Arc laser based on gas discharge tube

A gas discharge tube and activator technology, which is applied in the electronic field, can solve problems such as not being suitable for program control and not being able to realize automatic control, and achieve the effect of stabilizing the breakdown voltage value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

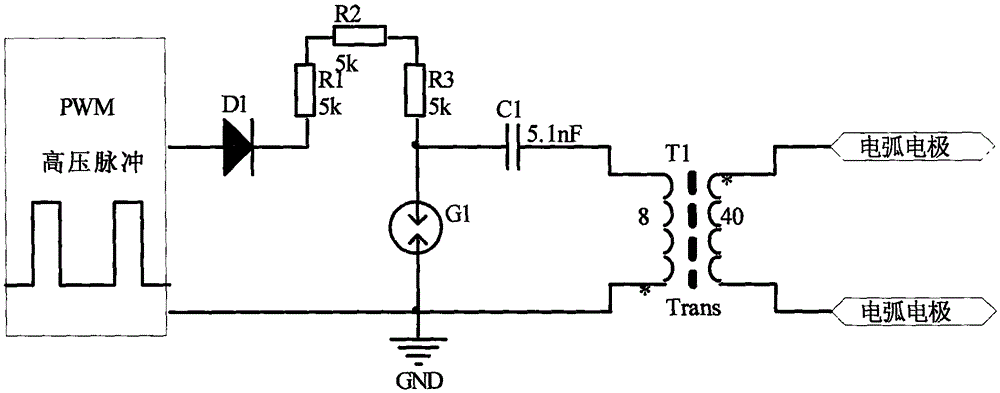

[0021] According to the working requirements of the arc activator, the rated breakdown voltage of the gas discharge tube in the present invention is 2500V-3000V, the shape of the gas discharge tube is a cylindrical ceramic package structure of 17.4mm×Φ11.8mm, and the two ends are connected by 3mm bolts To facilitate installation, for example, use V10-H30X type.

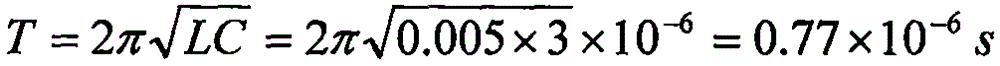

[0022] The high-voltage energy storage capacitor has a great influence on the working stability, and should be able to withstand a large working current. It is advisable to use a CYS-2 high-voltage mica capacitor. The capacitor is 5100pF, and the withstand voltage is required to be above 4kV. Or use other high-voltage resonant capacitors, but due to the requirements of current carrying capacity, it is not suitable to use energy absorbing capacitors.

[0023] In order to meet the requirements of high withstand voltage, the current limiting resistor is preferably composed of 3 to 4 metal film resistors above 2W in serie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com