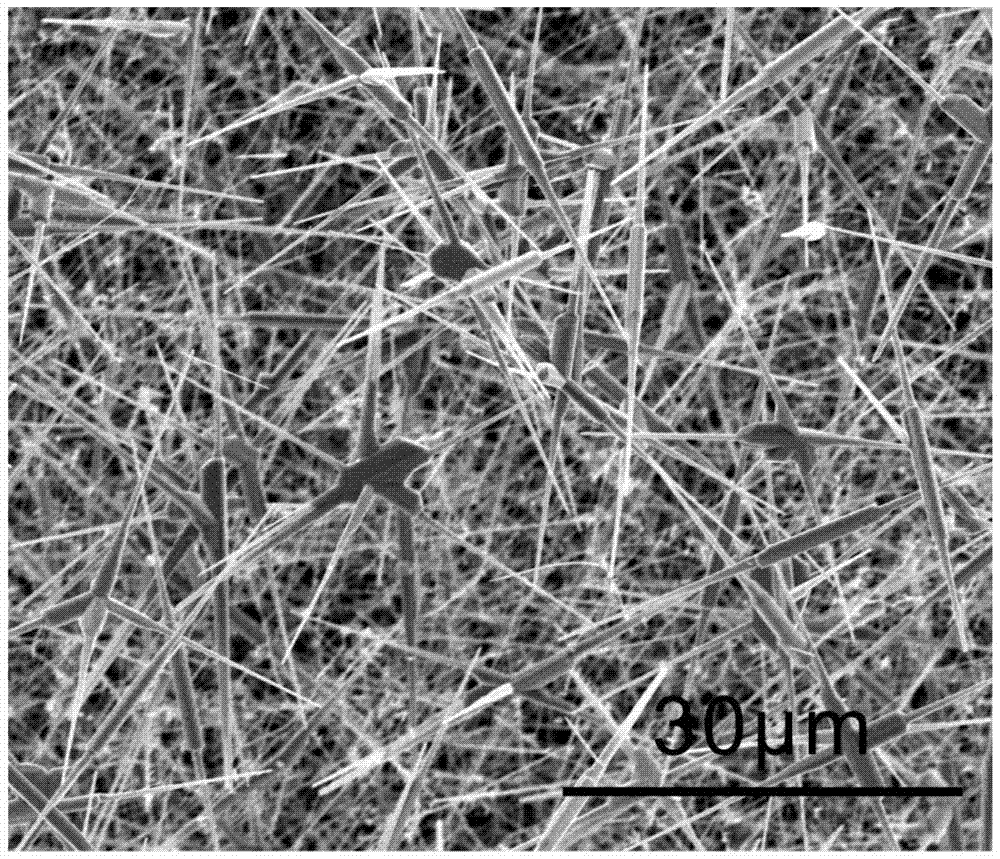

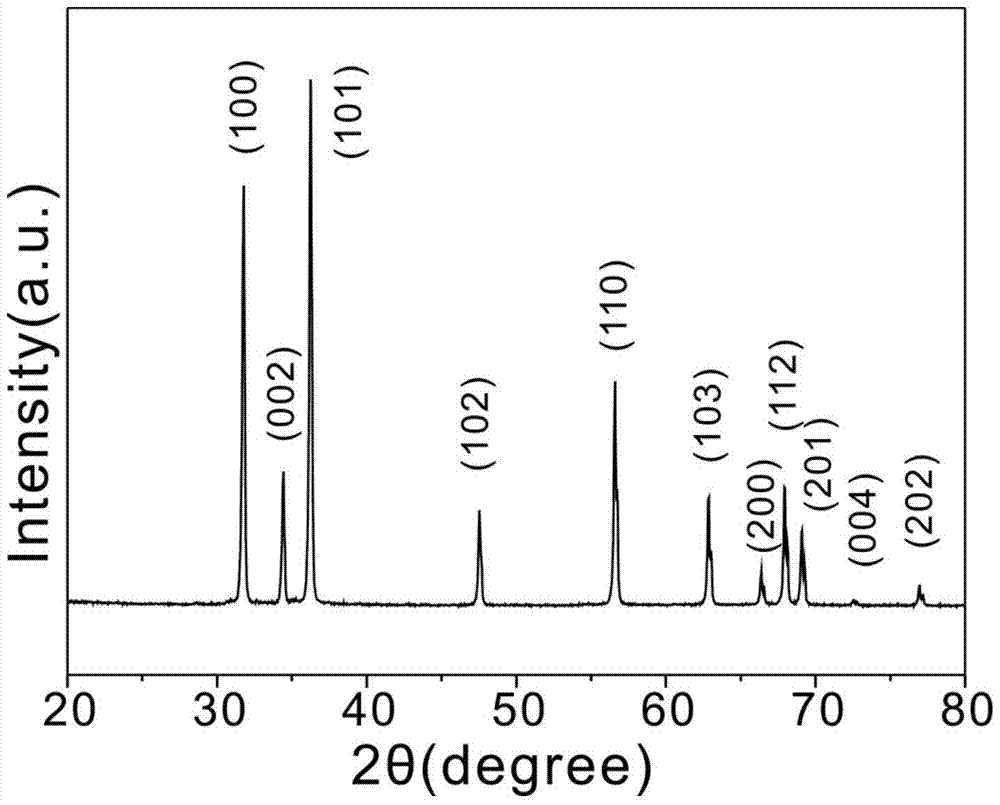

Nano-zinc oxide with planar hierarchical structure and preparation method thereof

A technology of nano-zinc oxide and hierarchical structure, applied in the field of nano-materials, can solve the problems of expensive equipment and inability to be realized by research groups, and achieve the effects of good uniformity, easy control of the preparation process and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of a kind of planar hierarchical structure nano-zinc oxide that the present invention proposes comprises the following steps:

[0024] a. Grinding 0.2g of zinc oxide powder to obtain the first material;

[0025] b. Introduce nitrogen into the reaction vessel for 40 minutes at a rate of 10 L / min, then preheat the reaction vessel at 650°C and keep warm for 10 minutes;

[0026] c. Put the first material in the preheated reaction vessel, raise the temperature to 750°C at a heating rate of 10°C / min, keep it warm for 10 minutes, raise the temperature to 850°C at a heating rate of 10°C / min, keep it warm for 10 minutes, and keep it at 25 The heating rate of ℃ / min is raised to 950 ℃, and the temperature is kept for 30 minutes. Nitrogen gas is introduced at a rate of 3 L / min during the heating process and the holding process, and then cooled to room temperature at a cooling rate of 10 ℃ / min to obtain a planar hierarchical structure nano-zinc oxide , Nitrog...

Embodiment 2

[0030] The preparation method of a kind of planar hierarchical structure nano-zinc oxide that the present invention proposes comprises the following steps:

[0031] a. Grinding 0.1g of zinc oxide powder to obtain the first material;

