Steel material for graphitization and graphite steel with excellent machinability and cold forging characteristic

A technology of graphitization and graphite steel, applied in the field of graphite steel, can solve the problems of shortened tool life, low cold forgeability, and not being popularized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

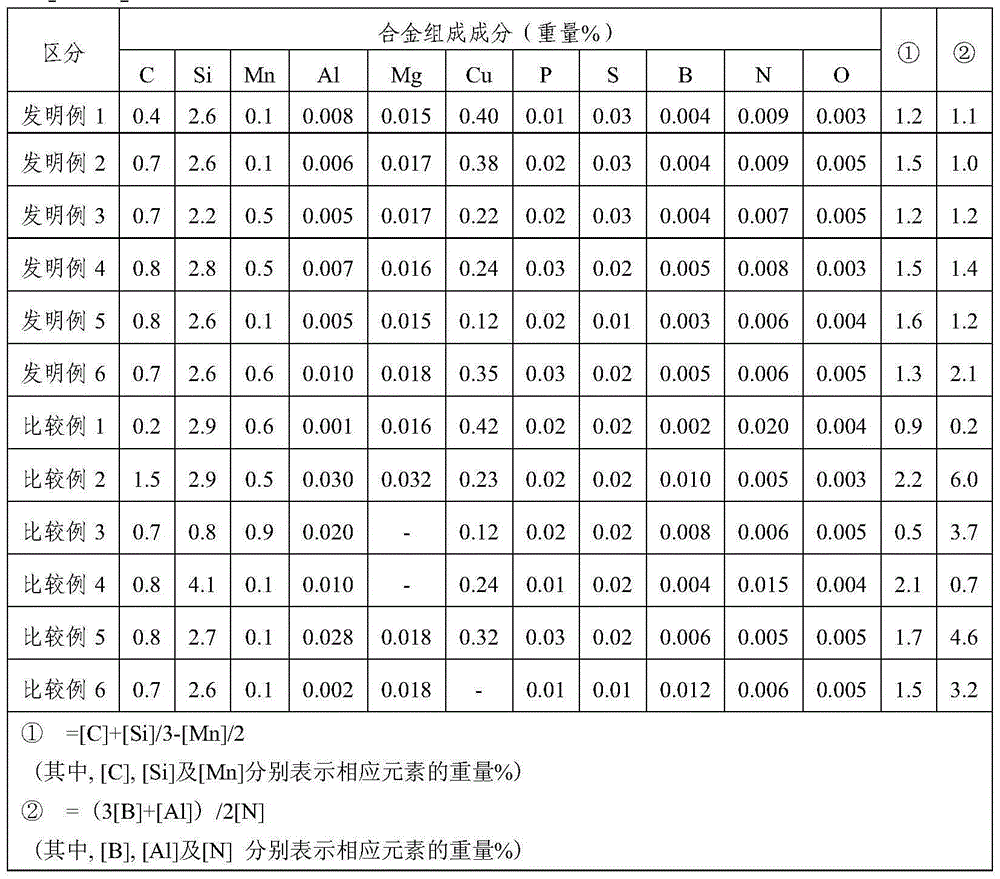

[0016] Hereinafter, the steel material for graphitization heat treatment in one aspect of the present invention will be described in detail. First, the alloy composition and component range of the steel material will be described in detail.

[0017] Carbon (C): 0.30~0.80% by weight

[0018] Carbon is an essential element for the formation of graphite particles. When the carbon content is less than 0.30% by weight, the effect of improving the machinability is insufficient. On the contrary, when the carbon content is too large, graphite particles may be roughly precipitated, which may reduce cold forgeability. Therefore, the upper limit of the carbon content is preferably 0.80% by weight, and more preferably 0.70% by weight.

[0019] Silicon (Si): 2.0~3.0% by weight

[0020] Silicon is a necessary component as a deoxidizer when manufacturing steel ingots. It is a graphitization promoting element that precipitates by destabilizing iron carbide in steel and turning carbon into graphite,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com