Method for preparing polyether modified HMDI waterborne polyurethane curing agent

A water-based polyurethane, polyether modification technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of difficult to promote water-based paint, high cost, high price, etc., achieve high fullness, good yellowing resistance , The effect of strong pollution resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

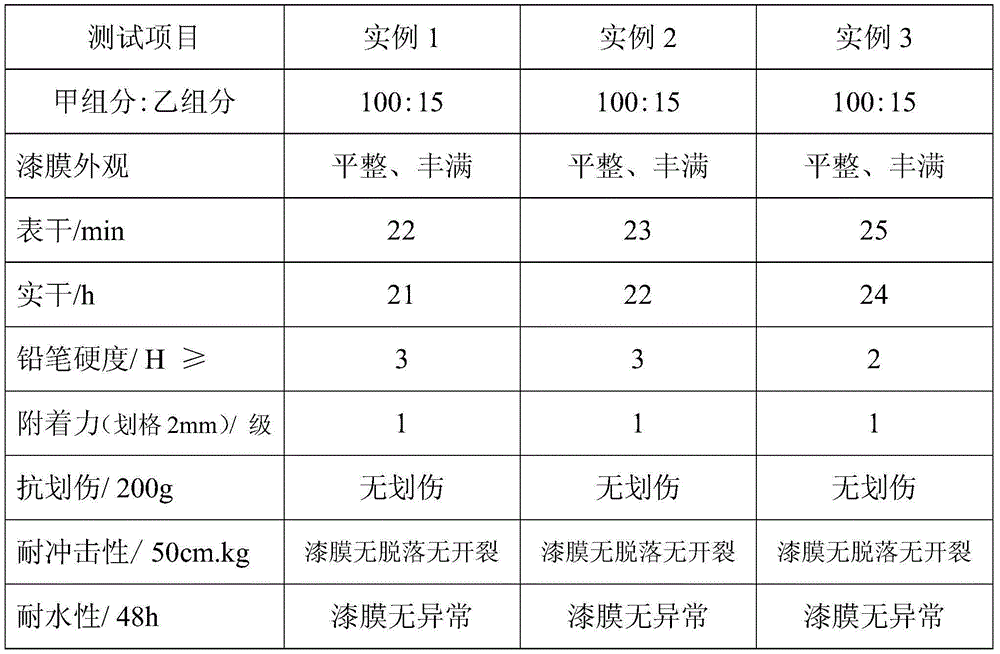

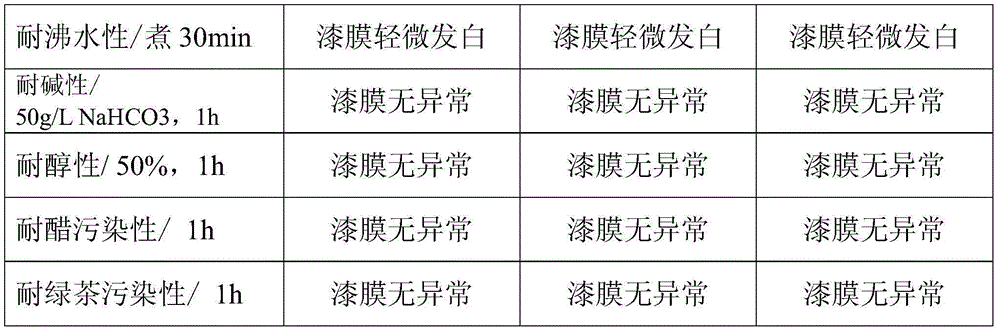

Embodiment 1

[0010] Add metered 11 parts of polyethylene glycol monobutyl ether (Mr1000) in the dripping kettle, after vacuum heating and dehydration for 2h, feed N 2 Seal it for later use; in the synthesis kettle, add 20 parts of propylene glycol methyl ether acetate, and after vacuum heating and dehydration for 2h, feed into N 2 , adding 69 parts of H 12 After MDI is heated and dissolved, add polyethylene glycol monobutyl ether dropwise, keep a constant temperature reaction at 75-80°C for 3-4hrs, and add 2,4,6-tris(dimethylaminomethyl) when the NCO content is close to the calculated value base) 0.2 part of phenol, cooled and filtered to obtain a polyether modified H 12 MDI water-based polyurethane curing agent.

Embodiment 2

[0012] Add metered 8 parts of polyethylene glycol monobutyl ether (Mr1000) in the dripping kettle, after vacuum heating and dehydration for 2h, pass into N 2 It is sealed for later use; in the synthesis kettle, add 20 parts of propylene glycol methyl ether acetate and carry out vacuum heating and dehydration for 2h, feed into N 2 , adding 72 parts of H 6 After the MDI is heated and dissolved, add polyethylene glycol monobutyl ether dropwise, keep a constant temperature reaction at 70-80°C for 3-4hrs, and add 2,4,6-tris(dimethylaminomethyl) when the NCO content is close to the calculated value Base) 0.2 part of phenol, cooled and filtered to obtain a polyether modified H with 80% solid content and 17.6% NCO 6 MDI water-based polyurethane curing agent.

Embodiment 3

[0014] Add metered 10 parts of polyethylene glycol (Mr1000) in the dripping kettle, after vacuum heating and dehydration for 2h, feed N 2 Seal it for later use; in the synthesis kettle, add 20 parts of diethylene glycol ethyl ether acetate and carry out vacuum heating and dehydration for 2 hours, then pass into N 2 , adding 70 parts of H 12 After MDI is heated and dissolved, add polyethylene glycol monobutyl ether dropwise, keep a constant temperature reaction at 75-80°C for 3-4hrs, and add 2,4,6-tris(dimethylaminomethyl) when the NCO content is close to the calculated value base) 0.2 part of phenol, cooled and filtered to obtain a polyether modified H with 80% solid content and 16.4% NCO 12 MDI water-based polyurethane curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com