Pressure Balance Valve Common Rail Injector

A common rail injector and balancing valve technology, which is applied to machines/engines, fuel injection devices, engine components, etc., can solve the problems of reducing the area, increasing the multiple injection capability, affecting the injection rate of the injector, and achieving Increased fuel flow area, optimized fuel injection rate, accurate and reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the present invention, the implementation manners of the present invention will be explained in detail below in conjunction with the accompanying drawings.

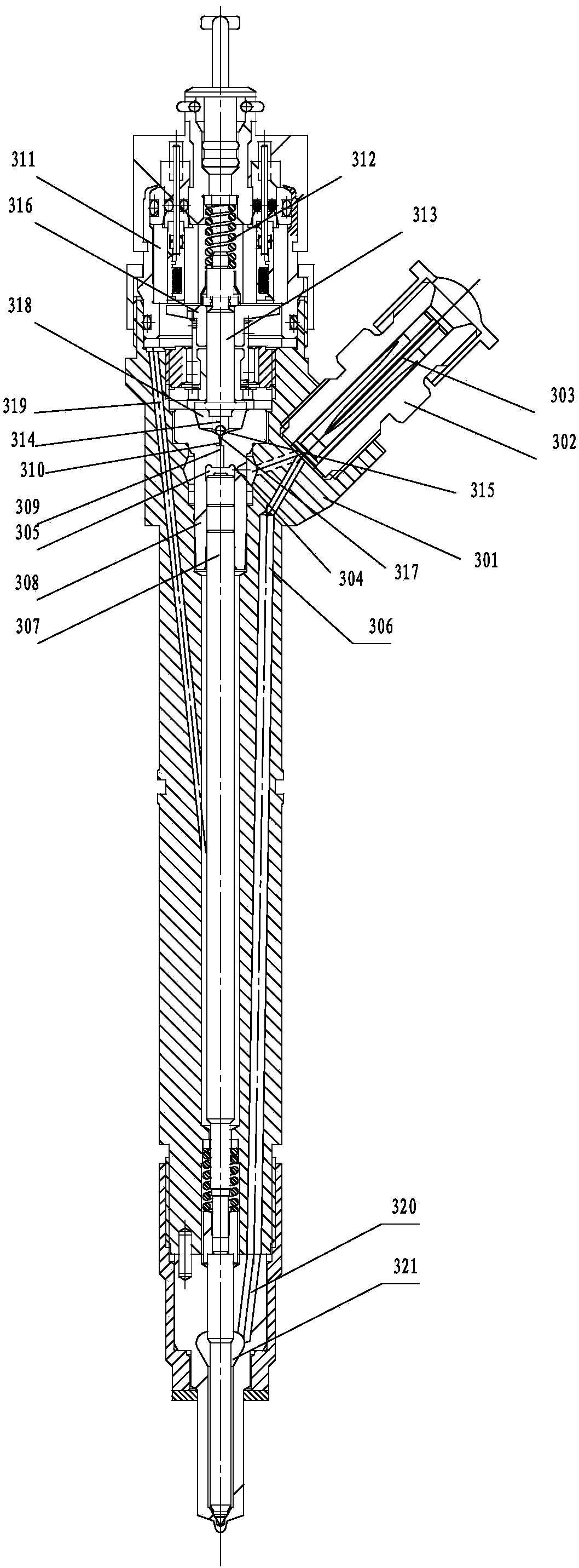

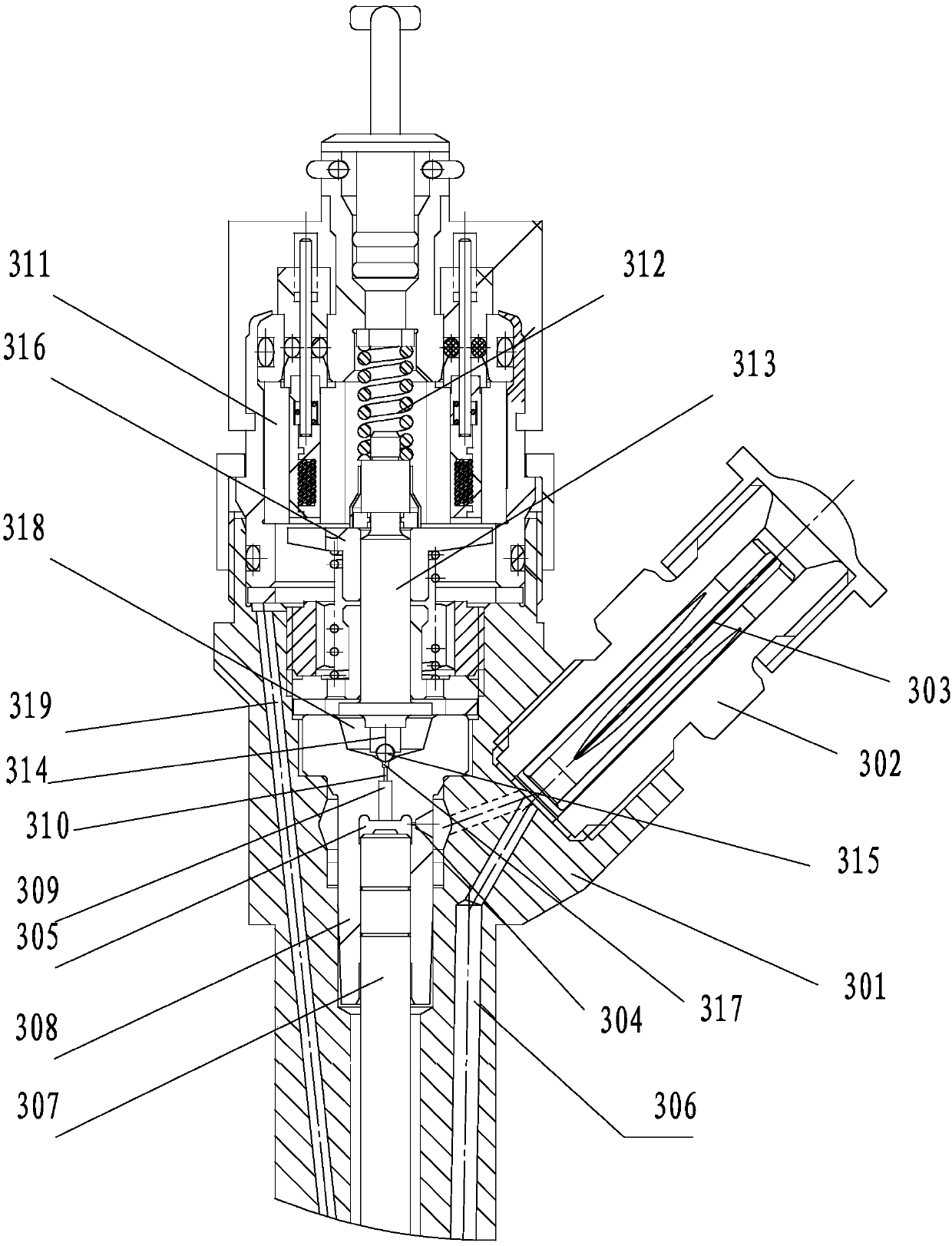

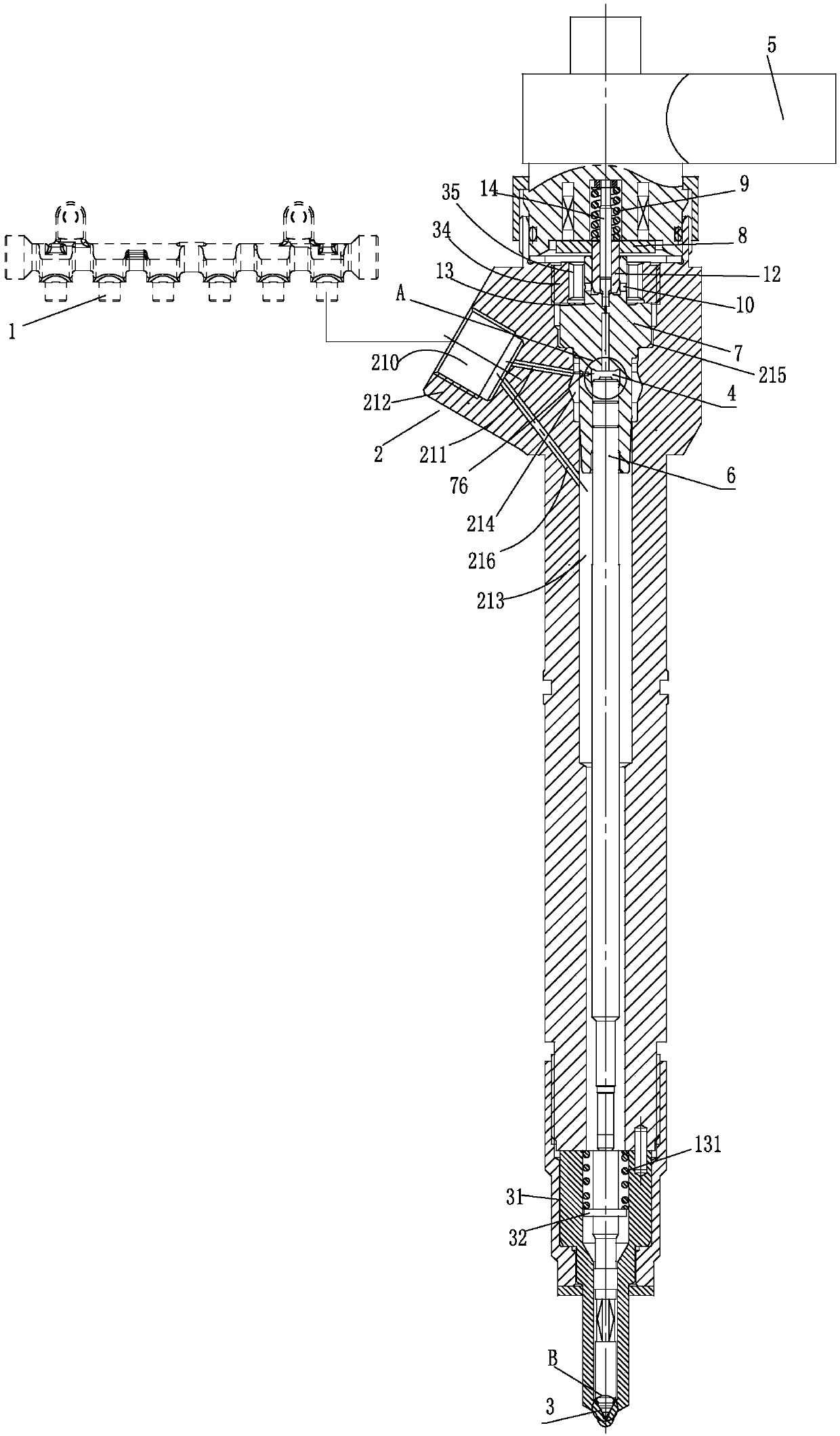

[0033] Such as Figure 3 to Figure 8 , Figure 10As shown, a pressure balance valve type common rail fuel injector includes a fuel injector body 2, a piston rod 6, a nozzle coupling, a pressure balance valve coupling, and a solenoid valve assembly. The upper part of the fuel injector body 2 is connected to the solenoid The lower part of the valve assembly is connected, the lower part of the pressure balance valve couple is connected with the upper part of the injector body 2, the lower part of the fuel injector body 2 is connected with the nozzle coupler, the nozzle coupler includes a needle valve 3, and the injector body 2 is axially In the center, there is a stepped cavity whose diameter decreases successively from top to bottom. The stepped cavity is formed by connecting and combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com