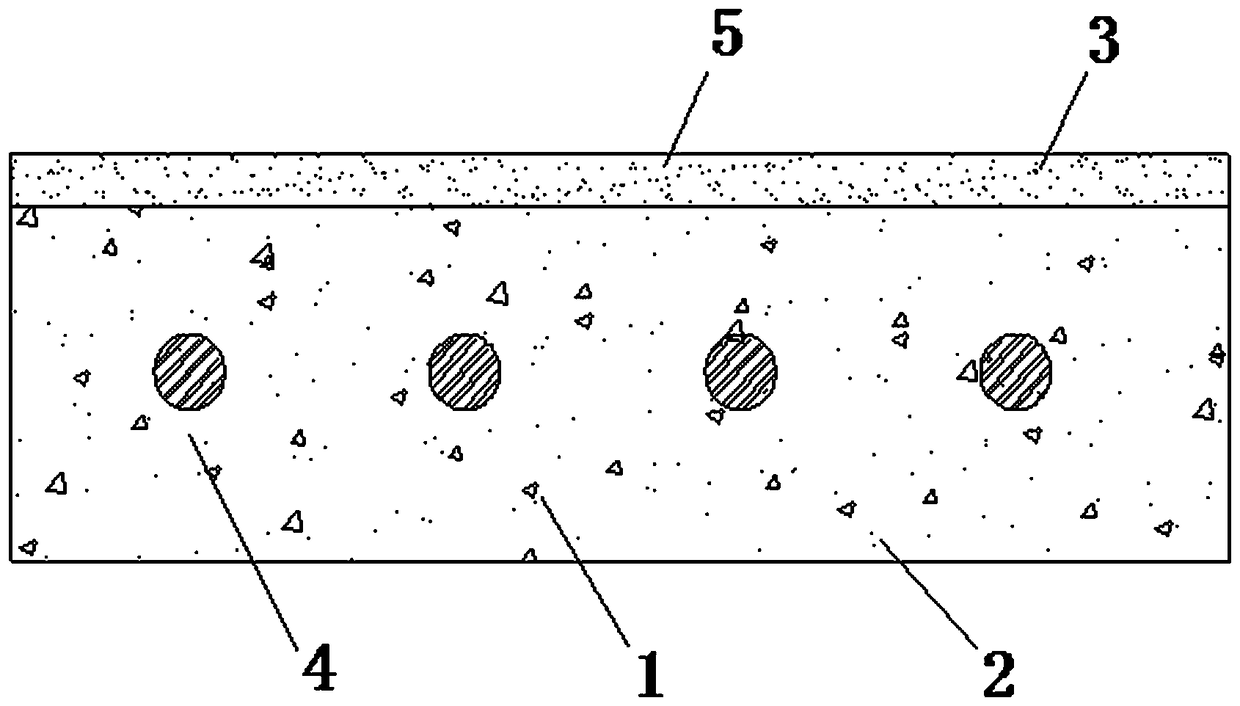

Preparation and casting construction method of high-strength anti-scouring abrasion type concrete with surface reinforcing layer

A technology of surface strengthening layer and preparation method, which is applied in construction, building structure, processing of building materials, etc., can solve the problems of decreased hardness of surface material, decreased anti-abrasion performance, difficult pouring and compaction, etc., and achieves fluidity and viscosity. Moderate cohesion, improving overall abrasion resistance, ensuring hardness and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 ready-mixed dry powder concrete

[0026] Select sand and stone aggregates according to the requirements. After finding the source of the materials, take samples for testing to judge whether they meet the requirements of "Code for Construction of Hydraulic Concrete" 5144 for concrete coarse aggregates and fine aggregates, and judge whether they meet the requirements of hardness and mud content. Quantity and particle size requirements. Aggregate that meets the requirements enters the ready-mixing yard for storage. Aggregate that meets these requirements is hard, clean, and rounded in shape. If it is just that the mud content is too large and does not meet the requirements, it can be washed to remove the mud if conditions permit. Aggregate should be dried.

[0027] For cement, choose ordinary Portland 52.5 grade cement, and you can also add an appropriate amount of fly ash, silica fume and other admixtures as cementitious materials. Choose a powdery high-p...

Embodiment 2

[0035] Example 2 ready-mixed concrete

[0036] If sand and stone sources that meet the requirements can be found near the construction site, there is no need to carry out pre-mixing of dry powder concrete, and the concrete can be directly mixed on site. Its basic steps are:

[0037] Survey the stockyard, carry out necessary mining, crushing, screening, washing, dehydration and other treatments on the aggregate, test its various indicators, and if it meets the requirements, store it in a suitable silo.

[0038] Select other raw materials such as cement, water reducer and hard abrasives that meet the requirements.

[0039] According to the requirements of water-cement ratio, strength grade, slump and aggregate volume ratio, etc., the mix ratio design is carried out to determine the material consumption of each square concrete.

[0040] When pouring concrete, mix the ingredients according to the mix ratio, mix them, put them in the warehouse, and vibrate them for compaction. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com