Method for forming holes with rock-socketed piles in karst areas and recyclable ultra-long steel casings

A technology of steel casing and rock-socketed piles, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve problems such as endangering the safety of construction personnel, machinery and equipment, preventing the collapse of the hole wall, water leakage, slurry leakage, etc. Conducive to the effect of vibrating compaction, maintaining stability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

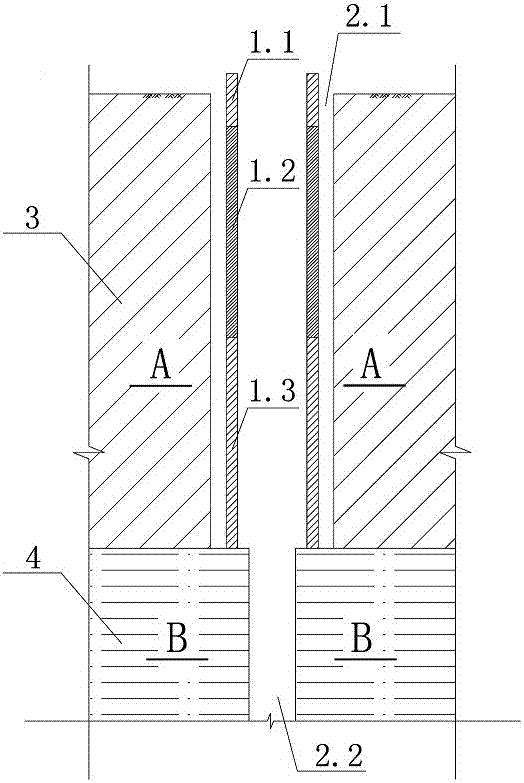

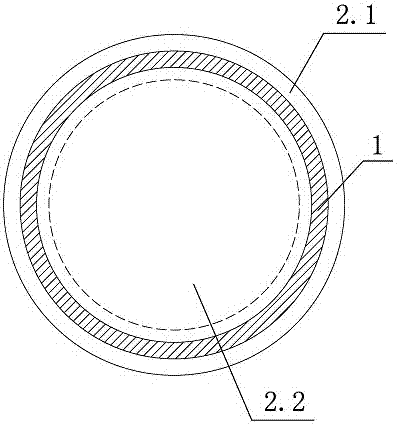

[0012] see Figure 1-3 , the present invention comprises the following steps, first adopting the measures of mud retaining wall, carrying out the pile hole 2.1 construction of the overlying soil layer on the rock-socketed pile, secondly hanging the recyclable super-long steel casing 1, finally using the percussion drilling machine to break through the karst roof, and carrying out the rock-socketed pile 2.2 Construction of bedrock pile holes.

[0013] The recyclable super-long steel casing is composed of the upper steel casing 1.1, the middle steel casing 1.2 and the lower steel casing 1.3; the total length of the recyclable super-long steel casing is greater than the depth of the overlying soil layer 3, and the inner diameter is larger Bedrock pile hole 2.2, outer diameter smaller than pile hole 2.1 in the overlying soil layer, the bottom of the lower steel casing is flush with the top surface of the underlying bedrock 4, and the top of the upper steel casing is higher than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com