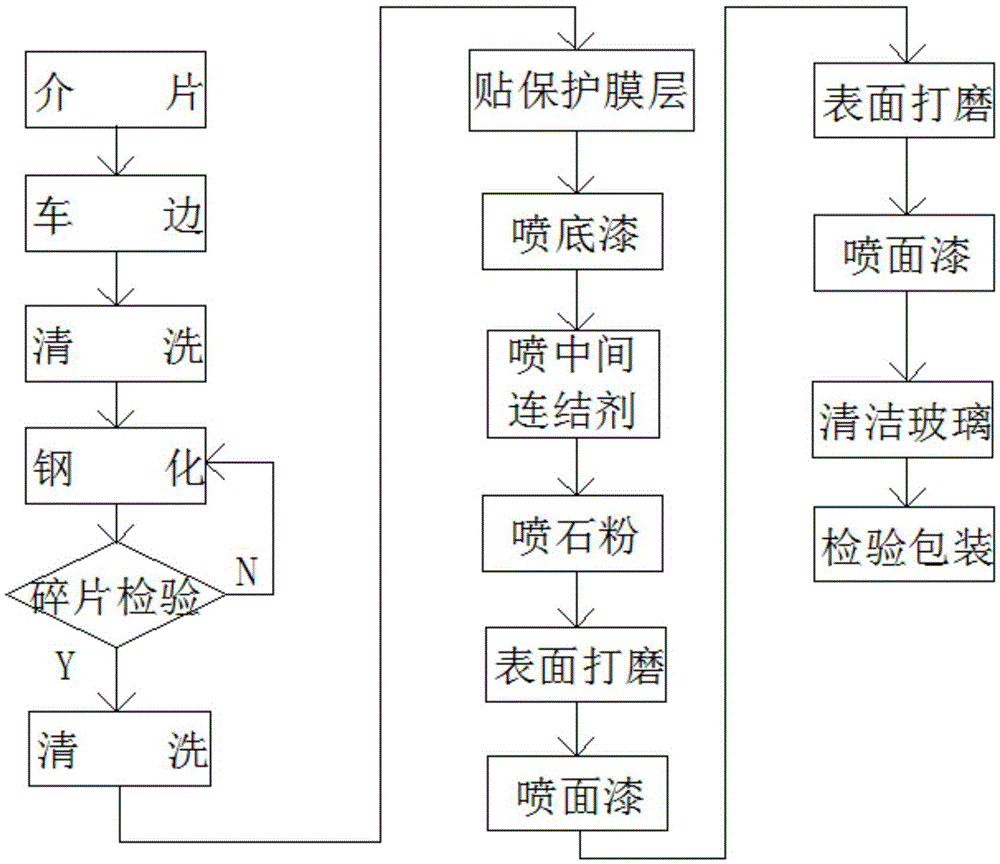

[0042] Such as figure 1 and figure 2 Shown are the structural schematic diagram and the production process flow chart of the stone-grained glass plate of the present invention, respectively.

[0043] The stone textured glass plate 100 includes a protective film layer 110, a tempered glass layer 120, a primer layer 130, an intermediate bonding agent layer 140, a stone powder layer 150, a first topcoat layer 160 and a second topcoat layer arranged in sequence from bottom to top 170, the protective film layer 110 is pasted on one side of the tempered glass layer 120, the primer layer 130 is sprayed and formed on the side of the tempered glass layer 120 away from the protective film layer 110, and the intermediate bonding agent layer 140 is formed on the paint of the primer layer 130 by spraying On the surface, the stone powder layer 150 is formed on the surface of the intermediate linking agent layer 140 by spraying, the first topcoat layer 160 is formed on the surface of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com