Adjustable material collection device for rotary kiln

A collection device and rotary kiln technology, which is applied in the direction of rotary drum furnace, furnace, lighting and heating equipment, etc., can solve the problems that iron slag has no collection device, can not be discharged effectively and reliably, and is not conducive to the subsequent utilization of resources, so as to achieve operation Convenience, ease of use, and ease of classification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

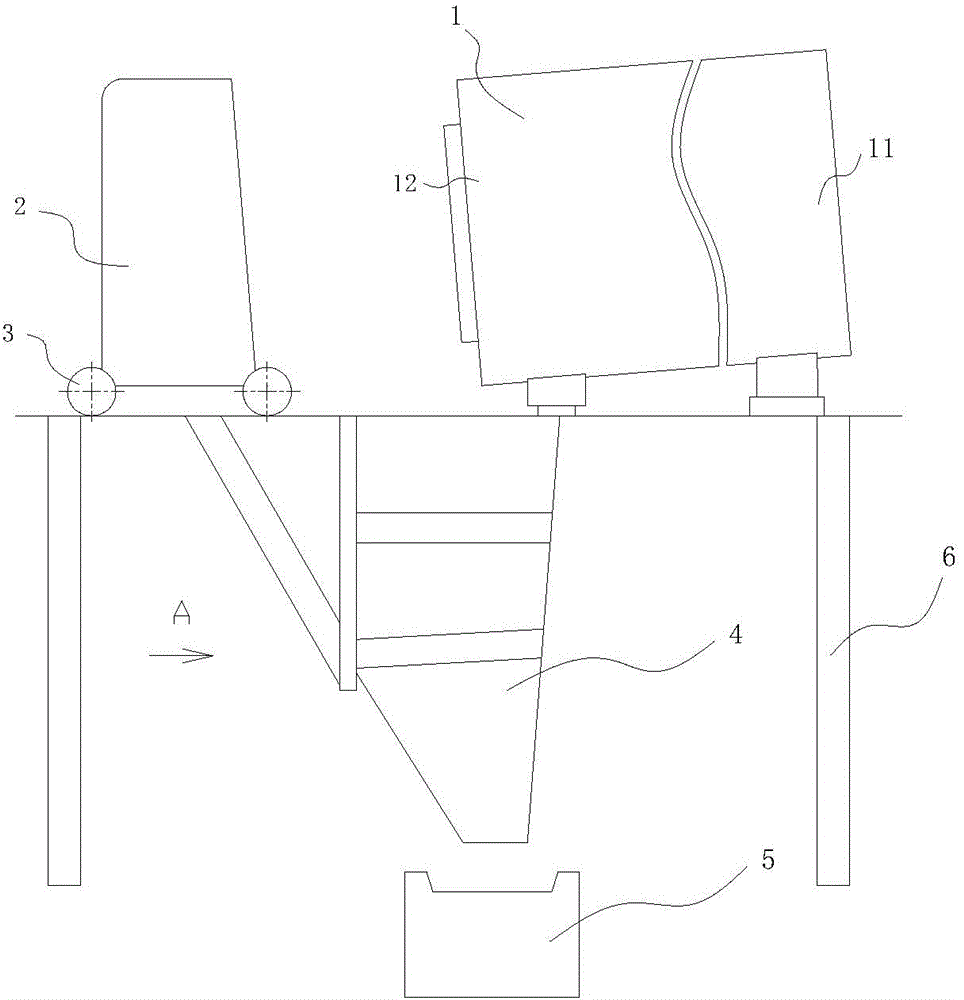

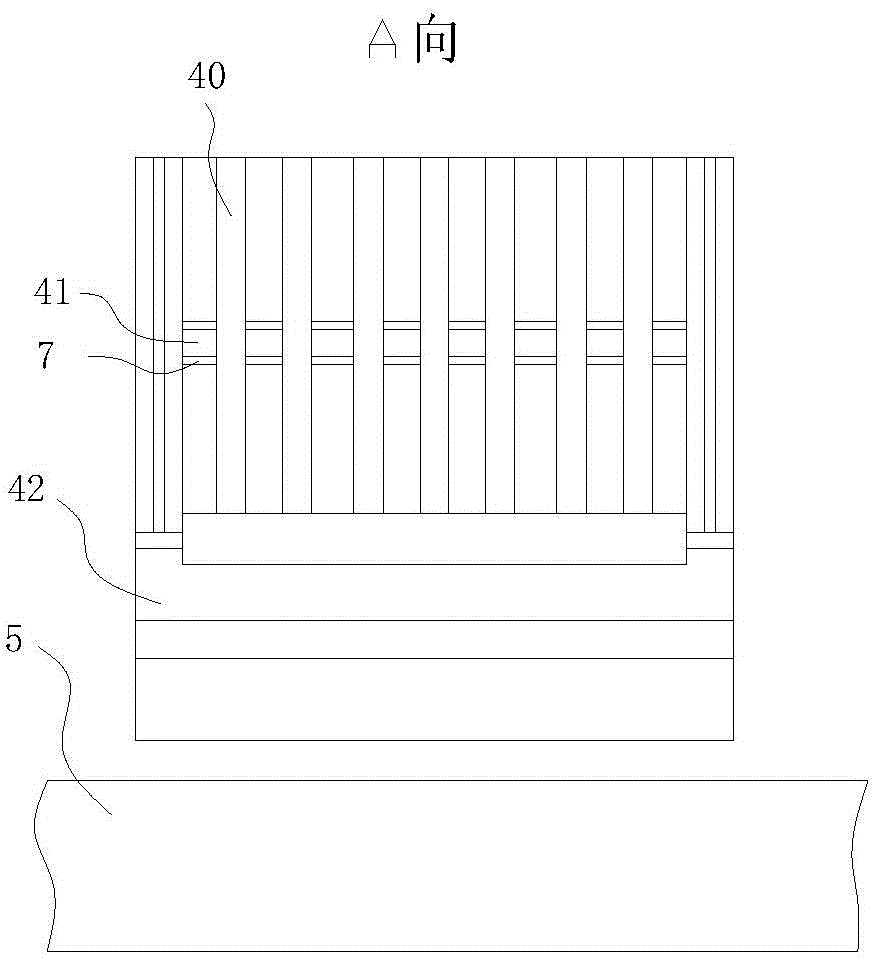

[0013] The present invention as Figure 1-3 As shown, the rotary kiln includes a rotary kiln body 1 and a kiln head cover body 2, and the rotary kiln body 1 is arranged on a horizontal support 6; the rotary kiln body 1 has a feed port 11 and a discharge port 12; The collection device 4 includes a collection bin 42 and a conveyor belt 5, the collection bin 42 is in the shape of a funnel with a large top and a small bottom, and the conveyor belt 5 is arranged under the collection bin 42. It is arranged under the discharge port of the rotary kiln body, and the conveyor belt is arranged under the collection bin;

[0014] During operation, a kiln head cover 2 is provided at the discharge port 12 of the rotary kiln body, and a wheel 3 is provided at the lower part of the kiln head cover 2, so that the opening and closing of the rotary kiln body 1 can be realized conveniently and quickly.

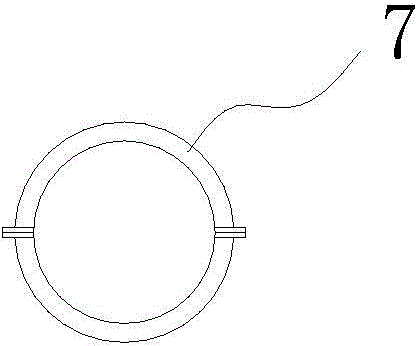

[0015] The mouth of the collection bin 42 is evenly equipped with some grid bars 40, and some...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com