Large-scale closed fluidized storage and its application method

A closed and fluidized technology, which is applied in large-capacity bulk material storage, building types, loading/unloading, etc., can solve problems such as increased energy consumption, poor sealing level of storage, and decreased activity, so as to improve revenue Improve material efficiency, solve environmental problems, and reduce energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

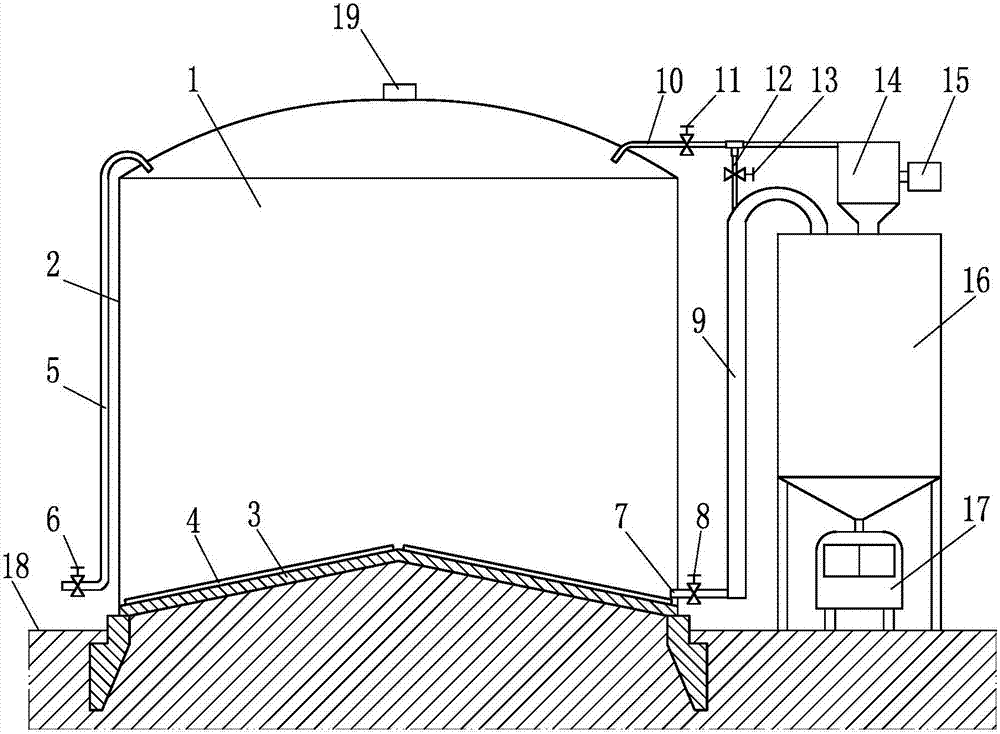

Embodiment 1

[0021] Such as figure 1 The large-scale closed fluidized storage system of the present invention shown in the present invention comprises a storage warehouse 1, a feed pipeline 5, a discharge pipeline 7, a material lifting device 9, a bulk storage 16 and a dust collection device, and the storage warehouse 1 It includes a storage body 2, a storage bottom structure and an activated gas source device 4 provided on the upper surface of the storage bottom structure, wherein the storage bottom structure directly falls on the ground 18, and the storage bottom structure includes a storage bottom 3 with a cone discharge slope , the activated gas source device 4 is arranged along the groove of the discharge slope, and the discharge pipeline 7 is connected to the storage warehouse 1 at the bottom of the side of the warehouse body 2; the dust collection device includes a dust collector 14 and an induced draft fan 15. The storage warehouse 1 is a closed structure; one end of the feed pipel...

