Technique for separating and recovering phenol-isooctanol mixture on monophenyldiisooctyl phosphite production device

A phenylenedi-isooctyl phosphite and production device technology, applied in the separation/purification of hydroxyl compounds, preparation of organic compounds, compounds of Group 5/15 elements of the periodic table, etc., can solve the problem of low price and mixture Sales difficulties and other issues, to achieve the effect of improving comprehensive benefits, increasing the value of by-products, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A separation and recovery process of phenol and isooctyl alcohol mixture on a phenylenedi-isooctyl phosphite production device, the process is as follows:

[0024] (1) Nitrogen purging: After decompressing nitrogen, adjust it to a slight positive pressure, then pass it into the entire system, blow out the air in the entire system, and ensure that the system pressure is 101.53Pa during the entire process, and the system includes crystallization device, buffer tank, liquid storage tank, product tank and several connecting pipelines;

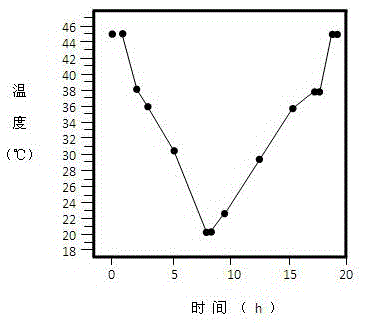

[0025] (2) Preheating the crystallizer: Open the hot water tank to make hot water, then pass the hot water into the shell side of the crystallizer, turn on the circulating water pump on the shell side of the crystallizer, circulate the hot water, and raise the temperature of the crystallizer to 45°C;

[0026] (3) Feed: Heat 1kg of the mixture of phenol and isooctyl alcohol to 45°C, then transfer it to the crystallizer after step (2) through ...

Embodiment 2

[0035] A separation and recovery process of phenol and isooctyl alcohol mixture on a phenylenedi-isooctyl phosphite production device, the process is as follows:

[0036] (1) Nitrogen purging: adjust the nitrogen pressure to a slight positive pressure after decompression, and then pass it into the entire system to blow out the air in the entire system, and ensure that the system pressure is 101.68Pa during the entire process. The system includes crystallization device, buffer tank, liquid storage tank, product tank and several connecting pipelines;

[0037] (2) Preheating the crystallizer: Open the hot water tank to make hot water, then pass the hot water into the shell side of the crystallizer, turn on the circulating water pump on the shell side of the crystallizer, circulate the hot water, and raise the temperature of the crystallizer to 45°C;

[0038] (3) Feed: Heat 1.5kg of the mixture of phenol and isooctyl alcohol to 45°C, then transport it to the crystallizer after ste...

Embodiment 3

[0047] A separation and recovery process of phenol and isooctyl alcohol mixture on a phenylenedi-isooctyl phosphite production device, the process is as follows:

[0048] (1) Nitrogen purging: After decompressing nitrogen, adjust it to a slight positive pressure, then pass it into the entire system, blow out the air in the entire system, and ensure that the system pressure is 101.71Pa during the entire process. The system includes crystallization device, buffer tank, liquid storage tank, product tank and several connecting pipelines;

[0049] (2) Preheating the crystallizer: Open the hot water tank to make hot water, then pass the hot water into the shell side of the crystallizer, turn on the circulating water pump on the shell side of the crystallizer, circulate the hot water, and raise the temperature of the crystallizer to 45°C;

[0050] (3) Feed: Heat 2 kg of the mixture of phenol and isooctyl alcohol to 45°C, then transfer it to the crystallizer after step (2) through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com