[0032] b. Feed nitrogen into the reaction vessel for 30 minutes at a rate of 15 L / min, then preheat the reaction vessel at a temperature of 600° C. and keep it warm for 5 minutes;

[0033] c. Put the first material in the preheated reaction vessel, raise the temperature to 700°C at a heating rate of 5°C / min, keep it warm for 5min, raise the temperature to 800°C at a heating rate of 5°C / min, keep it warm for 5min, and keep it for 20 The heating rate of ℃ / min is raised to 900 ℃, and the temperature is kept for 20 minutes. Nitrogen gas is introduced at a rate of 4 L / min during the heating process and the holding process, and then cooled to room temperature at a cooling rate of 5 ℃ / min to obtain a planar hierarchical structure nano-zinc oxide , Nitr...

Embodiment 3

[0035] The preparation method of a kind of planar hierarchical structure nano-zinc oxide that the present invention proposes comprises the following steps:

[0036] a. Grinding the zinc oxide powder to obtain the first material;

[0037] b. Feed nitrogen into the reaction vessel for 35 minutes at a rate of 12 L / min, then preheat the reaction vessel at 630° C. and keep it warm for 8 minutes;

[0038] c. Put the first material in the preheated reaction vessel, raise the temperature to 650°C at a heating rate of 8°C / min, keep it warm for 8 minutes, raise the temperature to 750°C at a heating rate of 8°C / min, keep it warm for 8 minutes, and heat it for 30 minutes. The heating rate of ℃ / min is raised to 850 ℃, and the temperature is maintained for 15 minutes. Nitrogen gas is introduced at a rate of 2 L / min during the heating process and the heat preservation process, and then cooled to room temperature at a cooling rate of 8 ℃ / min to obtain a planar hierarchical structure nano-zinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com