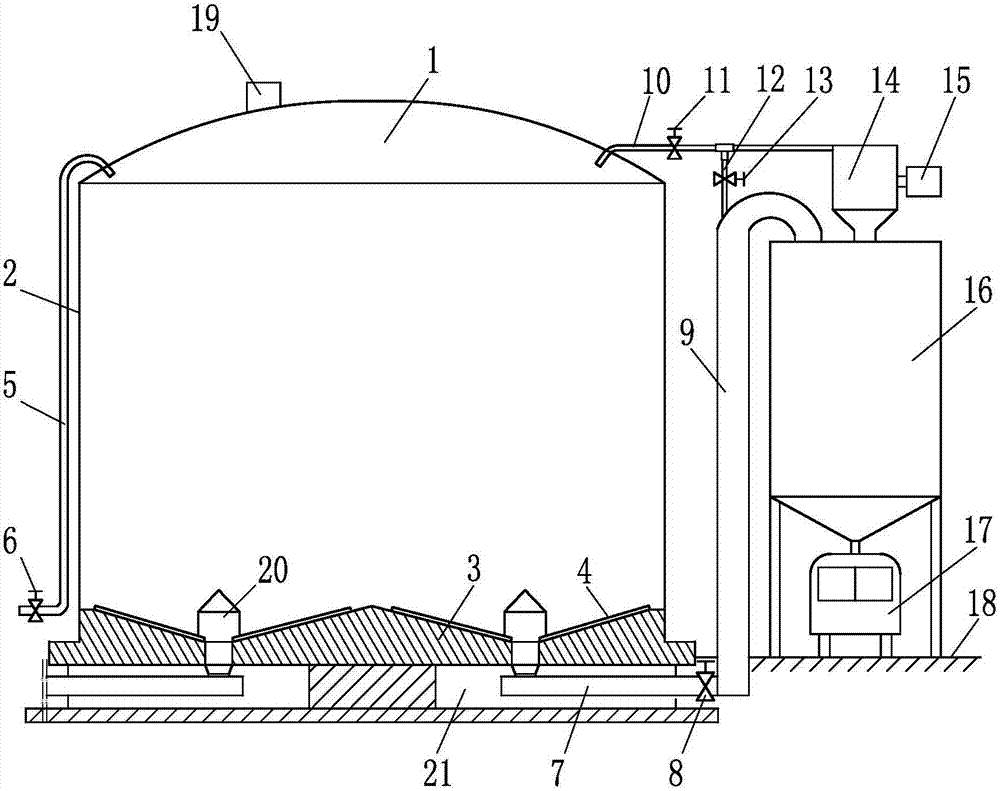

Embodiment 2

[0032] Such as figure 2 The difference between the large-scale closed fluidized storage system of the present invention shown in Embodiment 1 is that the storage bottom structure includes a discharge corridor 21 and a storage bottom 3 including a plurality of cone discharge slopes, and the activated gas source device 4 is along the The groove of the discharge slope is set, and the discharge pipeline 7 is connected to the decompression discharge device 20 in the storage warehouse at the bottom of the storage warehouse.

[0033] The application method of the large-scale closed fluidized storage system of the present invention described in this example and its advantages over the prior art are basically the same as those in Embodiment 1, and will not be described again here.

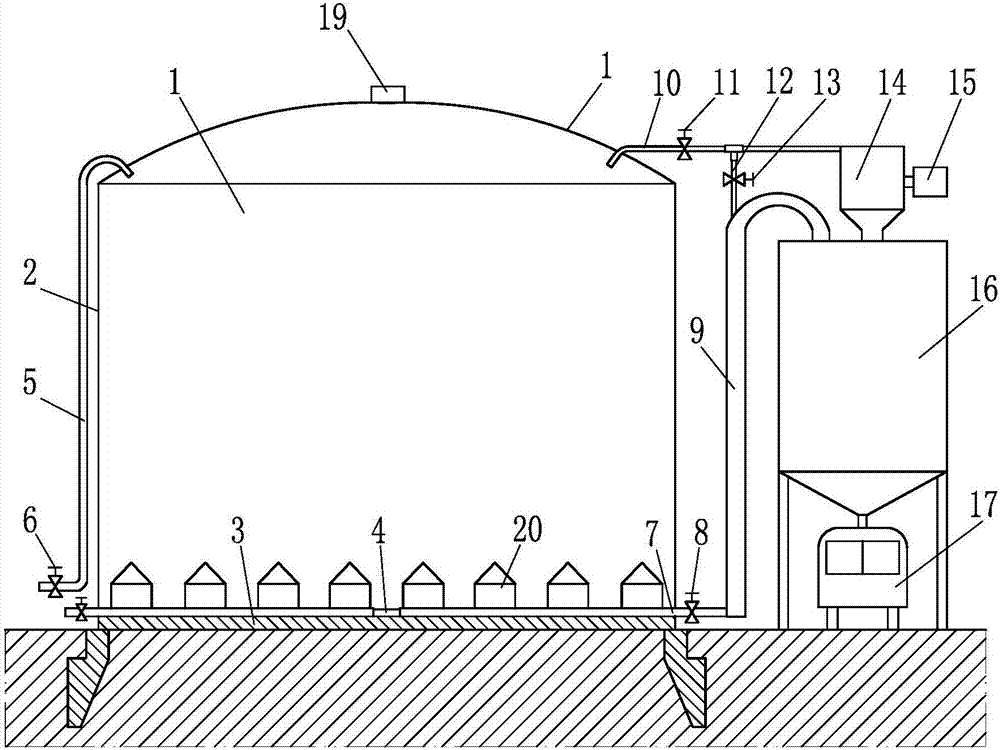

Embodiment 3

[0035] Such as image 3 The difference between the large-scale closed fluidized storage system of the present invention and the second embodiment is that the storage bottom structure includes a flat storage bottom 3 directly on the ground, and the activated gas source device 4 is arranged on the upper surface of the flat storage bottom 3. The discharge pipeline 7 is connected to the storage warehouse 1 through a decompression discharge device 20 at the lower part of the side of the storage body.

[0036] The application method of the large-scale closed fluidized storage system of the present invention described in this example and its advantages over the prior art are basically the same as those in Embodiment 1, and will not be described again here. compared to figure 1 and figure 2 As shown in the large-scale closed fluidized storage system of the present invention, the structure of the storage bottom 3 in the technical solution described in this example is simpler, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com