Expanded-base combination end pile bearing foundation

An end-bearing pile and foundation technology, applied in the direction of foundation structure engineering, sheet pile wall, construction, etc., can solve the problems that the cost prefabricated piles cannot be well adapted, the strength of prefabricated piles is redundant and wasteful, and the prefabricated piles are not fully utilized. Solve the effect of softening in water, increasing the stress surface of the pile end, and improving the strength performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

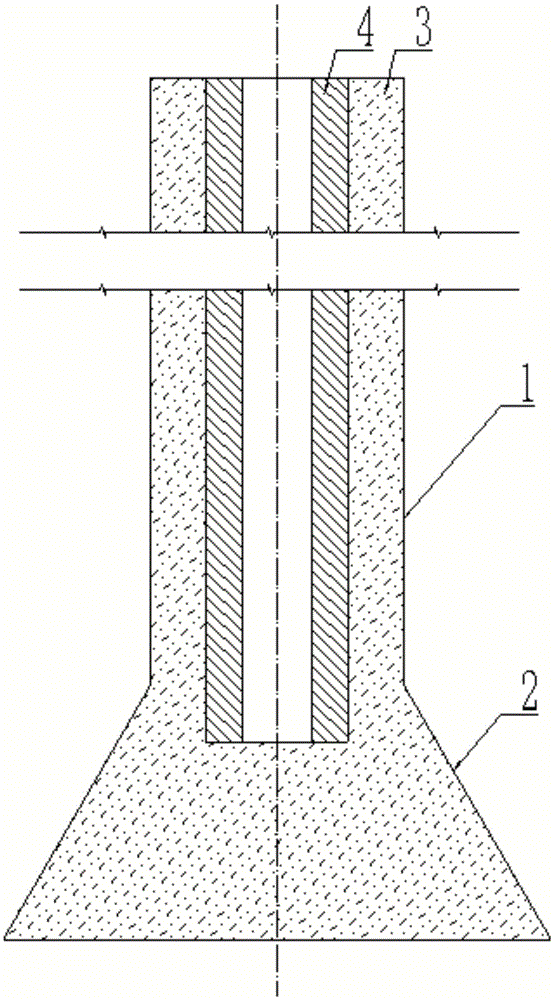

[0046] According to the geological and construction conditions, a rotary drilling rig is used to drill holes with a diameter of 600mm at the pile forming position to a depth of 4m into the bearing rock formation, and the drilling powder is discharged in the form of dry discharge;

[0047] Replace or adjust the drill bit with progressive reaming function to ream the bottom of the pile hole to form a conical pile bottom hole with an angle of 45° between the side and the bottom surface and a thickness of 600mm. After that, clean the hole with a negative pressure dust suction device;

[0048] After the hole cleaning is completed, inject mortar with a strength grade of M10 into the hole until the volume of the remaining pile hole is equal to the volume of the prefabricated pile;

[0049] After the pouring is completed and before the initial setting of the mortar, the PC pipe pile with a diameter of 400mm is implanted in place with a spreader, so that the bottom surface of the prefab...

