Acoustic emission monitoring device and method for hydraulic fracturing fracture field of gas-containing coal body

A technology of hydraulic fracturing and monitoring device, which is applied in the direction of material analysis, analysis of materials, and instruments using acoustic wave emission technology, can solve the problems of inaccuracy and incomplete monitoring of the fracturing range of coal seam hydraulic fracturing field distribution law, etc. Achieve the effect of convenient operation, abundant ground stress simulation functions, high experimental accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

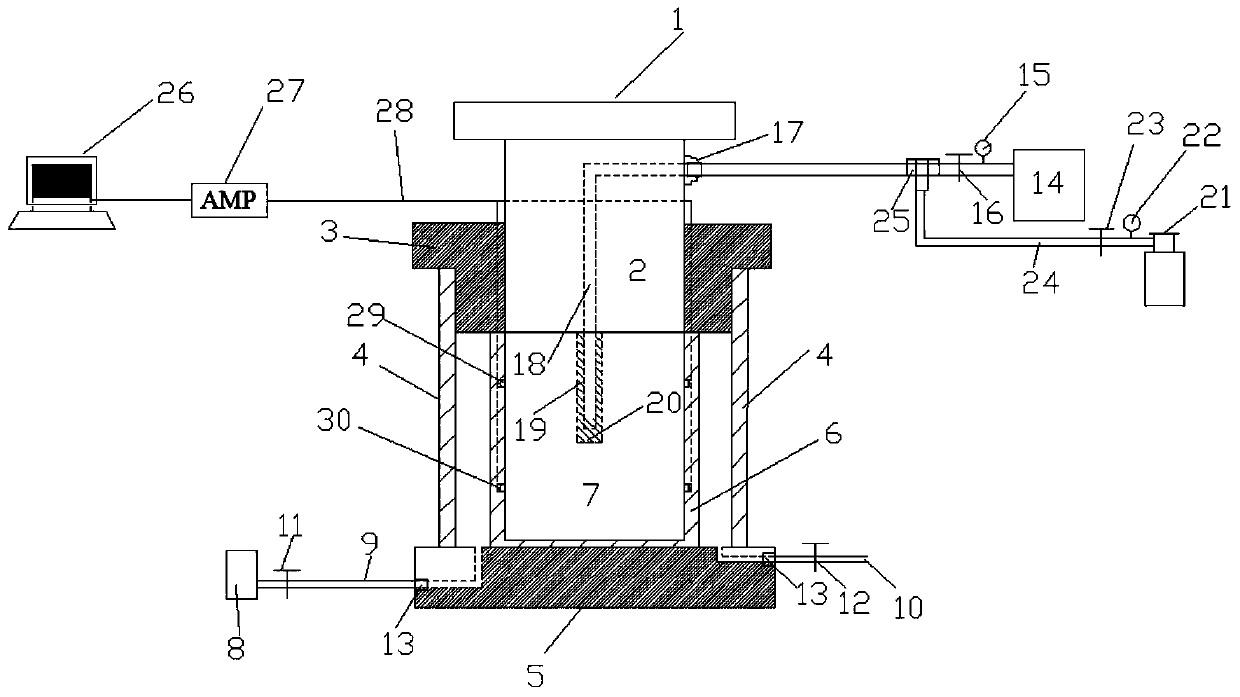

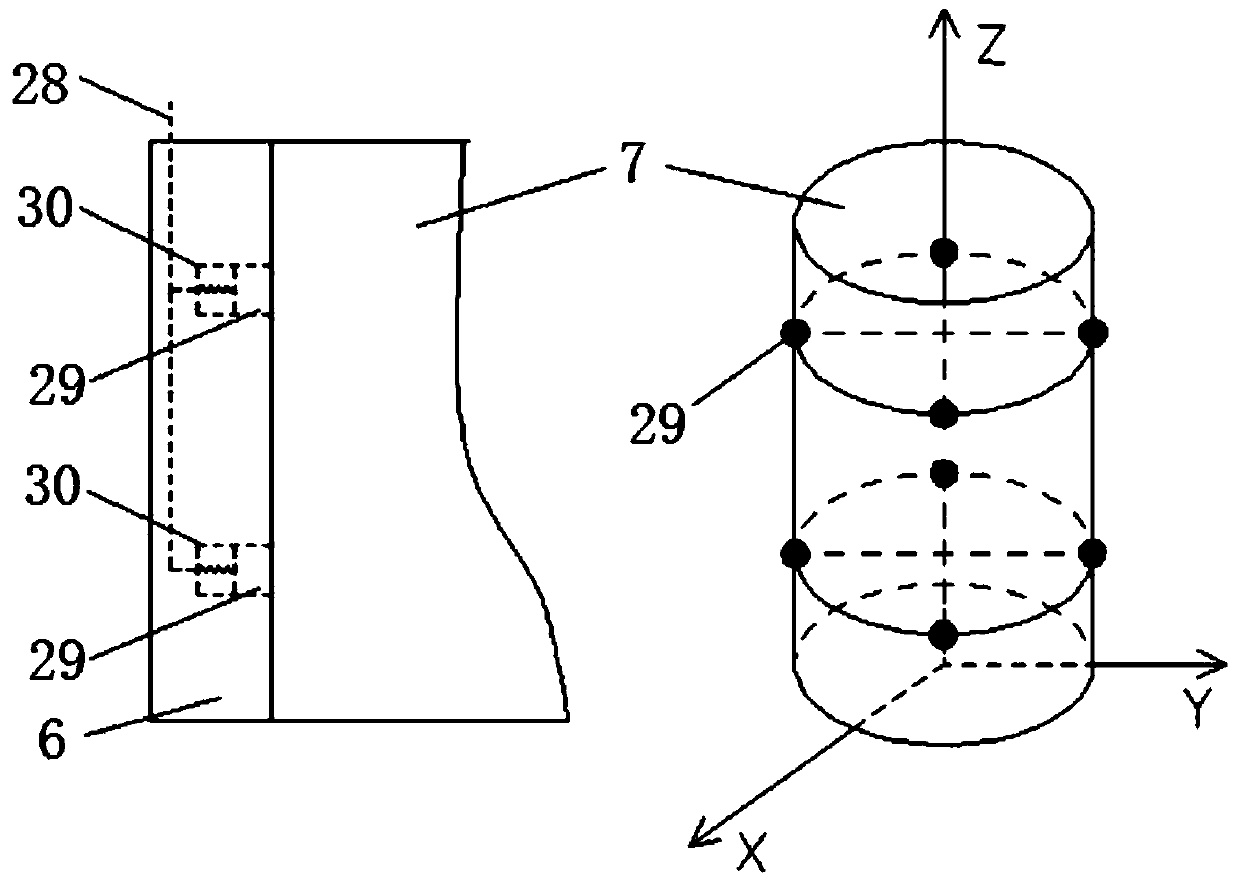

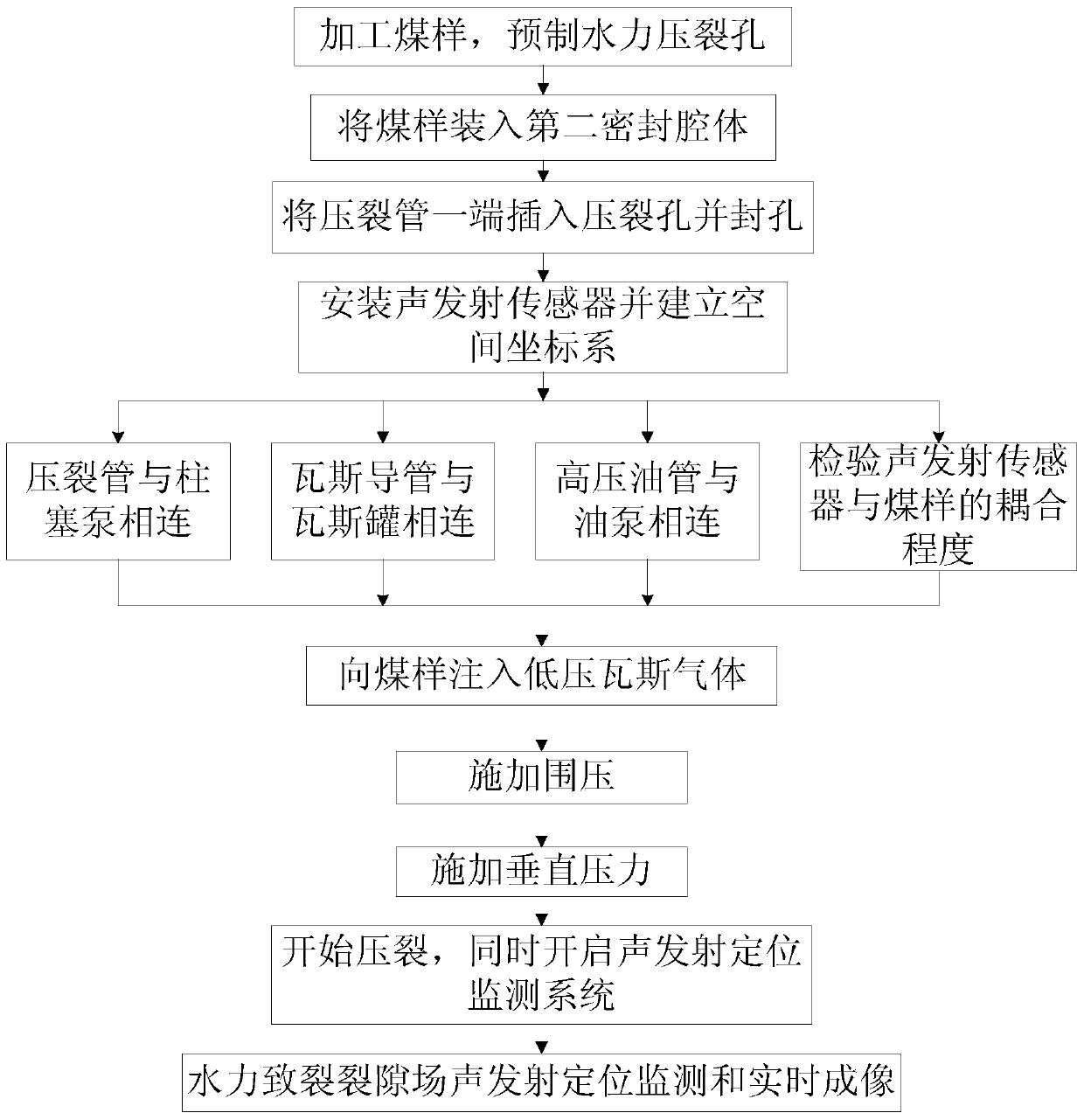

[0068] Embodiment 1: The first sealed cavity is surrounded by the base 5, the steel plate 4 on the base 5, the rubber tube 6 and the upper cover 3; The left channel and the right channel, the entrances of the left channel and the right channel are respectively provided with sealing bolts 13.

[0069] The second sealed chamber is in the first sealed chamber and is surrounded by a base 5, a rubber cylinder 6 with an open upper end surface on the base, an upper cover 3 and a plunger 2, and the upper cover 3 and the plunger 2 are sealed The ring is sealed.

[0070] The ground stress simulation module includes a loading press 1 and a plunger 2 for applying vertical pressure, an oil pump 8 for applying surrounding rock stress, a high-pressure oil pipe 9 and a drain pipe 10; the plunger 2 passes through the upper cover 3 and enters the second chamber In the body; the upper cover 3 of the first sealed cavity and the mating surface of the plunger 2 are provided with a sealing ring; on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com