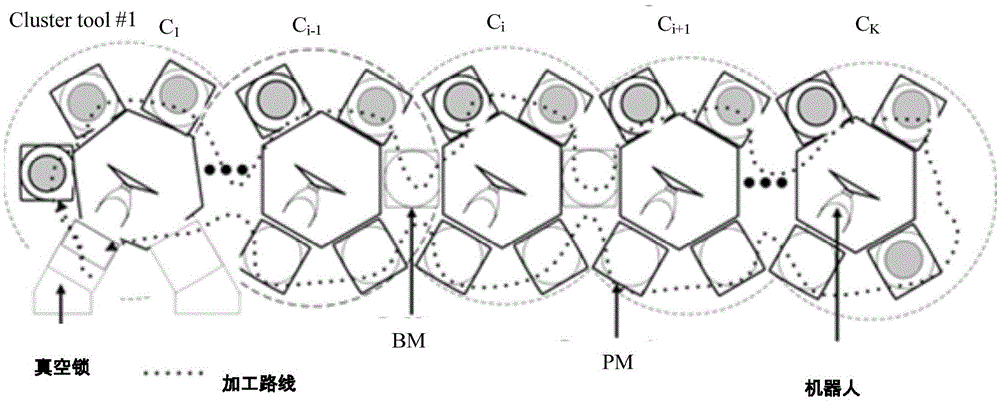

Optimal buffer space configuration and scheduling for single-arm multi-cluster tools

A technology of combining equipment and buffer space, applied in design optimization/simulation, manufacturing tools, general control systems, etc., can solve problems such as payment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

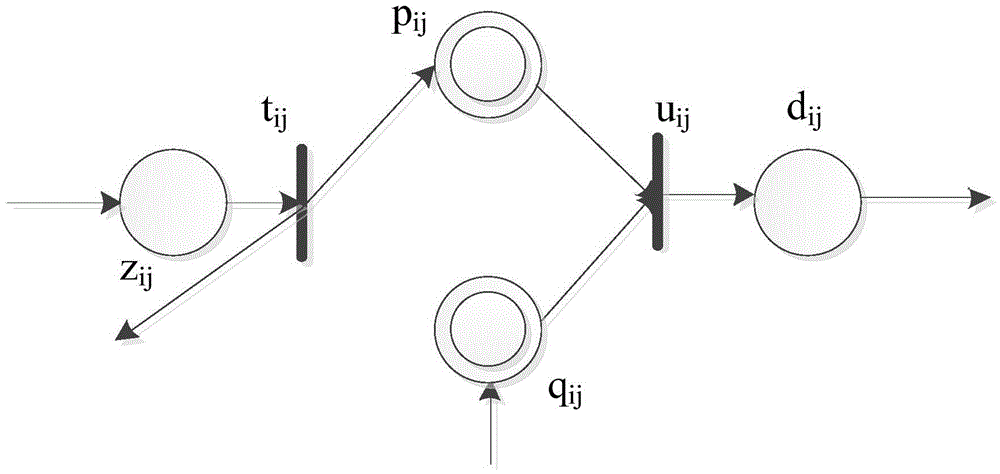

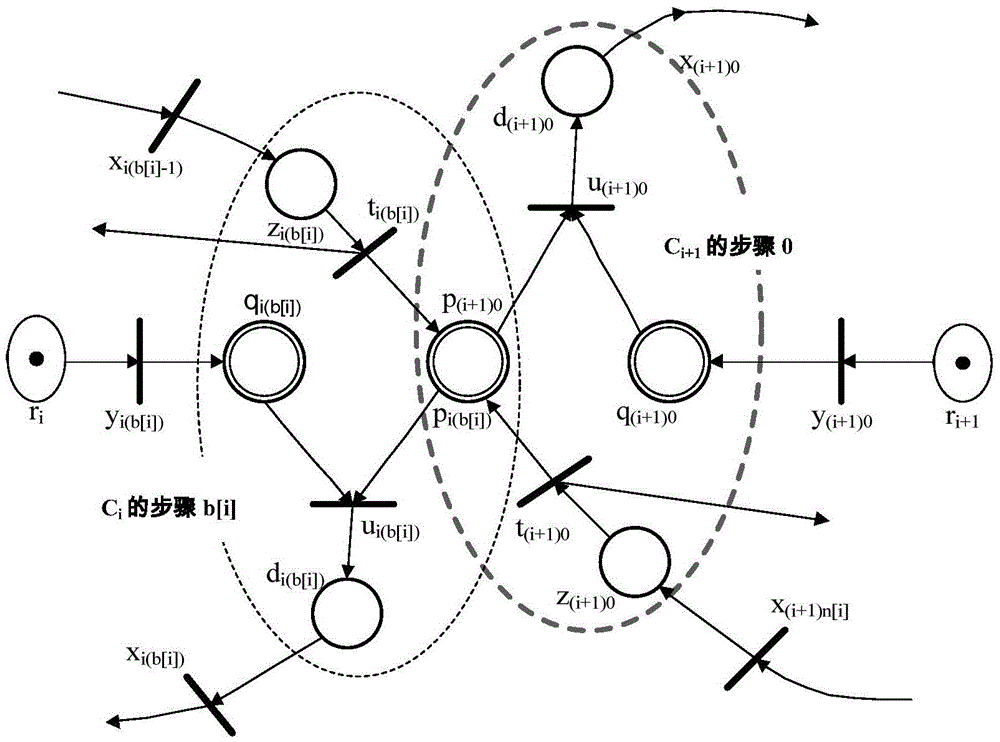

Method used

Image

Examples

example 1

[0155] Example 1: According to the scheduling problem of 3-combination devices proposed in the literature [Chan et al., 2011b]. The activity time of each device is as follows: For C 1 In terms of α 10 = 0 (vacuum lock), α 11 =34s, α 12 =0(BM 1 ), α 13 =31s, α 14 =4s, λ 1 = 10s and μ 1 = 1s; for C 2 In terms of α 20 =0(BM 1 ), α 21 =82s, α 22 =0(BM 2 ), α 23 =54s, α 24 =12s, λ 2 =7s and μ 2 = 1s; and for C 3 In terms of α 30 =0(BM 2 ), α 31 =54s, α 32 =38s, α 33 =91s, α 34 =90s, λ 3 = 3s and μ 3 = 1s. According to the single-space BM scheduling problem solved in the literature [Chan et al., 2011b], a multi-product cycle scheduling with a cycle time of 114.8s is obtained. The solutions covered in this article are as follows:

[0156] for C 1 In terms of such that ζ 10 = α 10 +4λ 1 +3μ 1 =0+4×10+3×1=43s, ζ 11 = α 11 +4λ 1 +3μ 1 =34+4×10+3×1=77s, ζ 12 =43s, ζ 13 =74s, ζ 14 =47s and ψ 11 =2(n[1]+1)(μ 1 +λ 1 )=2×(4+1)×(10+1)=110s. Therefor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com