Embodiment 2

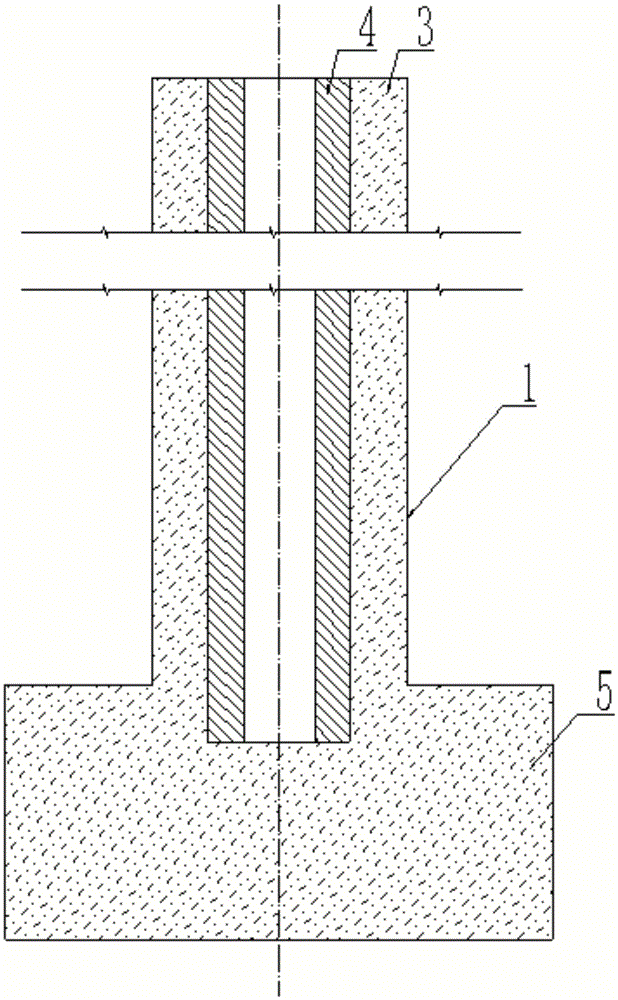

[0051] According to the geological and construction conditions, the rotary drilling rig is used to drill the mud retaining wall at the pile forming position, and the hole is drilled with a diameter of 800mm to a depth of 6m in the bearing rock formation;

[0052] Replace or adjust the reaming drill bit to ream the bottom of the pile hole to form a cylindrical pile bottom hole with a diameter of 1200mm and a thickness of 800mm.

[0053] Inject concrete with a strength grade of C30 from the bottom of the hole, and discharge the retaining mud at the same time;

[0054] After the pouring is completed and before the initial setting of the concrete, the PHS prestressed concrete hollow square pile with a side length of 500mm is implanted in place with a spreader, so that the distance between the bottom surface of the prefabricated pile and the bottom of the hole is 800mm, and the deviation between the pile axis and the hole axis is less than 40mm , fix the prefabricated pile until th...

Embodiment 3

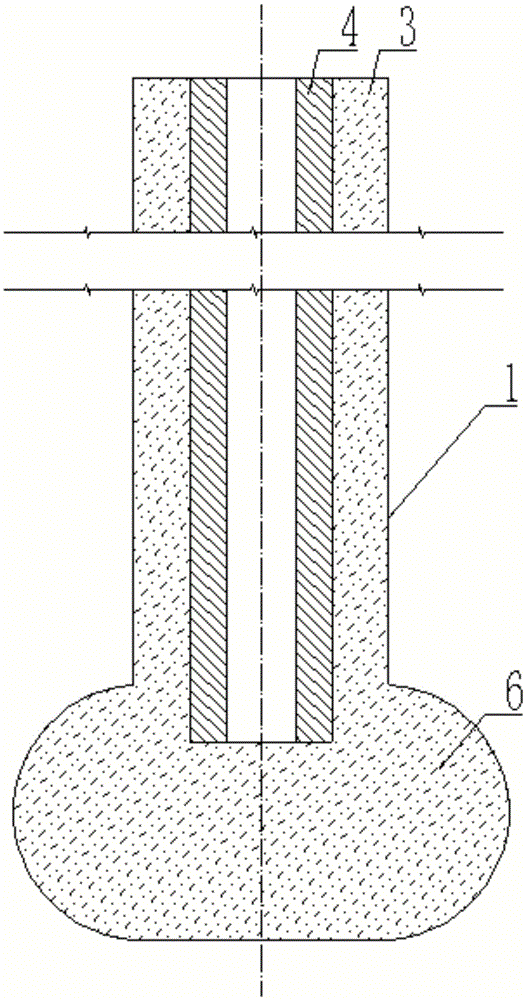

[0056] According to the geological and construction conditions, a down-the-hole drilling rig is used to drill holes with a diameter of 1000mm at the pile forming position to a depth of 8m into the bearing rock formation, and the drilling powder is discharged in the form of dry discharge;

[0057] Replace or adjust the reaming drill bit, and ream the pile holes that go deep into the bearing rock formation to form a pumpkin-shaped pile bottom hole with a maximum diameter of 1600mm and a thickness of 1000mm.

[0058] Before pulling out the drill bit, inject 1:0.5 high-fluidity cement slurry mixed with water reducing agent, start the drill bit, fully stir the cement slurry and pile bottom sediment, pull out the drill bit, and continue to inject cement slurry until the volume of the remaining pile hole is equal to the volume of the prefabricated pile .

[0059] After the pouring is completed and before the initial setting of the cement slurry, use the spreader to implant the PHC pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com